Composites Oust Magnesium In Big Volume Engine

DaimlerChrysler shaves part cost, investment and time to market in replacing magnesium valve covers with vinyl ester BMC.

In the design and approval of a critical engine component, the automotive engineer concentrates first on performance and reliability, then balances the material and process decisions with economics. Engines today incorporate a host of improved technologies, designed to ensure high reliability and minimal maintenance costs. One material gaining acceptance in engine components is cast magnesium. With its 1.8 g/cc density (about two-thirds that of aluminum) and favorable property profile, magnesium was initially specified, over steel and plastic, for the left and right valve covers of DaimlerChrysler's (Auburn Hills, Mich., U.S.A.) redesigned 4.7L V-8 engine, introduced in 1999. Built in volumes of approximately 500,000 per year, the engine is common to several platforms, including the Dodge Durango, RAM and Dakota trucks, and the Jeep Grand Cherokee.

In late 2001, DaimlerChrysler saw an opportunity to convert the valve covers to glass-reinforced BMC and, in so doing, save a lot of money in purchased part costs. Demand and other factors have driven up the cost of magnesium substantially, and the process used to make the covers involved a number of expensive secondary operations not required with vinyl ester BMC valve covers. The company already used BMC in valve covers for its 2.7L and 2.0L engines, so the performance was well-established. By some estimates, over 50 million BMC and SMC valve covers have been produced since 1988 without a single field failure, confirming the material's long-term reliability.

Key to gaining approval to proceed, emphasizes Steve Crawford, design release engineer for DaimlerChrysler, was that desired reduction in cure time and material costs could only be achieved if the wall thickness of the composite covers could be reduced to about 2.5 mm (0.100 inch), from the then-current standard of 3.5 to 4.0 mm (0.140 to 0.160 inch). In addition, the project needed to be completed quickly, which limited any prototype effort. Given these constraints, the conversion relied extensively on computer simulation and parallel analysis and validation efforts, resulting in project launch to full production in only eleven months — a dramatic reduction compared to the typical three-year development cycle.

Computer simulation provides confidence in design

The computer analysis involved simulation of the mold filling and resulting fiber orientation, followed by structural and vibration modeling. Due to the layout of the cylinders, the 4.7L engine develops considerable heat, and the valve cover temperature can reach as high as 204°C (400°F), and both thermoplastic nylon 6/6 and thermoset materials were explored, Crawford says. For the composite covers, DaimlerChrysler selected Premi-Glas 1265, a glass-reinforced vinyl ester BMC from Premix Inc. (North Kingsville, Ohio, U.S.A.), due to its high temperature properties and approved use on the 2.0L engine, which is molded via injection-compression by Dana Corporation (Paris, Tenn., U.S.A.). In the injection-compression process, the mold is held slightly open during the injection of the material, then closed to achieve final shape. This reduces fiber damage but achieves properties slightly short of those possible with pure compression molding. However, for the 4.7L engine, Dana and DaimlerChrysler made the decision to mold the covers using straight injection molding, which would shorten the cycle time and make the parts easier to deflash. However, with the thinner wall, issues such as shear heating and complete mold filling would become even more critical and demand greater control over the process.

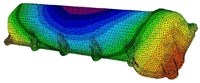

To gain initial confidence to go to injection molding, Dana modified the molding process for the 2.0L covers and produced a series of parts, which were quickly tested for performance and validated. Simultaneously, DaimlerChrysler turned to The Madison Group (Madison, Wis., U.S.A.) to simulate the mold filling of the 4.7L cover using its CADPRESS BMC software. While mold-filling software has existed for many years in thermoplastic injection, simulation of the thermoset injection process is further complicated by several factors, explains Dr. Paul Gramman, president of The Madison Group. "With thermosets, you have the combination of a very hot mold, a viscous skin layer of material, and a chemical reaction," he says. "In addition, the reinforcing fibers play an important role in determining how well the mold will fill, and whether knit lines will occur, creating potential weak points."

CADPRESS BMC was used to predict the filling of the part and the resulting fiber orientation. The injection simulation showed that slight "race tracking" would occur at the seal edge. Usually considered an undesirable effect in mold-filling operations, race tracking in this case would occur where the flow length was greatest, and therefore would actually assist in the mold filling process, enabling the BMC to flow from the injection gate up and over the top of the cover, without forming knit lines or trapping air. Dana and DaimlerChrysler conducted a series of "short shot" experiments performed on the actual mold, where less than the required quantity of material is injected and the resulting flow pattern observed empirically. A comparison of the predicted and observed results of the short shot experiments demonstrated a correlation to within approximately 2.5 mm (0.100 inch), notes Gramman.

The fiber orientation was shown to be the highest at the gate and in the last corners to fill, resulting in different property profiles in line with the fiber and transverse to it. The Madison Group provided the fiber orientation for each cell in the finite element model to Dana Corporation, who analyzed the structural performance of the part and completed vibration analysis, which predicted an improvement of 1 db, which was validated on molded valve covers. The area of higher fiber orientation were determined to be structurally sound, capable of handling the most extreme in serivce loads.

Crawford believes the simulation efforts were invaluable to meeting the performance goals and program timing. "Everything we analyzed came up clean," he emphasizes. "By using computer simulation, we eliminated the need for a prototype mold, which is two-thirds the cost of a production tool. In addition, if we prototyped the covers we would have done so in single-cavity molds, which wouldn't fill the same as dual-cavity molds."

Parallel work cuts time, cost

High-quality injection mold tooling is a long lead-time item, so shortly after project launch the mold-building process began while mold-fill simulations were still ongiong. To meet production requirements, two molds were constructed, each having two cavities of either the right-hand or left-hand valve cover. The chrome-plated, hardened D-2 steel molds were produced by Shaw Industries (Franklin, Pa., U.S.A.). The decision to go straight to production tooling was based on the risk reduction being provided by the computer analysis, and the magnitude of the economics provided by switching from magnesium sooner, rather than later. The decision turned out to be the right one — by the time the molds were nearing completion, only minor changes were required. For example, the finite element analysis resulted in the addition of gussets at some of the bolt areas, and the gate was modified from the original design to reduce molding stress, based on the results of the CADPRESS analysis.

Initial molding of the covers was completed on the molds prior to final surface finishing. In addition to the short shot analysis, enough parts were molded to install on test engines for dynamometer testing for hot, cold, and hot/cold cycle analysis. Valve covers were also put through vehicle tests at DaimlerChrysler's proving grounds and on taxi cabs, which accumulate a lot of miles quickly in stop and go conditions. Concurrent with the validation testing, the molds were textured to achieve a grained as-molded surface and the molds chromed. Stereolithography models were produced to verify that no changes would be necessary in existing returnable containers used to ship the covers to the engine assembly plant.

The Process Sign Off to approve the production process and tooling, including run-at-rate of 3,600 covers (1,800 engines) per day, was completed eleven months after the program launch, with full-volume ramp-up in approximately 15 months.

Savings open the hood for new applications

For the magnesium covers, the as-cast parts had to be moved to a separate area of the foundry for blasting with cut steel wire to achieve an aesthetically pleasing grained surface finish. The rubber seal gasket required an adhesive to hold it in place, which required a one- to two-hour cure, due to a shallow groove, which was difficult to control dimensionally, Crawford says. These steps, combined with inspection and leak testing resulted in a lot of in-process inventory.

By contrast, the BMC covers are transformed from raw compound to ready-for-shipping in under ten minutes. The parts have a textured surface right from the mold, are deflashed, cooled on a fixture and dimensionally checked right at the molding cell. A deeper, more controlled channel in the sealing edge permits immediate installation of a press-in-place gasket that requires no adhesive. The covers are leak checked with air pressure, marked with a serial number for tracking purposes, and put into the shipping container. The molding cycle for the covers is under one minute, resulting in a production rate of 500,000 covers per year from each of the two molding cells.

DaimlerChrysler's piece price savings amounted to $10 (USD) per engine, or about $5 million per year. In addition, while the magnesium molds have a life of 150,000 to 200,000 cycles, the BMC molds have an expected life of over 1 million cycles, resulting in lower mold costs over the life of the program. The faster molding cycle for the BMC parts, attained by going to straight injection and reducing the wall thickness, resulted in fewer molds (and injection presses) required to meet production rates.

Crawford believes the most significant outcomes of the metal-to-composite conversion, beyond the on-going cost savings, were the use of computer simulation to design the parts and the molding process, and the speed at which the changeover was accomplished. By April of 2004, DaimlerChrysler will put into production a BMC cover for a 3.7L V-6 engine, replacing stamped steel at a starting volume of 265,000 engines per year and growing, following the same methodology.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More