Addyx carbon exoskeleton technology enables molded ribs inside hollow composite structures

Using a water-soluble mandrel, carbon exoskeleton opens paradigm for topology-optimized composites, cutting weight, manufacturing time and scrap rate.

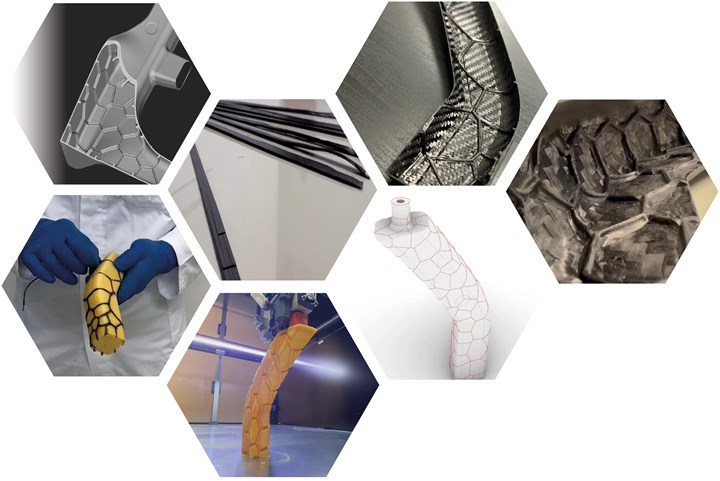

Addyx has developed innovative technology enabling molded carbon fiber-reinforced ribs — inside hollow tubes, for example — using a system of additive manufacturing (AM) and novel wash-out mandrel. Photo Credit: Addyx

Addyx Srl (Montesilvano, Italy) has developed carbon exoskeleton, an innovative technology for advanced composite structures, comprising topology-optimized, unidirectional (UD) carbon fiber-reinforced composite ribs on the inside of molded, hollow components.

Obtained using Addyx’s WSM-170 water-soluble expanding mandrel, the carbon exoskeleton technology enables new freedom in the design and production of hollow, composite components with complex geometry. Moreover it is said to advances topology optimization in composite structures, improving mechanical performance including the stiffness- and strength-to-weight ratio but also a lightweight, integrated means to improve impact resistance.

Made by additive manufacturing (AM) technology using a patented material with a low environmental footprint, WSM-170 is ideal for composites processing including autoclave and out-of-autoclave (OOA) methods such as resin transfer molding (RTM) with an external counter-mold.

The carbon exoskeleton technology from Addyx can produce molded ribs, in this case, inside a carbon fiber-reinforced polymer (CFRP) composite tube. Photo Credit: Addyx

Ultimately, Addyx aims to change the paradigm for the topology optimization of composite structures and enable more efficient design, manufacturing and structural performance.

Advantages for the resulting composite components include:

- Up to 40% reduction in manufacturing time.

- Up to 15% reduction in scrap rate.

- Up to 20% weight reduction.

- High-quality surface finish on external and internal surfaces.

- Sustainability — mandrel wash out using tap water.

For more details, visit Addyx at the JEC World 2023 event (April 25-27, Paris, France) in the Startup Booster Village (Booth H4, Hall 6).

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.