Plant tour: ATK Aerospace Structures, Clearfield, Utah, U.S.

High-volume, high-precision fiber and tape placement for the aerospace industry are among many specialties for this composites manufacturing behemoth.

Editor’s note: Subsequent to the publication of this plant tour, ATK was acquired by Orbital and became Orbital ATK. Orbital ATK was then acquired by Northrop Grumman, which is the current owner and operator of the Clearfield, Utah, facility.

ATK Aerospace Structures literally grew up with the composites industry. In the 1950s, the company was established to filament wind rocket motor cases for the U.S. defense and space programs. Today, it’s difficult to find an aerocomposites program in which the company does not or did not have its hand: Current commercial aircraft programs include the Boeing 787 and Airbus A350 XWB as well as the General Electric GEnx 2B and Rolls-Royce Trent XWB jet engines. Military aircraft include the Airbus A400M and Boeing’s C-17 Globemaster transports, Lockheed Martin’s F-22 Raptor and F-35 Lightning II fighter aircraft and AgustaWestland’s 609 helicopter. Space systems have included the Delta IV and Atlas V launch vehicles and the International Space Station (ISS).

Spread out over three US states, ATK Aerospace Structures now maintains manufacturing facilities in Dayton, OH; Iuka, MS; and Clearfield, UT. The Clearfield installation is in an industrial park about an hour north of Salt Lake City. It occupies the site of what was, during World War II, an inland US Navy installation deemed beyond the reach of Japanese aircraft that might accost the US from the Pacific Ocean off the California coast. There, a collection of long, but undistinguished buildings that are now home to ATK betray little from the outside about the substantial activity inside. The Clearfield facility houses three primary activities: Aircraft Commercial (57,000m2, 17% cleanroom), Military Structures (60,000m2, 12% cleanroom) and Case Manufacturing (18,000m2). Clearfield employs 800 people, and the Aerospace Structures division as a whole employs 1,000 people in total.

When CW was offered the opportunity to tour Clearfield operations, the firm’s largest facility, the door was open to document how the company built on its filament-winding legacy to become one of the aerocomposites sector’s leading innovators and one of the most aggressive, disciplined and experienced high-performance composites fabricators in the world.

CW’s guide through the Clearfield facility was Barrett Milenski, R&D engineer and 9-year employee of ATK. Although Clearfield still produces rocket motor cases and mints a long list of other structures — engine cases, nacelles, fuselage components, door springs, pivot shafts, wingskins, wing cover stringers, fixed skins and pressure vessels — the tour’s first stop put the spotlight on two recently developed product types that dominate production in terms of numbers and illustrate ATK’s enduring commitment to pushing the limits of technology.

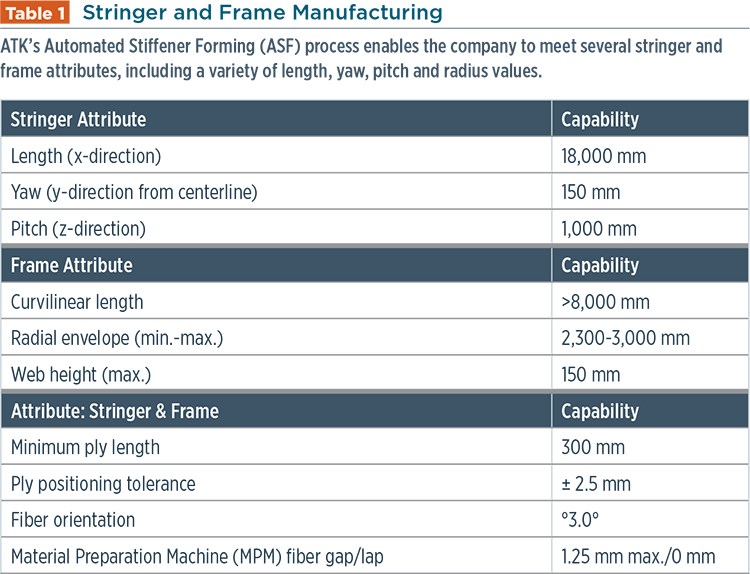

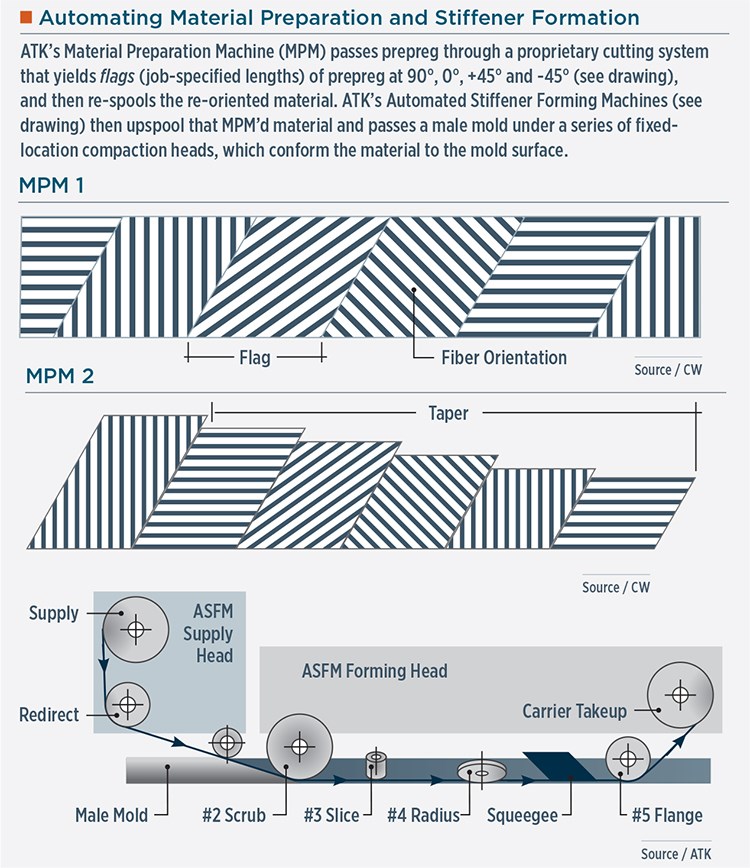

Stringers and frames

Clearfield manufactures fuselage stringers and frames for the Airbus A350-900 and A350-1000 and the center and aft fuselage frames for the Boeing 787-9 and 787-10. Milenski pointed out that manufacture of these complex parts is among the most challenging enterprises ATK has faced. The stringers and frames for the A350-900 alone involve 698 different part numbers, and a single shipset constitutes 900 components. Since A350-900 production began, ATK has delivered more than 30,000 stringers and frames for the aircraft. Although automated tape placement technologies have matured significantly in recent years, matching such volumes with off-the-shelf technology was not possible. The company employs, instead, two in-house-developed technologies that combine unique fiber preparation with a high-volume process that enables ATK to hit the A350’s production targets and give ATK, in this arena, a real competitive advantage. The first is the aptly named Material Preparation Machine (MPM), a continuous process that does just that. The machine accepts up to 600m long rolls of 600-mm wide unidirectional (UD) HexPly carbon fiber prepreg tape supplied by Hexcel (Stamford, CT, US), unrolls it, and passes the prepreg through a proprietary cutting system. The cutter yields flags — the term for job-specified lengths — of prepreg at biases of 90°, 0°, +45° and -45°. The system then re-orients each flag to a pre-programmed angle, puts it back in line with other flags, and re-spools the re-oriented material (see drawing at left). The material is then slit and re-spooled to one of several widths used at the plant. The new prepreg roll comprises a series of UD flags oriented at a variety of angles that meet specific load requirements of particular stringers and frames (see Table 1, at left).

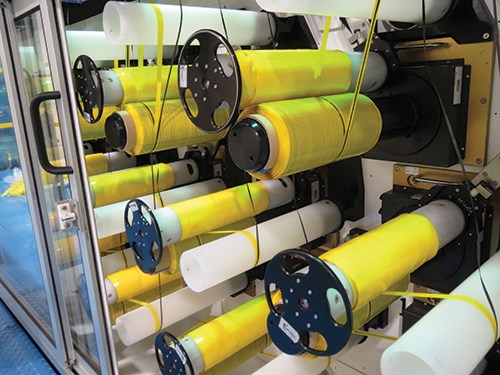

After it leaves the MPM, each roll is delivered to a cleanroom in the Clearfield plant called the Aircraft Commercial Center of Excellence (ACCE), where it is loaded onto one of five Automated Stiffener Forming Machines (ASFM) — ASFM-L0401, ASFM-L0402, ASFM-L0501, ASFM-R0201 and ASFM-R0202. Machines designated with an “-L” are used to manufacture linear parts such as stringers. Machines designated with a “-R” are radial machines that manufacture frames. With this second in-house technology, ATK has fully automated stringer and frame manufacture. The principle of ASFM operation is relatively simple yet the machine is fast: A male mold, for a C-, Z-, or I-beam or hat cross-section, is passed under a series of fixed-location compaction heads, which push the MPM’d material onto the tool surface, conforming it to the wide variety of shapes, angles and dimensions presented by stringer molds. ASFM-L0401 and ASFM-L0402 each have four heads to provide scrub, side, radius and flange compaction operations (see illustration, at left).

“ASFM-L calls it pitch, roll and yaw,” says Milenski, referring to the myriad of tool types that must be accommodated by an ASFM. “Each tool has its own swoop, twist or curve, and the ASFM has to be able to put down material for each one.” The ASFMs not only lay down prepreg with precision, but can build a laminate up to 66 plies thick, and can do so 10 times faster than is possible with manual processes. Further, says Milenski, ASFM processing requires no intermediate debulks. On average, stringers up to 18m in length can be laminated, formed, bagged and ready for cure in approximately 2 hours.

Although stringers present daunting variation, Milenski says the most complex aspect of the ASFM process is mold manufacture and management. Each of the 698 stringers and frames on the A350-900 requires a unique Invar mold. Each tool, Milenski notes, has a carbon fiber caul, and most of the molds are of the Omega-shape type. Each mold is affixed with a radio frequency identification (RFID) tag that identifies the tool’s location in the plant. In the future, the RFID tags will be integrated into the lamination process to identify the part and signal to the ASFM where and how prepreg should be applied.

“These molds are incredibly important to us and our customers,” Milenski points out. Hundreds of tools are stored horizontally on tall racks just outside the ASFM fabrication room. Locating a stringer on the rack, moving it, loading it in the ASFM and then returning to its rack is, in itself, a full time job in Clearfield. “Managing and maintaining them properly is a big part of what we do.”

After each ply layup, a mold is robotically pushed out from under the ASFM compaction heads. Off the end of the layup bed is a Virtek Vision International Inc. (Waterloo, ON, Canada) laser projection system that is used to verify proper ply placement and check for foreign object damage (FOD). Layups that pass this test are bagged and prepared for autoclave cure. Once bagged, the parts pass through a cut in the cleanroom wall to the cure staging area.

Up to this point, mold manipulation has been accomplished primarily with forklifts and robots, but getting a mold into the autoclave is a manual process, yet one ATK has simplified with a bit of creative thinking. A bagged mold is loaded onto a tool transfer cart, about 500 mm wide and 900 mm tall. A metallic mold on such a cart might normally be moved by crane, tug or forklift, but at ATK it’s done over a large floor — spanning the space from the ASFM cleanroom to the autoclaves — embedded at regular intervals with small roller balls (see photo, at left). The transfer carts, pushed by one or two ATK employees, as needed, move easily over the roller balls for quick delivery to the autoclave.

ATK has three autoclaves, all supplied by ASC Process Systems(Valencia, CA, US). Two are 18.3m long and the third is 26m long. Three more are expected soon, and will accommodate manufacture of stringers and frames for the A350-1000. Each autoclave, says Milenski, can accommodate 40-45 stringer molds.

Frame manufacturing at ATK operates on principles similar to those that drive stringer fabrication, but a frame’s curved z-shape introduces some new complexities. Also developed in-house, ATK’s ASF framemaking machine, designated ASFM-R, is oriented around a donut-shaped steel rotary table that rests horizontally on the shop floor. Over the table is a large blue gantry, on which are interchangeable tape-laying heads and a forming station. The tape heads are exchanged on the ATK gantry by a robot from Kuka Robotics Corp. (Shelby Township, MI, US). An RFID-tagged frame mold is secured to the table, which then rotates to the tape-laying station, where Hexcel carbon fiber prepreg tape is placed by the ATK gantry. The robot chooses tapes from several feed heads loaded onto the gantry, applying tapes of varying widths and orientations, depending on the tool type. When the layup is complete, the table indexes to the forming station, where tapes are compacted.

For some frames, says Milenski, 0° plies are preformed separately on a cutting table and then placed in the tool by hand before automated tape placement begins. These rainbows, as they’re called, are formed using an Electroimpact Inc. (Mukilteo, WA, US) automated fiber placement (AFP) machine outfitted with a head that can simultaneously place up to 16 6.4-mm wide tows. The AFP, says Milenski, “places the rainbows and then cuts a border around them with an ultrasonic knife.” The vacuum table, also made by Electroimpact, features a zoned vacuum system, which holds the rainbows in place during layup. Each rainbow preform is only one ply thick; each frame requires between 12 and 36 of these 0° plies.

Nondestructive inspection (NDI) of all stringers and frames is done on an ATK-designed and -built phased array system. The company also uses a proprietary linear NDI system.

High-performance AFP

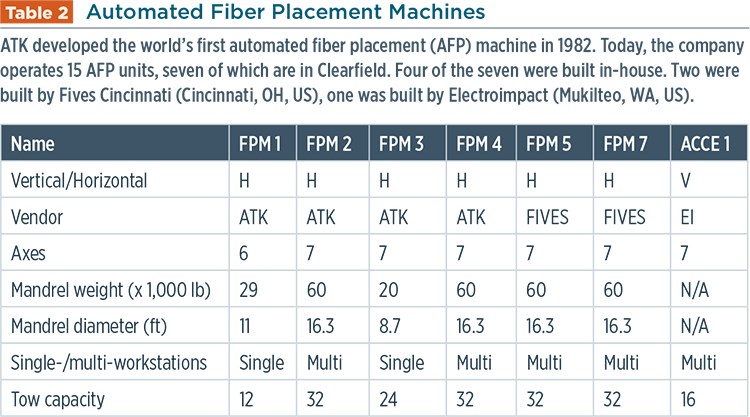

As the tour moved on, it became abundantly clear the MPM and ASFM are simply the latest in an impressive series of technology adaptations behind ATK’s success. Second only to stringer and frame activities, ATK’s most active manufacturing process in Clearfield focuses on automated fiber placement (AFP). And it’s no wonder: ATK developed the first AFP process in 1982, and has been fine-tuning it since.

As an AFP pioneer, ATK maintains several AFP machines that were developed in-house. In Clearfield, four of its seven AFP machines are ATK-made, two others were built by Fives Cincinnati (Hebron, KY, US) and one more was supplied by Electroimpact (see Table 2, at left). The latter, noted earlier, is used to make arched stack-ups for fuselage frames. Across all US locations, ATK operates 15 AFP machines — five built in-house, one from Electroimpact and nine others from Fives Cincinnati.

The largest AFP parts manufactured in Clearfield are the carbon fiber/BMI wingskins for the F-35 Lightning II. Fiber placement machine (FPM) 2, as it’s called, is used for the job and features a 27,216-kg multi-station mandrel and a 32-tow head with seven axes of motion. The “multi” designation accounts for what happens after a wingskin has been fully placed: The mandrel automatically rotates on a horizontal axis away from the machine head to be scanned by a Virtek laser projector system, which verifies the accuracy of dimensions, fiber orientation and ply boundaries, and checks for gaps and FOD.

Milenski says the BMI, supplied by Cytec Aerospace Materials (Tempe, AZ, US), has proven particularly challenging to fiber place because of its low tack: “In my opinion, the F-35 nacelle is one of the hardest parts to fiber place that I know of.” All the same, ATK has gotten pretty good at it. “Making a BMI ply at over 1,000 inches per minute this pretty?” says Milenski, pointing to a skin undergoing laser inspection. “I cannot reiterate how hard that is.”

One reason for the difficulty, Milenski notes, is the OEM’s strict skin thickness requirements. This entails frequent measurement of tools and laminates, and the presence of operators on the shop floor who, Milenski says, “are trained to verify quality.” Ideally, a skin comes out of the autoclave within thickness tolerances, but if it doesn’t, ATK must build up or machine away material.

During CW’s visit, ATK was in the process of completing buy-off of a new Fives VIPER AFP machine, designated FPM 5, that will work in tandem with another VIPER to make F-35 wingskins. The new VIPER features an operator platform equipped with a carbon fiber creel bank that feeds the placement head. The entire platform, with operator, “rides” with the placement head as it works on a mold. Milenski says the machine’s laydown rate is 35.6 m/min, which he characterized as “a very big deal for BMI.”

ATK’s relationship with Fives, says Milenski, is one of close collaboration. So close in fact, that ATK was the first to use Fives’ Dockable Gantry System (DGS), which combines ATL and AFP in one machine. The gantry-based unit’s ATL head handles the large, noncomplex surfaces, and then — on the same mold — the machine’s control system can switch, automatically, to an AFP head for narrow, more complex and/or highly contoured surfaces. The head-to-head transition takes less than 2 minutes. For that reason, the system is expected to optimize material deposition rates and increase manufacturing flexibility.

Back to the future

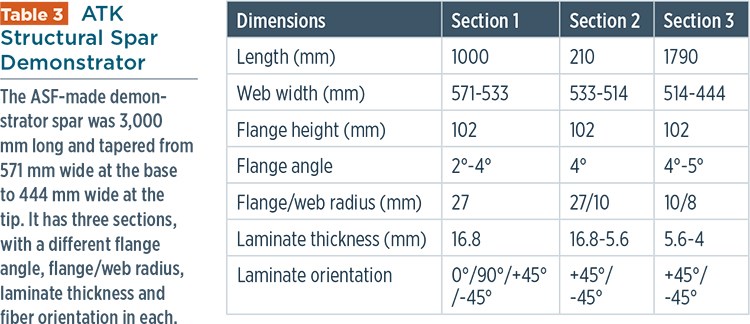

Although ATK has honed its fiber placement, tape laying and automation expertise to new highs for speed and precision, ATK continues to invest substantially in R&D, and isn’t letting its past dictate its future. Notable on the horizon is its Automated Spar Forming (ASF) technology, which will compete with the ATL, AFP and hot-drape forming technologies used today to manufacture spars. ASF dispenses carbon fiber prepreg tapes into a female spar tool from one of four in-line rolls positioned over the tool. As tapes are laid, a series of rollers passes over the tool surface, providing compaction and debulk operations, working horizontal and vertical tool surfaces. The system can accommodate thickness changes across a spar and automates tapered joggles with ply drops. The benefits, says ATK, are reduced handling risk, good fiber alignment, consistent and tight radii, low void content, elimination of intermediate debulks, increased design flexibility and reduced material buy-to-fly ratio. A spar demonstrator manufactured by ATK shows the system’s capabilities to meet a variety of flange angles, radiuses, thicknesses and fiber angles (see Table 3, at left).

ATK also is pursuing out-of-autoclave (OOA) technology with its Ultrasonic Tape Lamination (UTL) system, which features ATL placement of thermoset- or thermoplastic-based prepreg tape (the former is cured in-situ, ultrasonically, at the tape head). ATK has demonstrated the process with prepregs from a variety of US suppliers, including Cytec’s Cycom 977-2, HexPly 8552 and HexPly M21E from Hexcel and PEEK from an unidentified supplier. A cryogenic tank recently made with Cycom 977-2 epoxy had resin volume of 36.8% (vs. 37.2% for autoclave), fiber volume of 62.76% (vs. 62.8%) and void volume of 0.425% (vs. 0.006%).

Also coming soon, ATK will roll out the MPM2, its next-generation Material Preparation Machine. ATK has partnered with MTorres (Pamplona, Spain) on this new machine. MPM2 will provide two new options: production of material up to 1.5m wide; and tapering of flag width to optimize material use, especially in spar fabrication applications (see MPM1 and MPM2 flag comparisons, at left.)

ATK’s already-rich technological history and future promise that this firm will remain in the vanguard of composites evolution. As it seeks new ways to automate and streamline fabrication processes, the composites industry — particularly its aerocomposites arm — will continue to look to leaders who, like ATK, seek increasing sophistication in process integration and quality control at production rates unlike any the industry has seen. Milenski concludes: “ATK believes that continuing to develop new, high-volume automated composites manufacturing processes is the key to expanding the use of composites on aerospace structures while maintaining high-tech jobs in the US.”

Orbital ATK Aerospace Structures

Related Content

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreAirbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

BMW Leipzig: The epicenter of i3 production

A glimpse into the inner workings of an automaker at the forefront of serial-production autocomposites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More