Integrated, optimized aircraft door

This composites manufacturer is betting its one-piece 3-D preform and RTM process will trim weight from today’s fastener-intensive “black aluminum” aircraft doors.

Historically, one of the most common, but erroneous, assumptions made by engineers when a commercial aircraft component is converted from aluminum to carbon fiber composites is that the process is a simple matter of “dropping in” composites as a 1:1 replacement for the metal — hence, the colloquial misnomer “black aluminum.” The result is often a structure that, although it weighs less than its aluminum forebearer, is overengineered and is, therefore, still heavier than necessary. The risk, of course, is that the composite-for-metal conversion, no simple task, is unlikely to be designed in such a way that it takes full advantage of the mechanical benefits the composite material could convey. Today, composites engineers prefer to speak of “optimizing” a part for composites. That is, when a composite part will replace a metal one, the metal part’s form, fit, function and part list do not dictate the composite design. Instead, the part is reengineered, as if the part had no history in metal. This clean-slate approach permits designers to conceive of a composite structure with the best balance of strength to weight and manufacturability.

If, where and how composites were overengineered on The Boeing Co.’s (Chicago, Ill.) 787 Dreamliner is debatable and will be fairly judged only by history. But because the plane is the first commercial jetliner to employ carbon fiber on such a large scale, it’s probably fair to assume that not every composite part is designed for optimum performance. It’s probably also fair to expect that creative composites engineers will seek business opportunities to perfect suboptimum composite parts on both the 787 and its forthcoming competition, the Airbus (Toulouse, France) A350 XWB.

One such opportunity has already been discovered. As early as 2006, composites manufacturer Latécoère (Toulouse, France) struck upon the notion that the Type A composite passenger door, the basic structure of which is dictated by safety requirements, might, with some creative design and engineering, be made even lighter. Common to the 787, A350 XWB and other commercial aircraft, a Type A door is approximately 2,000 mm tall by 1,250 mm wide by 200 mm thick (78.7 inches by 49.2 inches by 7.9 inches), with a radius of about 2,100 mm (82.7 inches). It features six to eight attachment points along each side. The Type A door varies according to aircraft model, primarily in the location of the attachment points, which can be positioned as necessary to accommodate hinges and latches, and the radius, which is dictated by the radius of the particular plane’s fuselage. Like the rest of the fuselage, the door is stressed primarily by pressure exerted from inside the aircraft at cruising altitude — about 3.5 to 4.5 metric tonnes (7,716 to 9,921 lb) per fitting.

Jean-Christophe Ichard, head of composite materials and processes at Latécoère, says the company’s initial assessment of an optimized Type A door was promising, but other projects took priority and the opportunity was shelved until about 2008. Latécoère then took up the effort in earnest and began a design “from scratch” for a Type A door. The project, called COMDOR (short for composites door) focused on matching the material, tooling and process with the application. “A new design approach was followed by always thinking ‘composites,’ not only for manufacturing but also for load introductions,” says Ichard. “The target was also to be close to certification and qualification requirements applicable to passenger doors.”

The goal, he says, was to develop a door that features a unified, unbounded, fastener-free structure that could be molded via resin transfer molding (RTM). “The most challenging aspect was to define a design compatible with stitching and RTM process,” says Ichard, “and in the meantime, meeting aeronautical requirements and specifications.” Also at stake was the labor intensity and cost associated with about 800 titanium fasteners currently employed on Type A composite doors to attach separately molded stringers, beams and the frame to the skin of the door. An additional challenge, then, says Ichard, “was to design a door structure without fasteners in beam and frame areas.” It was determined that a completely unified structure that eliminates such fasteners through parts consolidation would require development of a stitch-bonded 3-D preform compatible with the RTM process.

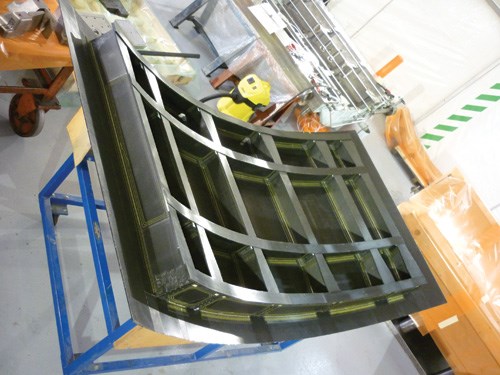

To design the door, Latécoère relied on CATIA V5 (from Dassault Systèmes, Paris, France) with the Composites Product Design (CPD) module. PATRAN/NASTRAN software was employed for component sizing. The company also used other software to optimize the manufacturing process, such as PAM-RTM, an RTM simulation program from ESI Group (Rungis, France), and KUKA Sim Pro, a robotic programming system from KUKA Robot Group (Augsburg, Germany). The 3-D structure that emerged integrates a skin of eight carbon fiber plies backed by a box/grid network of similarly stacked stringers and beams — six stringers arranged horizontally to provide load support for edge fittings and four vertically oriented beams. All of the fabric and resin used would be supplied by Hexcel (Stamford, Conn.), including HexForce G0926 carbon fiber fabric (370 g/m2, 0.38-mm/0.015-inch thick) and RTM6 epoxy resin. From the front, the door would present a smooth skin to match the surface of the fuselage. From the back, the door would consist of stringers and beams that provide structural integrity, with fittings provided at the end of each stringer for door hardware.

Big, complicated preform

When this stitch-bonded preform design was settled upon, says Ichard, engineers sought to determine the best strategy for cutting, assembling and stitching the preform’s disparate parts together. In all, Ichard’s group developed 45 fabric forms that would be used to construct the stringers and beams and the skin of the door. Ichard notes that the requirements were straightforward: the cuts must be clean, without fraying the fabric; the cuts must not cause thread pullouts; and the dimensions must be absolutely accurate to allow precise placement of the preform in the mold tool.

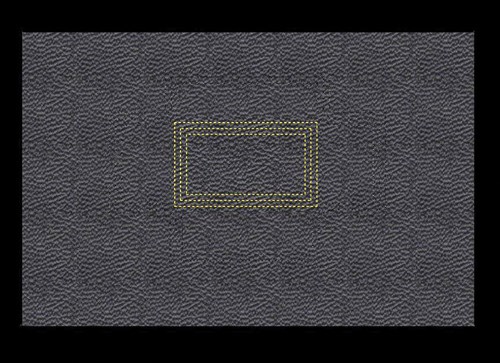

Latécoère, says Ichard, first assembled the plies and stitched them together as one large fabric. This was done on a stitching table, and the individual beam and stringer preforms were stitched in serial fashion (see Step 2 photo). Although Latécoère would not identify whose stitching machinery it used, Ichard does say that flat and contoured stitches were employed. The skin laminate for the door was similarly assembled, and then the large fabric was cut to form, creating the needed shapes.

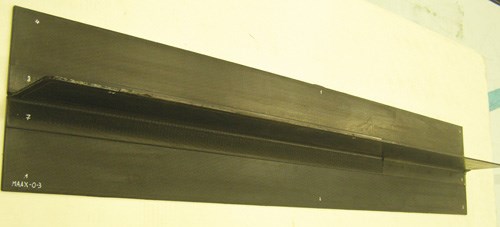

The company opted for a 2-D cutting strategy to produce flat shapes that would then be folded to build and connect the 3-D preforms. Ultrasonic cutting via a KUKA robot was used, and Ichard says quality from this method has been excellent. The resulting flat pieces vary in shape and size, depending on where and how they are used in the door. The longest preforms are the horizontal stringers that consist primarily of flat, eight-ply laminates about 5 inches/127 mm wide and almost as long as the door is wide. These are intersected by the vertical beams of the same width, which are tabbed and sewn into the stringers perpendicularly (see Step 5 photo) and feature another tab for a T-bond with the skin.

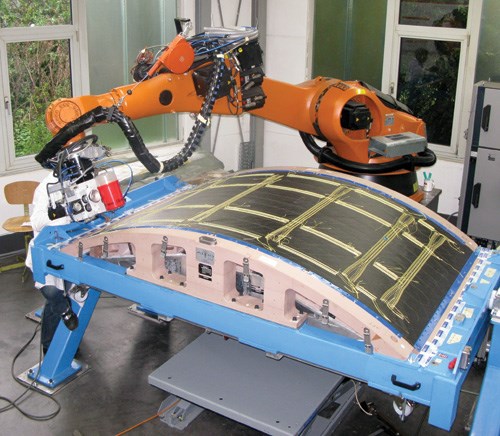

Next, Latécoère was faced with the daunting task of placing, securing and stitching together the 45 preforms and the skin. This, says Ichard, is where much of the company’s proprietary technology resides. However, he did reveal that Latecoere designed the stitching tool, but had it manufactured by an unidentified third party. This tool, designed to resemble the shape of the door, is oriented horizontally for the stitching operation, with the outside of the tool facing up and the inside of the tool facing down. The skin fabric is placed atop the tool facing up toward the stitching head, attached to the end of a KUKA multiaxis robot that works over the tool. On the underside of the tool, meanwhile, the 3-D preforms that will form the stringers and beams of the door are held in place against the back of the skin, ready to be stitched into place against the skin laminate. The robot works on top of the tool, stitching through the skin and into the preforms on the other side.

How the preforms are held in place under the stitching tool, Ichard would not say, except to admit that “it is very tricky and complicated.” Radius fillers were added at the intersection of several skin, stringer and beam sections. The company also stitched on top of each stringer and beam a stack of uni carbon fiber plies to provide stiffness.

The result is a fully unified carbon fiber fabric structure that is smooth on the skin side, with 3-D frames, beams and stringers stitched to the back side. This one-piece structure is now ready for molding. Design of the RTM system involved Latécoère, Compose and RTM specialist agency PPE (previously known as Pôle de Plasturgie de l’Est (Saint-Avold, France), as well as injection machine manufacturer ISOJET Équipements (Corbas, France). The preform, says Ichard, is hand placed in the Compose tool, skin side down. The cycle time for the structure was not revealed, but Ichard admitted that significant development work went into making sure that, during infusion, the resin would fully wet out the preform and leave no dry spots.

The as-molded part is nearly net shape, requiring only cutting and trimming of the radii at the corners of the door frame to conform to the door shape. This is done with a 5-axis machining center. The stringers also are drilled at the ends to facilitate installation of door attachment fittings. Ichard reports that Latécoère’s COMDOR door weighs 15 percent less than current black aluminum composite door designs. Further, he says that tests show the pull-out strength of the stitch-bonded stringers and beams at least equals that of the current design, which employs titanium fasteners.

Moving forward

The COMDOR door, it turns out, is just the beginning for Latécoère, and it will be followed by the company’s effort to place this structure on a functioning aircraft. Ichard says Latécoère has moved into phase two of composite door development, having launched the Maaximus project. Partially funded by European government agencies, Maaximus will develop a fully functional door that incorporates copper mesh in the skin for lightning protection, glass fiber in selected locations to protect against galvanic corrosion, and a different thread for stitching. (Ichard was careful to note that all of the preform and molding technology developed for COMDOR and Maaximus is owned and controlled solely by Latécoère.)

The Maaximus door, Latécoère hopes, will weigh 5 percent less than the COMDOR door, for a total 20 percent weight reduction, thanks to material and process optimization.

Ichard says the company expects to test the Maaximus door under pressure on a test fuselage barrel structure beginning in September 2012 and ending in January 2013. If all goes well, this testing should be followed by a technological readiness review in March 2013, and then full fuselage barrel testing in the 2013-2014 time frame. After that, Latécoère expects to place the door on an in-service commercial passenger aircraft.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More