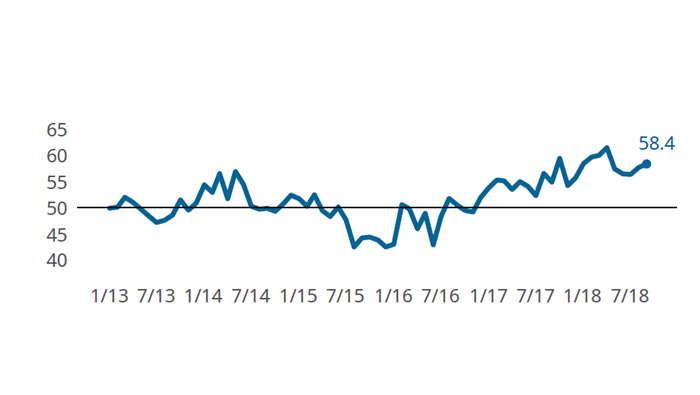

Composites Index Expands into Rarely Seen Territory

The GBI: Composites Fabricating Index expanded to a 58.4 reading in September.

The GBI: Composites Fabricating Index extended its latest expansion run into rarely reached territory with a reading of 58.4 in September. The latest reading marks the third time in the Index’s history during which the index has been on an upward trajectory that took it above a reading of 57. The latest reading is 6.0% higher than it was during the same month one year ago. Gardner Intelligence’s review of the underlying data for the month indicates that the Index was pulled higher by supplier deliveries, backlog, production and new orders. The Index — calculated as an average — was pulled lower by employment and exports. Among all components, backlogs expanded faster than all other components except for supplier deliveries.

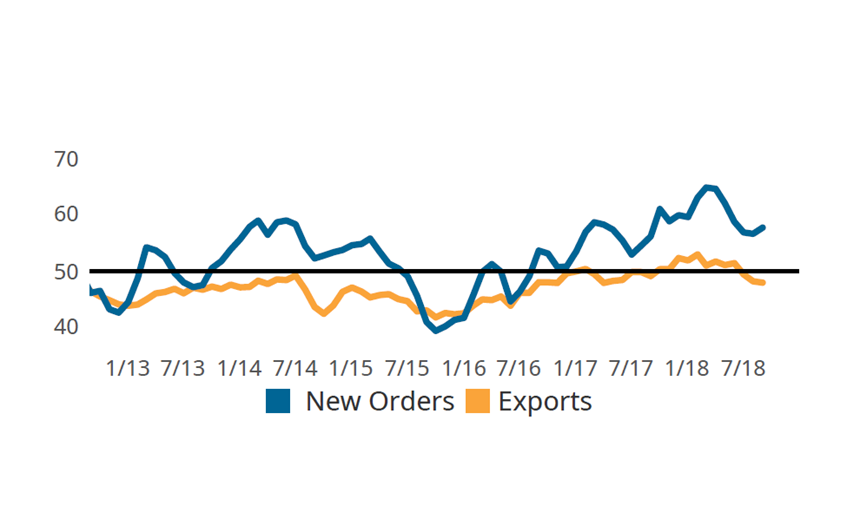

After new orders expansion peaked in March of this year, supplier deliveries and production were regularly the two fastest-expanding components of the Composites Index. At the same time, new orders expansion fell, indicating only that the monthly rate of growth of new orders was slowing. Since July’s new order reading, however, new orders growth has rebounded. This is despite the fact that exports have contracted since June of this year. The net effect appears to suggest that while export demand has slowed in the composites space during the second quarter of the year and early in the third, total demand for composites manufacturing is doing very well. New orders since mid-2015 have continued to cyclically improve.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

.jpg;width=70;height=70;mode=crop)