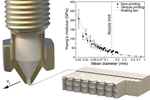

It’s long been established that retained fiber length has a direct impact on mechanical properties of composites. Shown above, flexural modulus is plotted against notched Charpy impact strength for a variety of short- and long-fiber thermoplastics as well as sheet molding compound (SMC), bulk molding compound (BMC) and a new developmental grade of long-fiber thermoplastic (LFT) with glass fiber-reinforced liquid crystal polymer (LCP). Photo Credit, all images: Sumitomo Chemical Co. Ltd.

The Energy & Functional Materials Research Laboratory of Sumitomo Chemical Co., Ltd. (Chūō City (Tokyo), Japan) has developed several grades of long-fiber thermoplastic (LFT) compounds with fiberglass or carbon fiber reinforcement and a matrix of liquid crystal polymer (LCP). The company says the new materials are currently being evaluated by customers in several industries.

High-performance matrix

LCPs are high-performance polymers with unique structures and many processing benefits. They are thermotropic and fully aromatic thermoplastics whose scrap can be melt reprocessed (recycled). The vast majority of commercial LCPs are polyesters. They are said to offer the highest thermal stability of any engineering thermoplastic, and are also known for their excellent electrical insulation, broad chemical resistance, good weatherability and stress-crack resistance, plus high inherent flame/smoke/toxicity (FST) performance.

Since they form liquid crystalline structures, molecules align in the direction of flow during solidification. As a result, they essentially function as self-reinforcing materials that offer optimized mechanical performance in the direction of molecular orientation (flow). Although they usually offer sufficiently high stiffness and strength so as not to require fiber reinforcement, they are typically supplied with such to help reduce the anisotropy caused by the long crystalline structures’ molecular orientation.

As their melting point is approached, the viscosity of LCPs drops significantly, enabling them to be injection molded at relatively low pressures and very fast cycle times of 5-10 seconds, which helps offset their higher cost. LCPs also can be melt-spun into fiber, extruded or cast into thin sheets/films or applied as coatings.

Typical uses of LCPs include a broad variety of electrical and electronic components (e.g., fiber optic cable, printed circuit boards, chip carriers, connectors, central-processing unit (CPU) sockets, relays, bobbins and surface-mount components). They also are widely used in printer, fax and copier components for office equipment, and for ignition and transmission system components, lamp sockets, pump components, coil forms and sensors in the automotive industry. The polymer is even used as coatings for high-temperature, non-stick surfaces on bakeware, as sterilizable medical and drug-delivery devices, as pumps, valves and meters for chemical processing and as high-barrier/retort-processed food containers.

Sumitomo Chemical, which calls its own line of LCPs SumikaSuper, has recently commercialized a chemically soluble grade — said to be the first in industry — that can be used to produce coatings or films for flexible and rigid electronic components and to protect speaker membranes.

More efficient use of increased fiber length

Available to industry since the 1990s, the vast majority of pelletized LFT compounds are processed by injection or compression molding and consumed in the automotive segment for a variety of semi-structural components like front-end modules (FEMs), center console side panels and underbody shields. Non-automotive uses include components for bikes and compound bows as well as housings for power tools. Among those uses, the vast majority are fiberglass-reinforced polypropylene (LFT-PP) with a small but growing percentage of glass/polyamide 6 or 6/6 (LFT-PA6, LFT-PA6/6). Despite many decades of commercial use, very few offerings in higher temperature thermoplastics have been commercialized with the exception of several products in polyphenylene sulfide (PPS), which are used in the automotive, industrial and recreational markets. Other work has reportedly been done with LFTs based on polyetheretherketone (PEEK), polyetherimide (PEI) and LCPs, although none of those products were commercialized.

Given the dominance of PP and PA matrices, the higher cost of LFTs versus short-fiber thermoplastics, and the premium price between LCPs versus PP and PA, why did Sumitomo researchers decide to develop an LFT-LCP?

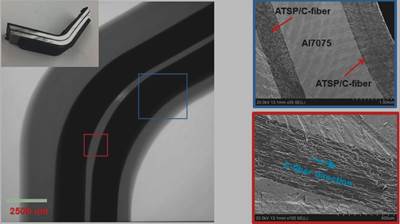

“We know that properties increase with greater fiber length and we also know that LFT-PP injection molding grades rarely preserve fiber lengths greater than 2 millimeters, so the benefits of fiber reinforcement in parts is not fully demonstrated,” explains Takayuki Sugiyama, Sumitomo product manager. “We felt we could take advantage of the low melt viscosity of LCP to help preserve long fibers.” He says the team started working on these materials about four years ago and that the hardest issue they had to overcome was selecting fibers that could maximize the performance of LCP.

Presently, there are two developmental grades. SumikaSuper SCG-379 is reinforced with 30-50% fiber-weight fraction (FWF) E-glass, and SCG-420 is reinforced with 30-40% FWF high-modulus carbon fiber; additional details on fiber type or tow were undisclosed. Researchers at Sumitomo Chemical say it should also be possible to create a masterbatch that could be blended with neat LCP to create custom FWF grades, although they also said they are very flexible in terms of offering custom FWF and will work hard to meet customer needs.

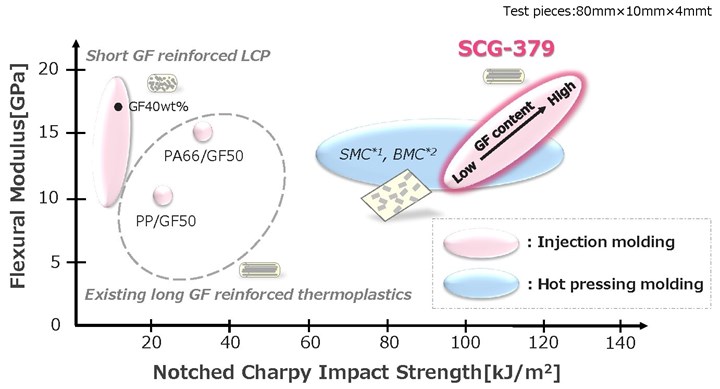

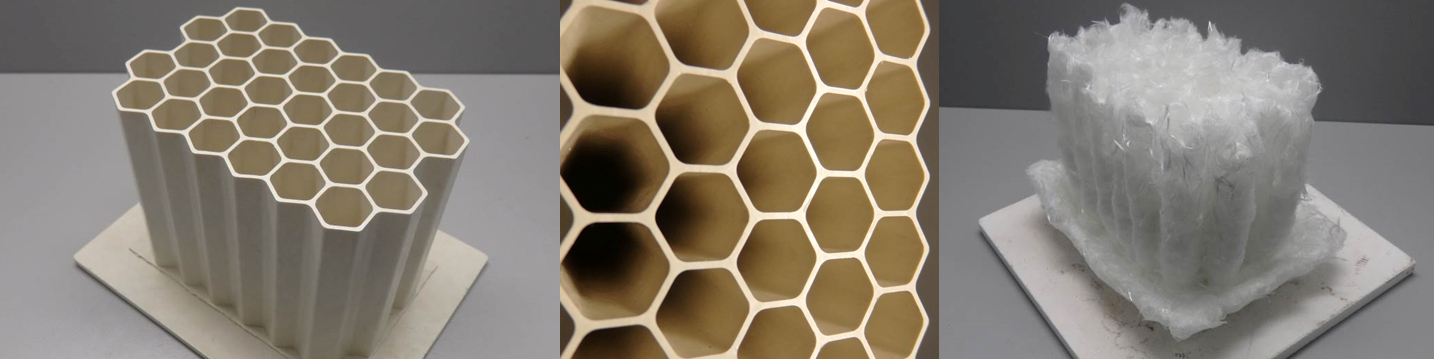

Sumitomo researchers have evaluated the specific energy absorption of various materials (LFT-PA6, glass/LFT-LCP, plus aluminum and steel) as well as the effects of various geometries on the ability to manage energy. The new glass/LFT-LCP grade offered higher energy absorption than competitive materials when it was molded into either a cone or honeycomb structure. The low-melt viscosity polymer is adept at filling complex geometries via injection molding.

Neither material is expected to compete against other LFT products, but rather are being positioned against lightweight aluminum, magnesium and even steel alloys, where they can offer mass reduction, eliminate corrosion concerns, reduce manufacturing steps and provide comparable or higher mechanical performance, plus fast processing times to help offset initial higher costs.

Sumitomo researchers have done interesting work molding the materials into a variety of crash-management structures and then conducting crush tests on them, finding they offer excellent energy absorption and have very controlled crush characteristics with ductile failure modes that don’t produce sharp shards. This suggests the possibility of their use in crash structures on passenger vehicles, such as bumper crash boxes and rocker and pillar reinforcements. LCPs have the thermal and chemical stability to handle e-coat (electrophoretic coating for rust prevention) and paint bake oven temperatures, so can be assembled in the body shop with the rest of the body-in-white (BIW). They may also be useful in seat components or to mold large sunglass roof rails and support structures that help lower a vehicle’s center of gravity and increase road stability. Beyond automotive, performance sporting goods and industrial equipment (such as end of arm tooling/EOAT) are other potential targets.

Sumitomo researchers also have explored injecting their LFT-LCP materials into complex, energy-absorbing structures like the honeycomb above (left and center). They have demonstrated (via burnout tests) the high amount of glass penetration they have achieved (right), and via crush tests the large amount of energy and the controlled crushing behavior of the materials.

Asked what the company’s commercialization plans were moving forward, researchers had this to say: “Right now we are working very hard to collect more technical data to prove these materials are good options to address existing industry challenges as well as creating new opportunities,” explains Tomohiro Sato, Sumitomo senior manager. “We also have developmental quantities of the materials available for testing.”

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreNovel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

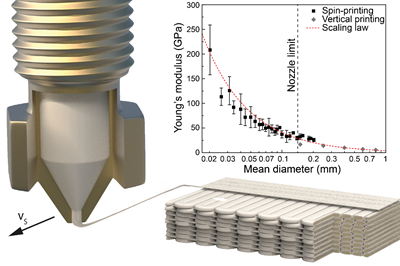

Researchers develop liquid crystal polymer spin-printing process for recyclable composites

ETH Zürich, TU Delft and EMPA simultaneously 3D prints parts with spun fiber reinforcement for stronger, more sustainable, fully recyclable components.

Read MoreNew polymer expands composites options in demanding environments

Aromatic thermosetting copolyester offers unique properties, availability in multiple form factors.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)