Converting the structural chassis to composites

Germany’s largest producer of GRP leaf springs for cars and trucks broadens its product range to CFRP stabilizer bars, which cut weight 50% vs. steel.

IFA Rotorion (Haldensleben, Germany) ranks among the world’s largest manufacturers of driveshafts. Founded in Haldensleben in 2005, its subsidiary, IFC Composite GmbH, now renamed IFA Composite, established a pedigree in a subset of the parent’s driveshaft specialty. Using high-strength, lightweight, fiber-reinforced composites instead of steel enabled IFA to integrate additional functions and reduce weight and part count. Three-piece driveshafts could shrink to two pieces, and two-piece driveshafts became single units.

The company uses filament winding, which enables efficient production of high-quality hollow parts and tubes in high volumes. Strands of dry carbon or glass fibers are wound around a reusable cylindrical or conical rotating core and then impregnated with resin. Thermoset or thermoplastic matrices can be employed, as well as prepreg tapes. With an estimated market of up to 300,000 composite tubes among Germany’s auto manufacturers alone, automation is now a must (see Fig. 1, at left). “The use of wound fiber composite materials in automotive is growing,” says Christian Schulz, the company’s head of composite structural parts at sister firm IFA Technology GmbH, which develops carbon composite parts. IFA Rotorion CEO Felix von Nathusius adds, “Cost-effective, large-series, lightweight parts will massively influence the future of vehicle design.”

Segue into suspension

IFA Composite also makes glass fiber-reinforced composite leaf springs. It began series production in 2006, making springs for the Mercedes-Benz Sprinter van, one of the most successful light commercial motor vehicles worldwide. IFA also produces composite leaf springs for Volkswagen and American Dodge. Most recently, the company has replaced steel in the leaf springs of heavy trucks of up to 40-ton capacity, saving as much as 400 kg in truck empty weight. This either reduces fuel consumption or is exchanged for increased load capacity (read more by clicking on the articles under under "Editor's Picks" at top right). As one of Germany’s largest composite leaf spring manufacturers, IFA has produced more than 1.3 million composite leaf springs, to date, with a Six Sigma quality measure of zero defects per million parts.

More recently, sister-firm IFA Technology developed and built the world’s first carbon fiber-reinforced plastic (CFRP) stabilizer bars in a production car, for the Volkswagen AG (Wolfsburg, Germany) XL1. The success of this metal-to-composite conversion has created a fourth strategic business for IFA Composite.

Stabilizer bar form and function

Automotive stabilizer bars, traditionally formed from steel, are a key component in many automobile suspension systems. Also called anti-roll bars, anti-sway bars or sway bars, they are used to reduce the body roll of a vehicle during fast cornering or when a wheel encounters irregularities on the road surface. Stabilizer bars also define a car’s oversteer or understeer characteristic — that is, its tendency to turn more or less than commanded, respectively. A stabilizer bar is situated between the left and right wheels, connecting them through short lever arms linked by a torsion spring. The bar is attached to the car chassis through rubber bushings. Stabilizer bars can be solid or hollow, and designed as monolithic — a single bar — or as a multi-component assembly, with separate lever arms.

“The discrete loading of a stabilizer bar — torsional load in the middle section and bending load in the lever arm — is an opportunity for composites’ tailorable anisotropy to provide a lightweight, efficient design,” explains Christian Schulz, head of composite structural parts at IFA Composite. Achieving not only a significant reduction in weight, but also a wider range of stiffness within the same outer shape, composites offered a solution, says Schulz, when requirements in the installation space could no longer be met using standard steel stabilizer bars. “Composite designs allow options which are harder to produce in steel.”

Process drives design

“As a high-volume manufacturer, streamlined production is the key for cost-effective parts,” says Schulz. R&D will always seek to make the parts lighter, he notes, “but optimal ‘rocket science’ designs could easily be too expensive for the added weight benefit.” The process IFA developed includes a preforming station, a molding press and a CNC machining center (see Fig. 2). Once the production process was set, Schulz says the steps were easily separated and simplified, so that parts could be fabricated in a smaller, limited-volume production environment, and then scaled up as necessary. “Currently, the parts are manufactured with limited machinery,” Schulz comments, “but the whole process can be readily scaled to semi-automated and then fully automated production.”

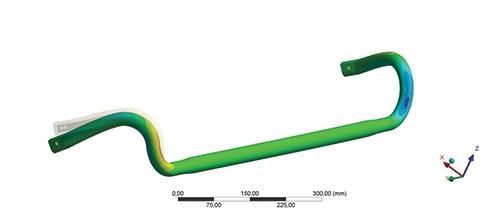

Next came refinement of the CFRP structural design, based on each program’s specific requirements. For example, the front and rear stabilizer bars for the XL1 are monolithic and hollow. Schulz explains that they are molded in a steel cavity tool, using a customized blow molding process, inner silicone bladder and air pressure. Because this molding system accommodates a wide range of laminate thicknesses, it enables nearly infinite stiffness variations within the same outer shape by varying the fiber layup. Each bar also varies in cross-sectional shape, having round as well as oval or even nearly square sections. “The path of the composite bar is not limited to bends, as traditionally used in steel production, but allows far more complex, organic freeform spline sections,” says Schulz. (Splines, in computer design, refers to curves that connect or are defined by two or more specific points.) All of this enables significant design freedom during the CAD and FEA processes, for which IFA Technology and IFA Composite use the composites software suite from ANSYS Inc. (Canonsburg, PA, US).

The outcome of these efforts is a part made using carbon fiber prepreg. “This choice allows for superior consolidation in the parts, resulting in consistent stiffness and lifetime expectancy,” says Schulz.

Given its long history in producing reliable suspension parts from glass fiber prepreg, IFA Composite designed and manufactured this new carbon fiber prepreg in-house, using a specially formulated epoxy matrix system. The company uses a smaller volume prototype line and a full-scale inline impregnation line (See Step 2 and Fig. 3, at left) supplied by Santex AG (Tobel, Switzerland).

With a final design in hand and materials selection complete, the next step was preform manufacture. “It is critical that all fiber angles are exact, so we designed a special machine to cut and assemble the prepreg layers,” Schulz explains. Currently, only the assembly process is machine supported. Preforms are then placed by hand into a single-cavity tool, which has been prepared using mold release from Chem-Trend Germany (Maisach/Gernlinden). The tool is then closed and the inner silicone bladder is inflated with air.

“When we started in 2011, the curing cycle was 40 minutes,” says Schulz, “but now it is reduced by half, to less than 20 minutes, using 1 MPa pressure at 130°C.”

When the part is cured, the liner is removed and the parts are post-cured for two hours. For the current limited-production quantities, molded parts are trimmed and drilled manually. When production volume increases, this will change to CNC- machining, similar to the company’s process for leaf springs (see Step 5).

Prototype parts are tested in IFA’s extensive test center (which houses burst, crash, noise/vibration/harshness (NVH), acoustics and service-life test systems as well as climate chambers capable of -41°C to 75°C and up to 80% relative humidity) against real road data diagrams defined by the OEM. Automated nondestructive testing equipment is available for both prototype and production parts (Step 6). The CFRP stabilizer bars for the Volkswagen XL1 passed all required performance tests, yet weighed only 786g for the rear axle and 1,159g for the front. Those weights are extremely low, however, because the XL1 hybrid is designed to travel 100 km on one liter of fuel. Newer stabilizer bars designed for high-performance sports cars weigh closer to 1,250g, but that is still half the mass of their metallic counterparts.

Opportunities for carbon and glass

IFA Composite already is using the process developed for its stabilizer bars to broaden its pursuit of production- scale CFRP suspension structures. It has since developed structural CFRP chassis components that include not only leaf springs and anti-roll bars, but torsional springs and other suspension parts — and broadened its production to other high-performance automobiles.

Although the XL1 stabilizer bar uses a monolithic design, Schulz sees growth in multi-part assemblies, similar to those developed for a new sports car. “It allows even more design freedom with mix-and-match lever arms and also hollow torsional tubes,” he explains. “With almost the same weight as the XL1 parts, these stabilizer bars are six times stiffer!”

The big question is will this technology go into high-volume production? IFA Composite’s product group leader Hinrich Hampe sees that future for CFRP and GRP chassis components. “The advantages, like good failure modes and lightweight design, are valued, both for today’s cars and future models,” he says. “We also see options for torsional springs, which can be made more compactly than metallic components, opening up totally new layout options.” Hampe adds, “Due to the high cost of carbon fiber raw material, it will be limited to sports cars and electric vehicles, but glass fiber offers an alternative still underestimated today.”

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

World's first glass fiber leaf spring for 40-ton trucks

IFC Composites moves beyond its light truck composite leaf springs for Daimler, developing a heavy commercial truck version that cuts 400 kg vs. steel.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More