FEA facilitates custom megayacht design

Modeling software and design ingenuity meet vibration challenges in ocean-going luxury yacht.

Engineering Challenge:

A custom yacht buyer’s request for large, open interiors compromises structural stiffness in the vessel’s initial design, resulting in racking motion during vibration load simulations.

Design Solution:

Finite element analysis shows that the racking problem can be solved with the addition of a composite “racking frame” that stiffens the hull structure without sacrificing living space.

The lucky individuals who have the resources to afford a megayacht — a custom, crewed vessel, typically in excess of 30m/100 ft in length and costing millions — have come to expect not only a seaworthy vessel, but also luxurious interior spaces. Large, open yacht interiors are a decorator’s dream, but they can be a naval architect’s nightmare because they complicate the structural design.

One notable example is Mr. Terrible, launched in 2007 and outfitted with expansive and sumptuous interiors that added extra weight and posed major composite design challenges for Delta Marine Industries (Seattle, Wash.).

Delta Marine project engineer Chad Caron, a naval architect and a professional engineer, credits composite materials with enabling greater design flexibility. ”We can tailor them to a high degree, as we did for Mr. Terrible.” But he points out that, in this case, success might have been elusive without the service of finite element analysis (FEA) software.

Modeling a monster megayacht

Although Delta got its start using composites to build commercial fishing vessels to withstand harsh conditions in Alaska, it made the transition to its current specialty of large luxury motoryachts in the 1980s. Today, says Caron, “a client comes to us with a concept. Our job is to realize and clarify that concept with a purely custom design.”

The first step is to establish how the vessel will be used — for example, long cruises require additional fuel storage, while visits to small ports with shallow water necessitate a shallow draft. For Mr. Terrible, notes Caron, the client wanted a glamorous showpiece that could travel at relatively high speed. For that reason, Delta Marine targeted a semidisplacement hull — one shaped to lift slightly out of the water and over its bow wave when under power. This decreases the hull’s wetted length and, thus, reduces drag, resulting in greater speed than a simple displacement hull, explains Caron. Delta Marine maintains several semidisplacement hull mold shapes that can be modified slightly for each project — for Mr. Terrible, total length was 47m/154.2 ft and beam was 8.8m/28.9 ft, with a 2.2m/7.2-ft draft. After the general hull configuration was defined, Caron began his structural design by determining the loads the composite vessel would have to resist. “Essentially, you start by envisioning the boat as one large beam,” he explains. Determined with an assumed weight estimate, first-order bending moments — sagging, when supported at ends by two waves, or hogging, when riding on one wave, amidships — can be on the order of 8,135 kN-m (6,000 kip-ft). Added to that are acceleration loads — heave and surge, roll and pitch — caused by wave action. At the next level, he calculated wave slamming and pressure loads (caused by standing water on the deck, for example). Finally, says Caron, he considered “stress intensifiers,” such as planned hull penetrations that accommodate the bow thrusters and other equipment. In line with the client’s request for speed, the hull had be designed to resist these loads at minimal weight.

Given these performance requirements, the boat’s general composite structure was developed based on Delta Marine’s in-house design parameters, which Caron says have been verified by rigorous in-house testing and through property testing by material suppliers. Rather than rely on traditional scantlings (structural design data) provided by major classification societies, such as Lloyd’s Register (London, U.K.) or the American Bureau of Shipping (ABS, Houston, Texas), Delta uses its own proprietary design strategies that Caron says are more rigorous.

“We design beyond the rules provided by the classification societies,” he explains. “We do use those general rules as a cross-check for our customers if they wish to be ‘classed.’” (For a fee, a yacht buyer can have the vessel inspected, classed and registered by a society, as a means of documenting seaworthiness for insurance purposes. Mr. Terrible is now registered by ABS.) Knowing that the interior spaces on this project would be substantial, Delta Marine selected carbon fiber reinforcement for the majority of the hull and deck structural composites to maximize performance and, in the case of the decks, stiffness, with minimal weight.

As the design progressed, the primary shapes and dimensions of the vessel’s components were determined in Rhinoceros 3D software from McNeel North America (Seattle, Wash.). For Mr. Terrible, the hull below the waterline was designed as a solid laminate, for better resistance to impact damage, while cored sandwich structure was employed above the waterline and in three horizontal decks: the flybridge, the boat deck (with the main living area) and the lowermost weather deck. It was here, where the deck layout had to accommodate unusually expansive interior spaces, that designing the structural support elements and engineering the load paths between the decks became very complex.

“Traditional design methods, like handbook formulae or rules of thumb, are not adequate to achieve an optimized structural assessment for a vessel of this size and complexity,” notes Caron. “We had to perform finite element analysis on a global basis to adequately develop the integrated structure.” Delta Marine employed ANSYS Mechanical software from ANSYS Inc. (Canonsburg, Pa.) because of its ability to model layered shells and solids, allow property specification on a ply-by-ply basis, and predict laminate failure modes. The Rhinoceros solid model was exported to a neutral file format and then imported into ANSYS Mechanical to provide the geometry for the FEA model mesh. Caron built the model, using the shell elements to represent the laminate stacks of the vessel’s side shells and decks. Solid elements represented support components, such as longitudinal girders and transverse beams in the hull.

FE analysis reveals “racking”

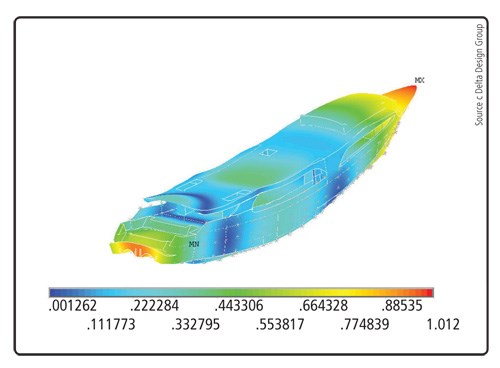

The software not only helped to optimize the vessel’s structure via laminate behavior prediction, but also was able to model response to vibration frequencies by performing vibration modal analyses. Vibrations, which result from wave impact as well as the vessel’s engines, must be minimized for customer comfort, so predicting them is an important part of the overall analysis, says Caron. He used Delta Marine’s in-house data to estimate interior weights, using per-square-foot targets for various materials. These “outfit” weights, together with the structural and mechanical weight components (i.e., engine, drives and fuel), coupled with the hydrodynamic loads imposed by the water, determined the yacht’s overall weight estimate and enabled calculation of vibration frequencies and mode shapes during operation.

According to Caron, the FEA modeling results revealed that the yacht, as designed, would experience a “racking” vibration mode. That is, the boat’s superstructure and the lower decks moved back and forth horizontally in opposite directions. “Think of a large cruise ship, with hundreds of cabins,” Caron illustrates. “It never experiences racking problems because the numerous transverse cabin walls make the ship stiffer,” notes Caron. By contrast, the combination of Mr. Terrible’s open interior, with its very few transverse bulkheads, and the weight of the luxurious trimmings throughout compromised the structural stiffness. “Essentially, the vessel was behaving like a deck of cards, with the cards sliding past each other and decoupling structurally.” A fix was needed to minimize the racking, yet maintain the customer’s primary design brief.

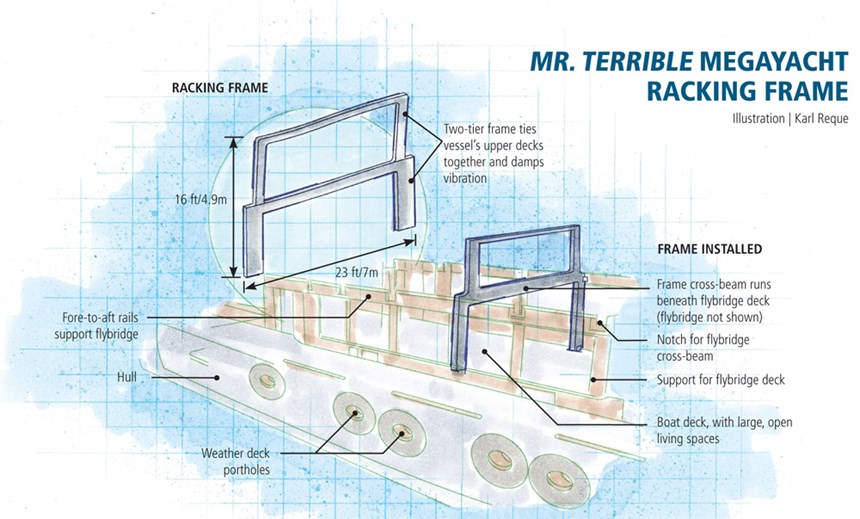

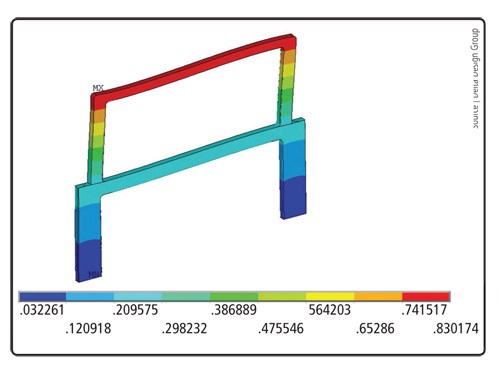

Without the option of adding interior walls, Delta instead designed and built a composite “racking frame,” an open rectangular framework that vertically spans all three superstructure decks and ties them together (see computer rendering, above). The frame design specified multiple plies of biaxial (±45°, 0/90°) and unidirectional fabrics, to resist shear forces caused by the vessel’s vibration. The 4.9m high by 7m wide by 178-mm deep (16.1-ft by 23-ft by 7-inch) frame, with a laminate thickness of about 25 mm/1 inch, was situated amidships above a transverse bulkhead below the weather deck and taped (wet laminated) to structural mullions on each side of the vessel. Functionally, the frame not only ties the vessel together structurally, but its composites also act to damp the vibration and minimize frequency transmission between living areas.

The frame was fabricated by hand layup of dry carbon and glass fabrics supplied by Vectorply Corp. (Phenix City, Ala.) and OCV Technical Fabrics (Toledo, Ohio). The layup was vacuum infused using a room-temperature-cure vinyl ester resin from Reichhold Inc. (Triangle Research Park, N.C.).

Mr. Terrible’s final hull design included a solid, uncored monolithic laminate below the waterline, made up of approximately 18 plies of stitchbonded glass fabric, with 30-plus plies making up the keel. Above the water, the cored sandwich construction featured 50-mm/2-inch thick balsa core from Alcan Baltek (Northvale, N.J.) faced with hybrid fiberglass and carbon fiber skins, made up of 14 plies of stitchbonded biaxial fabric that incorporates continuous fiber mat on the back side, supplied by Vectorply and OCV. Decks were made in the same manner, but with thinner skins. The hull and deck builds were accomplished via wet layup and vacuum infusion, using the same Reichhold resin.

Tailored design with FEA

Caron says Delta’s design process enabled him to determine exactly how loads are distributed through the complex structure, so that the structural elements could be tailored to provide strength and stiffness where needed. “We put walls and partitions where the client wanted, while keeping weight to a minimum,” Caron sums up. But he is careful to point out that “this is a tailored solution that would not have been possible without modeling,” adding that FEA software “was instrumental for predicting the laminate behavior under load, as well as helping to define the frame’s design.”

Dipankar Choudhury, VP of product strategy and planning at ANSYS, concludes, “Modeling software makes it possible for a boatyard to create yachts with interiors based on aesthetics, and not just structural considerations.”

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreGKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Megayacht Composite Masts Get Smart

Freestanding square rigging is fully instrumented for structural health monitoring while under sail.

Read MoreCompetitive to the core

This new superyacht combines luxury innovations with energy-efficient construction, enabled by a new marine-grade balsa core.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More