Plant tour: Tods Aerospace, Crewkerne, U.K.

Tods Aerospace, located in rural England, is part of the larger Unitech Aerospace manufacturing group and specializes in highly engineered aerospace defense structures.

The complexities of composites manufacturing make it nearly impossible for all fabricators to be all things to all customers. The variety of material and process types almost mandates some degree of specialization, or a very substantial investment if the goal is to offer customers a full suite of processing options. To better take advantage of the growing number of composites opportunities in an increasingly broad range of end-markets, several ambitious commercial entities — in financial markets, they are called aggregators — have used mergers and acquisitions in the past few years to build multi-company conglomerates to provide a range of composites manufacturing services in a variety of geographic locations.

UK-based Tods Aerospace, located 2.5 hours (by train) south and west of London, in the small town of Crewkerne, is the beneficiary of such an aggregation. Acquired by Unitech Aerospace (Hayden, ID, US), it is one of a robust collection of plants and operations designed to supply aerospace and defense customers with high-quality composites and metallic manufacturing solutions. Unitech’s holdings include Tods Aerospace sister company Tods Defence (Portland, UK), Unitech Composites (Hayden), Paul Fabrications (Castle Donington, UK), and the RTM/tooling materials powerhouses North Coast Composites (Cleveland, OH, US) and North Coast Tool & Mold (Cleveland). Capabilities at these facilities range from design engineering to hand layup to 5-axis metals machining to resin transfer molding — and more. The net effect is that each facility ultimately has the ability to provide — by itself or through a partner company — a full range of design and manufacturing services to meet almost any customer’s aerospace production requirement.

With that kind of backing, Tod Aerospace epitomizes the Unitech mission, offering a full slate of technical and manufacturing services, producing everything from cabin doors to cockpit doors, fairings, engine acoustic liners and seat floor systems.

CW’s visit is hosted by Ryan Stalker, a principal manufacturing engineer who has more than 18 years’ experience at Tods. Stalker greets CW at the Crewkerne rail station and explains, during the short drive to Tods, that the facility is spread out over two buildings, within a quarter-mile of each other in a small industrial park near the edge of town.

Stalker points the way into Tods’ Cropmead building, where, after signing in, we are met by Adrian Hussey, operations manager and an 11-year employee. Over tea, Stalker explains that Tods made a big leap in capability in 2016 when it earned Nadcap accreditation, which compels the company to systematically build best practices, conduct risk management, document processes, and share knowledge among staff.

Hussey and Stalker then tick off the parts and programs served by Tods. Among them are acoustic liners for the Rolls-Royce Trent 700 engine; cabin doors, a cockpit door and fairings for a Leonardo SpA (Rome, Italy) helicopter program; more recently, a radar housing for the AgustaWestland (Farnborough, UK) AW101 helicopter; interior floor plinths for Zodiac Aerospace (Plaisir, France); and refueling pods for the Airbus (Toulouse, France) A400M and the Embraer (São Paulo, Brazil) KC-390, both military transport aircraft.

On the floor of Cropmead

Leaving the second-floor administration area and heading to the Cropmead building’s first floor production area, Stalker starts the tour in the building’s Class A cleanroom, where technicians are laying up prepreg on a metal tool for fabrication of a starboard fairing.

Next, in its nondestructive testing (NDT) lab, Tods employs computed tomography, X-ray imaging and physical testing to evaluate part quality and conformance. Tods uses testing machines from Shimadzu Scientific Instruments (Columbia, MD, US) to perform tensile and flexural tests, as well as hardness tests. C scans are performed with equipment supplied by NDT Systems Inc. (Huntington Beach, CA, US). X-ray imaging (computed radiography) is performed with a gantry-mounted, flexible-head system that is used, primarily, to check for cracks in honeycomb cores.

CW is led next to the largest room in the building, where everything from autoclave cure to product assembly is performed. The space features a large mezzanine that is used primarily for mold and tool storage. There are two autoclaves here, the largest and most used of which is a 6-by-2m unit from ASC Process Systems (Valencia, CA, US). Adjacent to this are several storage racks equipped with vacuum lines for post-curing. Debagging is done here as well.

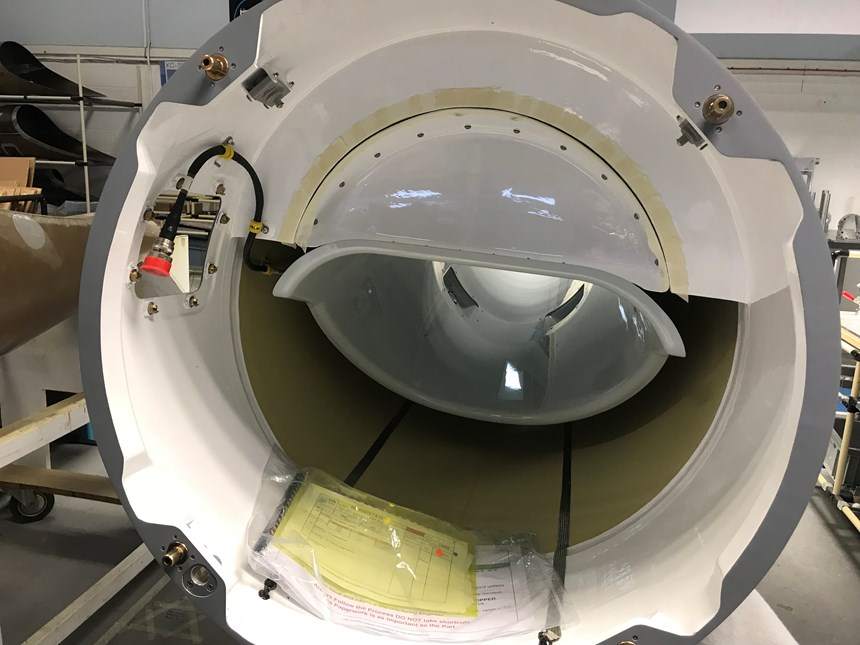

In the assembly area are several refueling pods in various stages of assembly. These are the tubular structures that protrude from above the front cockpit windows on the A400M and the KC-390 transport aircraft, into which an aerial refueling line is guided to deliver jet fuel during in-fight refueling operations. One of the partly assembled pods is for the A400M and weighs in at 50 kg, significantly less than its metallic predecessor. Stalker says Tods has built 42 of these pods, and notes that the production rate fluctuates with demand. The KC-390 pod is in pre-production phase. Like the A400M pod, when it is complete, it will include lightning strike protection and an integrated light.

From here, the tour is led into the CNC machining area. A large, 5-axis, enclosed CMS (Zogno, Italy) system is cutting core materials for a heat-shield application. Undergoing preparation for machining nearby is honeycomb core (supplied by Hexcel, Stamford, CT, US) for the Trent 700 acoustic panels.

A walk to Blackwell Lane

Stalker next leads the way (on foot, through a light rain) out of the Cropmead building, down the street and around a corner to Tods’ second building, named for the street on which it’s located, Blackwell Lane. It’s here in Blackwell Lane that Tods does most of the fabrication of the acoustic panels for the Trent 700. Stalker notes that there are six panels per shipset, each of which comprises a 1m curved fraction of the completed circular structure.

What’s interesting here is how Tods perforates the epoxy film, which is a necessary step to maintain the acoustic performance of the panels. Stalker explains that Tods places the film on top of the curved aluminum skin, which is already perforated. This structure is then placed aluminum side down over a hot-air knife, which passes slowly over the surface of the aluminum, directing hot air through the perforations in the metal and into the film, perforating it as well. Stalker says this in-house-developed process has proved to be highly efficient and has helped Tods meet its weekly goal of five engine sets per week.

The Zodiac floor plinths are fabricated here as well. They consist of a honeycomb core sandwiched on each side by a press-bonded thermoplastic skin. The final, irregularly shaped part measures about 1 by 0.5m and features several potted metallic inserts that will enable the eventual mechanical attachment of aircraft seats during aircraft final assembly.

Other equipment in this building includes another CMS CNC machine, used in this case to cut core materials for the plinths, a Zünd (Altstätten, Switzerland) cutting table, and a Premier Autoclave & Oven Solutions (Sandbeds, UK) oven to cure the acoustic panels.

As CW’s tour ends, Stalker leads the way back to the Cropmead building before the short drive to the Crewkerne railway station. Tods, it is clear, has carved out a niche in southwestern England and has the roots and experience to help it thrive. Tods Aerospace and its sister companies appear to be poised for growth.

Related Content

Time Bicycles to modernize composite bicycle manufacturing

With the aid of KraussMaffei, Clemson University and SC Fraunhofer USA Alliance, Time anticipates a transition to HP-RTM for more efficient carbon fiber bike frame manufacture, plus a new facility in South Carolina.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreAddyx carbon exoskeleton technology enables molded ribs inside hollow composite structures

Using a water-soluble mandrel, carbon exoskeleton opens paradigm for topology-optimized composites, cutting weight, manufacturing time and scrap rate.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More