Automotive composites draw international crowd to Detroit

19th SPE ACCE features broad technology overview of evolving automotive composites industry.

Cynthia Flanigan, chief engineer of Vehicle Research & Technology for Ford Motor Co. delivers the opening keynote at SPE ACCE 2019. Photo | Mark Richardson, Society of Plastics Engineers

From September 4 through 6, 2019, just under 900 people attended the 19th-annual Automotive Composites Conference & Exhibition (ACCE) organized by the Automotive and Composites Divisions of the Society of Plastics Engineers (SPE, Bethel, Conn., U.S.). Held in the Detroit suburbs, the event featured four parallel technical tracks all three days, three keynotes, two panel discussions, two evening receptions, and an exhibition. A large student poster competition and a parts competition rounded out the program.

This year’s event was smaller — in terms of attendance, presentations and sponsorship — than it’s been the last few years. Organizers cited a direct conflict with the China Composites Expo (September 3-5 in Shanghai, China) as well as events like the triennial Kunststoffe (K 2019) plastics show in Düsseldorf, Germany, October 16-23 and earlier dates for the annual Composites and Advanced Materials Expo (CAMX), co-organized by the American Composites Manufacturers Assoc. (ACMA, Arlington, Va., U.S.) and Society for the Advancement of Materials and Process Engineering (SAMPE, Diamond Bar, Calif., U.S.) in Anaheim, Calif., September 23-26 as impacting participation. Nonetheless, the event drew thought-provoking presentations, interesting technologies, and an engaged international audience.

The technical program’s 87 talks covered thermoplastic composites, thermoset composites, carbon composites, enabling technologies (process/equipment), additive manufacturing/3D printing, sustainable composites, bonding/joining/finishing, reinforcements, business trends & technology solutions, and virtual prototyping/testing/modeling. With so much content, what follows is necessarily a narrow slice of all the innovation seen and discussed.

Materials innovation

The growing popularity of composite liftgates makes a new primerless structural adhesive developed by Ashland LLC (Covington, Ky., U.S.) timely. Formulated for low-modulus/high-elongation properties, it’s said to be ideal for handling coefficient of linear thermal expansion (CLTE) mismatches in hybrid-material systems, such as bonded liftgate panels. The adhesive was specifically formulated for low-surface-energy olefin substrates — e.g. long-fiber polypropylene structural/inner panels and thermoplastic polyolefin Class A skins/exterior panels. Olefins’ non-polar nature make them notoriously difficult to bond. The product, which still is considered developmental and won’t be commercially available for 3-6 months, is called Pliogrip 200LM and is based on polyurethane chemistry.

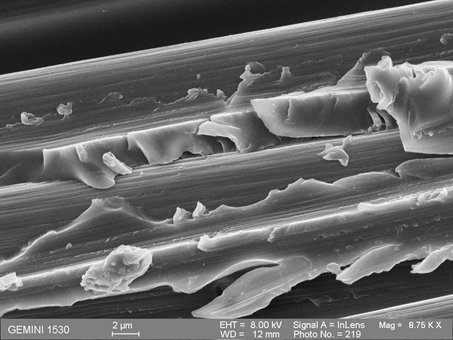

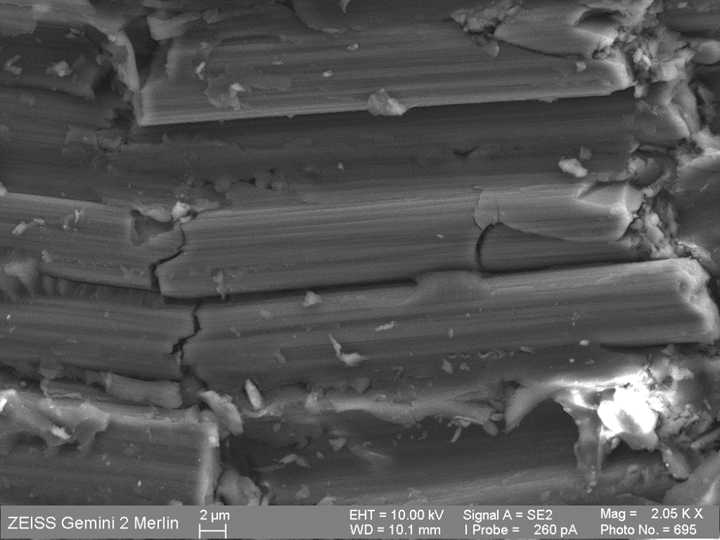

A new solvent-free coupling agent called BYK-C 8013 that increases mechanical performance of carbon fiber/vinyl ester or unsaturated polyester composites was described by a speaker from BYK USA Inc. (Wallingford, Ct., U.S.). This versatile liquid chemistry can be applied directly to fibers via sizing bath, sprayed on fabrics as a “second” sizing, or directly incorporated into resin matrices prior to impregnation. Mechanical performance increases of up to 70% have been demonstrated. Scanning-electron micrographs (SEMs) confirm the strength of the resin/fiber bond.

A new coupling agent from BYK USA Inc. for radical-cure carbon fiber-reinforced composites (e.g. with vinyl ester or unsaturated polyester matrices) has demonstrated mechanical performance increases of up to 70% and SEMs, like those above, demonstrate the strength of the fiber/resin bond. | BYK USA Inc.

Process/equipment enhancements

Fraunhofer Institute for Chemical Technology (F-ICT, Pfinztal, Germany) was back with a report on a multi-year/multi-partner consortium that developed the MoPaHyb modular production plant for hybrid (all-composites or metal/composite) components at high throughputs and relatively low piece costs. The entire “plant” can be reconfigured repeatedly to switch production between different types of thermoset and thermoplastic composites. All equipment is designed to be ‘plug-’n-play’ and to connect to a base control unit. The AML engineering language and OPC UA communications interface standardize machine communications. This production concept was validated using several different types of demonstrator parts. F-ICT notes that the entire plant or individual plant configurations and machines are available for customer trials and prototype manufacturing.

A multi-year/multi-partner German consortium has developed the MoPaHyb modular production plant for hybrid (all-composites or metal/composite) components at high throughputs and relatively low piece costs. The entire “plant” can be reconfigured repeatedly to switch production between different types of thermoset and thermoplastic composites. This production concept was validated using several different types of demonstrator parts. | Fraunhofer Institute for Chemical Technology

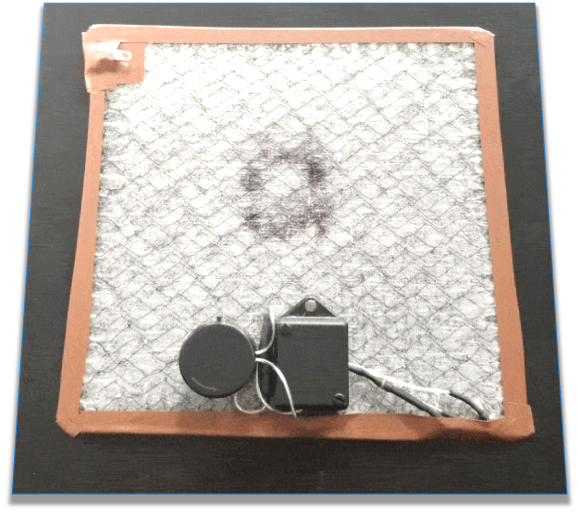

Process innovation also was front and center during two presentations by the Performance Materials division of Coats Group PLC (Uxbridge, U.K.). The 250+-year-old industrial thread and synthetic fiber manufacturer, whose products are widely used in automotive, has recently ventured into composites with the development of its Synergex commingling and Lattice fiber-laying (and stitching) technologies to produce near-net shape thermoplastic or thermoset preforms. The technology, which Coats calls “automated additive manufacturing,” is designed to improve laminate layup quality and repeatability/reproducibility (R&R), reduce waste and labor costs, and lower part mass via fiber optimization. Consistent fiber fractions are achieved by controlling denier of fiber inputs. Surprisingly, given the sophisticated preforms that can be created, costs are said to be lower and performance higher vs. preforms from conventional laminate processes for comparable resin/reinforcement configurations.

Coats Group PLC has developed its Lattice fiber-laying (and stitching) technology to produce near-net shape thermoplastic or thermoset preforms. Given the sophisticated preforms that can be created, surprisingly costs are said to be lower and performance higher than preforms from conventional laminate processes using comparable resin/reinforcement configurations. | Coats Group PLC

The versatile Lattice process can produce preforms using a wide variety of fibers and matrices – including those with conductive pathways. | Coats Group PLC

An interesting equipment innovation involved an automated cutting and stacking cell for dry-fiber textile reinforcements. Developed by equipment OEM Schmidt & Heinzmann GmbH & Co. KG (Bruchsal, Germany), the system is designed to cut and stack 15+ plies of glass or carbon fiber-based textiles, non-wovens, preconsolidated layups, prepregs, honeycomb, foam sheets or even metal-mesh sheets quickly and precisely, then label the stacks and spot-weld layers to keep them from shifting prior to processing via resin-transfer molding (RTM) or wet-compression molding. Interchangeable cutters, universal gripper systems and sophisticated material-position sensors help ensure material is processed accurately and quickly, while adaptive nesting algorithms help maximize material usage and reduce scrap. There is even virtual process-startup and commissioning software to help debug the line before it’s even built so it operates without problems when actually installed.

Reinforcement and repair

In the cool-but-not-yet-commercial category, Old Dominion University (Norfolk, Va., U.S.) presented new research (partially supported by the Jeffress Trust Awards Program in Interdisciplinary Research (Boston, Mass., U.S.) on a method for through-thickness reinforcement (TTR) and repair of carbon fiber/epoxy sandwich panel composites. The technique involves first micro-drilling tiny holes through the panel’s carbon fabric skins and into its aramid honeycomb core. Next, submillimeter pultruded carbon fiber/vinyl ester rods/pins, often used by crafters, are inserted into the sandwich’s Z-axis. Last, low-viscosity epoxy resin is injected to seal the rods in place. Rigorous testing showed that the load-carrying capability of failed sandwich composites with significant delamination or disbond damage was restored to values at or above benchmark/pristine samples via the TTR technique. There even was a marginal increase noted on pristine samples that were not subsequently damaged prior to using TTR. More work is needed, but the research is intriguing and could eventually lead to a non-destructive repair technique.

An interesting research project by Old Dominion University (Norfolk, Va., U.S.) involved developing a method for through-thickness reinforcement (TTR) and repair of sandwich composites. After drilling micro-holes through a damaged panel’s skins and into its core, researchers inserted submillimeter pultruded composite rods/pins into the composite’s Z-axis, then injected low-viscosity resin to seal rods in place. | Old Dominion University

Rigorous testing showed that the load-carrying capability of failed sandwich composites with significant delamination or disbond damage was restored to values at or above benchmark/pristine samples via the TTR technique. More work is needed, but the research is intriguing and could eventually lead to a non-destructive repair technique. | Old Dominion University

One of the last sessions in the conference featured four back-to-back talks with final lessons learned on the multi-year, innovative carbon fiber-reinforced SMC engine subframe research project between Ford Motor Co. (Dearborn, Mich., U.S.) and Magna Exteriors (Troy, Mich., U.S.) that concluded earlier this year. (To learn more about the collaboration read “Teaming to define what automotive CFRP could be” by Ginger Gardiner).

The 20th SPE ACCE will return September 9-11, 2020.

Related Content

SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Can the automotive industry turn to face the change?

SPE ACCE speakers speculate about how changing consumer behaviors might shape the automotive industry.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;width=70;height=70;mode=crop)