Composites distributor highlights product offerings, technical support

CAMX 2024: Stop by Composites One’s booth to see featured composite solutions, watch live demonstrations at the Demo Zone next door and better understand the level of technical support the distributor provides to composites customers.

Share

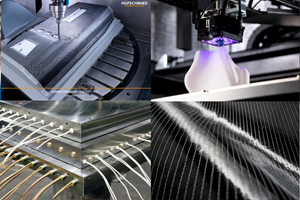

Stop by Composites One’s (Schaumburg, Ill., U.S.) booth where the company will be featuring latest products from more than 700 industry suppliers. In addition, displays will showcase safety and aerospace solutions, as well as Composites One’s own brand, Aerovac.

Technical sales representatives will be available to answer questions and offer product-related suggestions. Located throughout North America, they are adept in the latest technologies, products and equipment available in today’s marketplace. Together, the reps are said to comprise one of the largest teams of CCT-certified sales representatives in the industry.

The Composites One sales team works one-on-one with customers, helping them with issues beyond what would be expected from a composites distributor. Sales representatives share their expertise with customers, providing them with solutions that can help increase their competitive edge.

Regionally based technical support managers provide added support and help to ensure that customers get the answers they need when they need them. In addition to its extensive product line, Composites One offers the technical assistance to educate customers on the proper use of these products in their shop.

Also leading the Closed Mold Alliance, Composites One provides manufacturers with the resources and training to help them successfully convert to closed molding. Live process demonstrations will be presented on the exhibit hall floor.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Winding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

Related Content

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreWinding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.

Read More"Good Day, CAMX" to discuss current challenges and future opportunities

On Nov. 1, CAMX 2023 presents an engaging and interactive discussion between Composites One’s Marcy Offner and CW’s brand VP Jeff Sloan concerning the current composites industry landscape.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More