Resin Infusion

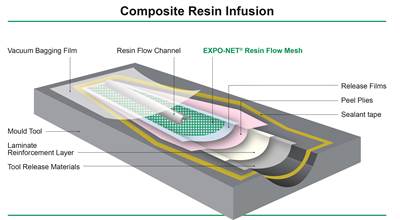

Resin infusion is a method used in composite manufacturing to impregnate dry reinforcement materials, like fibers or fabrics, with a liquid resin. This process involves placing the dry reinforcement in a mold and then introducing the resin under vacuum pressure, allowing it to permeate the reinforcement thoroughly. The vacuum facilitates the removal of air pockets and ensures uniform resin distribution, resulting in a high-strength composite with consistent properties. Resin infusion offers advantages in creating complex shapes, minimizing waste, and producing lightweight yet durable structures.

Latest Infusion Articles

VIEW ALLGurit reformulates epoxy products with bio-content

Prime resin infusion and Ampreg wet laminating portfolios are now made more environmentally conscious as a standard.

Read MoreComposite Integration adds real-time resin degassing measuring to Ciject equipment

Ciject resin infusion and injection machinery now offers real-time resin degassing measurement technology that uses sensors and software to continuously monitor the state of resin during the degassing process.

Read MoreSunreef Yachts completes 43-meter single-shot hull infusion project

Sunreef 43M Eco electric catamaran, with a composite surface of 1,700 square meters, is considered to have the world’s largest infused hull.

WatchMelker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreAmpliTex-constructed solar-powered ferry hits the Adriatic Sea

The Marservis PROeco is a mass transportation marine vessel using Bcomp natural fiber for interior parts in place of standard materials.

Read MoreToray obtains ABS type approval for in-situ VARTM ship repairs

American Bureau of Shipping (ABS) certifies use of jointly developed CFRP repair technique on FPSO and FSO industrial systems, addressing traditional steel restoration challenges.

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORELatest Infusion News And Updates

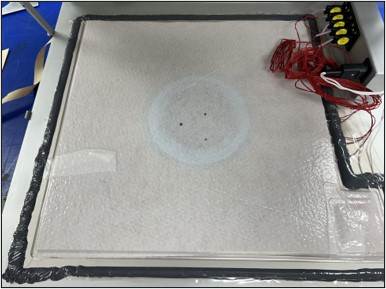

Ultrasound imaging optimizes vacuum bag leak detection

CAMX 2024: The handheld Ultra CE by Distran combines acoustic information with a wide-angle optical camera to clearly and reliably detect leaks at a distance.

Read MoreIPD system, robotic spray demonstration enhances composites productivity

CAMX 2024: Magnum Venus Products (MVP) presents several automation solutions, including a self-learning robot, an IPD system and several live demonstrations of its products.

Read MoreStitched, needle-punched fabrics benefit open and closed molding

CAMX 2024: Vectorply Corp. displays a range of engineered reinforcements, including NCFs, needle-punched reinforcements, consumables and more, along with highlighting it technical support options.

Read MoreMel Composites infusion strategy enables Sasga Yachts fiberglass hull designs

Mel’s ongoing partnership culminates in the development of the Menorquín 42 and Menorquín 54 motor yachts, as well as extension of Sasga’s capacity for 68-foot-length boats.

Read MoreTechnology Marketing Inc. to distribute VacPuc digital sensors

VacPuc is expanding its range of global distributors to deliver its vacuum pressure measurement solution to the composites market.

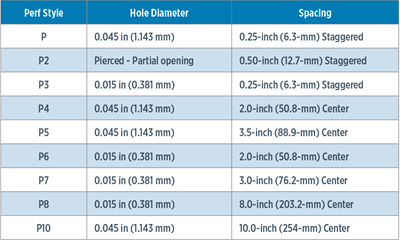

Read MoreInfusion processing flow mesh range, technical composites expertise

JEC World 2024: Expo-Net promotes 100% recyclable extruded thermoplastic resin flow mesh products, an updated technical processing guide and highlights its successful work with industry partners.

Read MoreFeatured Posts

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreCarbon fiber satellite arm reduces weight, simplifies assembly onto naval vessels

Satcom developer EM Solutions partnered with ACS Australia to replace an aluminum arm design with a 65% lighter, one-piece, corrosion-resistant carbon fiber/epoxy alternative.

WatchRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreEngine vane demonstrates potential for gapped, unidirectional dry fiber for infusion

GKN Aerospace and its partners developed an aircraft demonstrator component made with TeXtreme’s latest Gapped UD material, proving out a dry, infusible tape meant to compare in performance to UD prepreg.

WatchUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read More

.jpg;maxWidth=300;quality=90)