Clean Sky project targets multifunctional composites for electric aircraft

All-electric commercial aircraft will require a lot of power. Multifunctional composite structures might provide a power-storage medium.

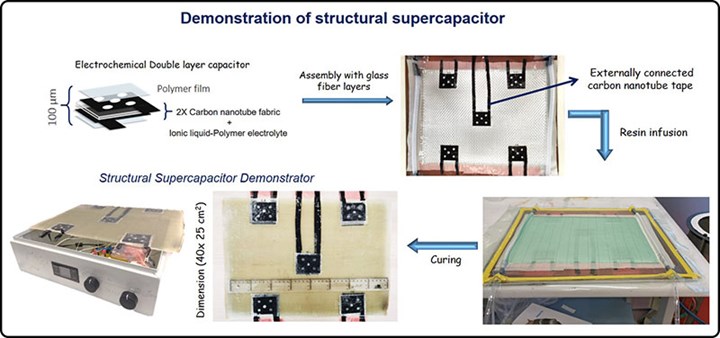

Illustration of a structural supercapacitor developed in SORCERER. Source | Clean Sky

European aerospace R&D consortium Clean Sky provided on April 2 an update on its SORCERER (Structural pOweR CompositEs foR futurE civil aiRcraft) project, which is designed to assess integration of electrical systems within a composite laminate.

The project, which started in 2017 and runs until July 2020 with a budget of €1.6 million, explores the potential for combining electrical energy storage in aircraft composites to form elements of the aircraft structure. SORCERER contributes to Clean Sky’s Multifunctional Fuselage Demonstrator program, which focuses on validating high-potential combinations of airframe, cabin, cargo and system elements, making extensive use of thermoplastic composites, looking at how to pre-equip, or make use of, multipurpose systems and materials.

“This project is also an enabler for future electrical and hybrid-electric propulsion aircraft,” says Clean Sky 2 project officer Jimmy Tchen. “In terms of energy storage, there’s a big challenge. The traditional way to minimize the mass of energy storage components has been to try to increase the power density of the batteries. SORCERER’s approach is to develop multifunctional material which could combine structural and energy storage functions, providing weight and volume reductions.”

The project, which is funded in part by the EU’s prestigious Horizon 2020 program, is undertaken by a consortium led by Imperial College London (ICL) and supported by Chalmers University of Technology in Gothenburg; the Royal Institute of Technology (KTH) in Stockholm; and IMDEA Materials Institute in Madrid. The workload is divided into three interconnected streams.

For the structural supercapacitors, the SORCERER team plans to manufacture an aircraft door-frame beam, a structural part with embedded structural supercapacitors.

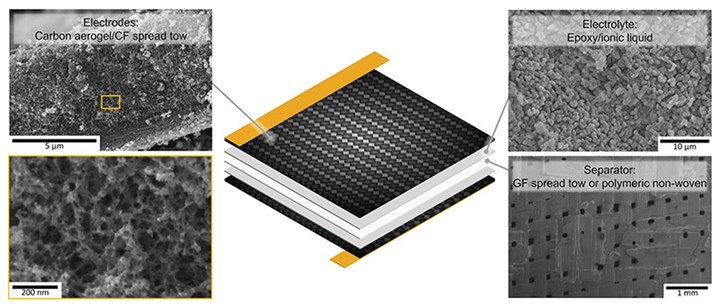

Firstly, Imperial College is exploring the critical issues associated with structural supercapacitors and their adoption into aerospace platforms. This means confronting the issues associated with improved power and energy densities, encapsulation and laminate hybridization, and multifunctional design methodologies.

The project’s second stream focuses on technical issues associated with structural batteries, an activity led by Chalmers University. Here, the materials proposed will be evaluated with respect to their future aircraft operational conditions.

Thirdly, there is a stream of activity related to structural energy generation using ionintercalated carbon fibers, and energy harvesting solutions, led by KTH. Here the focus is on enhancing efficiency and power output, with the aim of progressing this technology towards Technology Readiness Level (TRL) 3.

Regarding the state of progress, Clean Sky’s Tchen says, “In terms of TRL maturity, the structural supercapacitor is at a more mature level than the two other technologies. At the lowest maturity, energy harvesting. This will be a lab scale demo. And for the structural batteries they’re looking at a full size demonstrator.”

Demonstrator of structural supercapacitor made by project partner IMDEA. Source | Clean Sky

For the structural supercapacitors, the SORCERER team plans to manufacture an aircraft door-frame beam, a structural part with embedded structural supercapacitors. This, however, has prompted an additional question: If an aircraft structure is also effectively a form of battery, does that mean that the airframe will have a limited life in terms of its ability to store energy?

“Yes, that is a potential issue, as it would be with batteries,” says Professor Emile Greenhalgh, Professor of Composite Materials and head of the Composites Centre at Imperial College London, who leads the SORCERER project. “But the technologies we are developing are covering a range of power sources, not just batteries. For instance, the work at ICL is focused on supercapacitors, which don’t store as much energy, but have much better longevity.”

Although SORCERER is an important step towards making electric aviation a reality, Clean Sky says there is still a ways to go.

“This is not embedding batteries, but producing a material which intrinsically can undertake dual roles,” Greenhalgh adds. “This builds on world-leading knowledge and capabilities which have been developed in the UK and Spain (structural supercapacitors) and Sweden (structural batteries) over the last decade, and on learnings from a successful forerunner of this project, STORAGE, funded by an earlier EU research funding scheme. This project enables full electrification of future air transport, which is an aspiration of organizations such as Airbus, who wish to have a fully electric 100-seat aircraft by 2050.”

Although SORCERER is an important step towards making electric aviation a reality, Clean Sky says there is still a ways to go. If conventional batteries were adopted for a 100-seat aircraft, the performance of the batteries would need to exceed the current state of the art by a factor of at least 10. This would mean adoption of exotic but immature battery chemistries. It would also mean aircraft carrying very highly concentrated sources of energy — at energy densities akin to that of explosives — so this approach has safety issues that would require extensive research and testing.

“Our alternative approach means the concentration of energy needed would be much lower, and hence would negate the same safety issues,” says Greenhalgh. “It would also mean an overall reduction in aircraft weight, offering savings regarding environmental impact. Europe is currently world leading in this field, although China, Korea and the U.S. are putting a lot of resources in this area. If we keep this technology in Europe, it will mean Europe will be best placed to deliver the first fully electric passenger airliner.”

Related Content

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More