Form + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

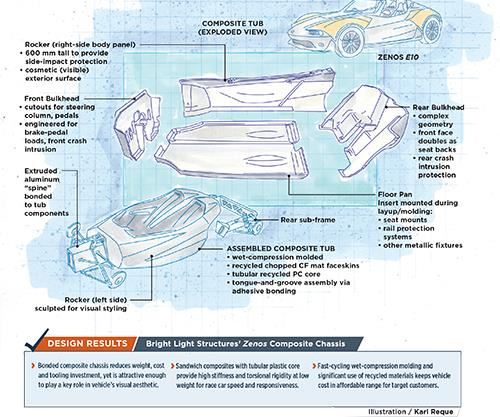

Design Results:

- Bonded composite chassis reduces weight, cost and tooling investment, yet is attractive enough to play a key role in vehicle’s visual aesthetic.

- Sandwich composites with tubular plastic core provide high stiffness and torsional rigidity at low weight for race car speed and responsiveness.

- Fast-cycling wet-compression molding and significant use of recycled materials keeps vehicle cost in affordable range for target customers.

The conventional car chassis is engineered to meet mechanical load and crash performance, durability and noise/vibration/ harshness (NVH) requirements, but isn’t expected to be beautiful. Hidden by “dust covers” (the industry’s euphemism for exterior body panels), a chassis is on view only to mechanics and weekend do-it-yourselfers. But startup automaker Zenos Cars Ltd. (Wymondham, Norfolk, UK) recently asked, “Why pay to produce chassis components, then pay more to hide them?” The answer? The Zenos E10, which demonstrates that you can make a chassis beautiful enough to play a visible role in vehicle styling and make the car more affordable in the process.

Keep it simple, cost-effective

The E10 chassis is produced by Bright Lite Structures LLC (BLS, Peterborough, Cambridgeshire, UK), based on a design and material developed by Antony Dodworth, now BLS’ chief technology and manufacturing officer. An important and early OEM program requirement was to keep component, tooling and assembly costs low to better manage cost of ownership (the E10’s base sticker price is £26,995/US$39,027) and, because it is a race car, keep weight low to optimize speed and handling. The team knew that one of the best ways to do both was to use composites in structural assemblies, not just body panels.

“Our design philosophy going into this program was to make the chassis as simple, attractive and low cost yet functional as possible by maximizing parts consolidation and integrating assembly features,” explains Dodworth. “We literally wanted to be able to ‘clip the car together’ and then bond it with structural adhesive.”

The final chassis assembly design comprised five carbon fiber composite parts — front and rear bulkheads, floor pan and left and right body side panels (rockers) — bonded to a central aluminum spine (see drawing below). The greatly reduced part count improved vehicle quality — fewer parts equal fewer stack-tolerance issues — and a follow-on benefit was manageable tooling costs (£250,000/US$283,400) for production volumes of 300 sets annually. Assembly time and costs were reduced by molding in bracketry and designing components to slot together tongue-and- groove fashion prior to bonding with Dow Automotive Systems' (Midland, MI, US) BetaMax 2700 series adhesive, which has good flexibility, gap-filling properties and reduces noise transmission.

“Of course, it’s very easy to say ‘let’s make it as simple as possible,’ but it’s an entirely different thing to accomplish that,” Dodworth quips. “Until we started making parts, we didn’t realize how brave we’d been.”

To meet crash performance challenges, tubular-steel roll bars are bonded to molded features on the rear bulkhead (the front face of which doubles as the seat back) to help transfer loads from the spine to mid-chassis, boosting stiffness and protecting occupants in this open-cockpit sports car, thereby making the rear bulkhead a load-carrying member. Similarly, the door-less car’s tall 600-mm rockers/sill plates form a vertical wall that occupants must climb over to enter/exit the racer, but eliminate door cutouts and, there- fore, preserve torsional rigidity.

Designing a better sandwich

To realize the E10 design, however, BLS needed a new sandwich composite. In pursuit of a better sandwich-panel design since his days as R&D director at Bentley Motors (Crewe, Cheshire, UK), Dodworth first looked into Bentley parent company Volkswagen AG’s (VW, Wolfsburg, Germany) composite rear package shelf. It’s made with BayPreg spray honeycomb composite and features polyurethane (PUR) resin-impregnated chopped glass from Covestro LLC (formerly Bayer MaterialScience, Leverkusen, Germany) with paper cores from SWAP (Sachsen GmbH, Frankenberg, Germany). More than 1 million parcel shelves are produced annually using wet compression molding. Inspired by the material/process combo, Dodworth tried it for structural applications, but found it wasn’t strong enough even when carbon replaced glass fiber.

To make it tougher and stronger, Dodworth worked with Dr. Michael Connolly, program manager, urethane composites, at Huntsman Polyurethanes (Auburn Hills, MI, US), and after Dodworth left Bentley to form Dodworth Design (which merged into BLS in 2014), the pair settled on a custom grade within Huntsman’s VITROX PUR line. VITROX HC 98010 polyol and SUPRASEC 9801 isocyanate offer a good physical-property profile, strong adhesion to the core and good impact strength/toughness at a given resin Tg. The PUR’s low and stable viscosity enables rapid, thorough fiber impregnation, and its novel catalyst permits long, yet tunable working times followed by a snap cure, making it suitable for large parts.

Notably, the E10’s matrix is a blend of this PUR and a resin transfer molding (RTM) grade of epoxy. Used alone, the spray and air-exposed urethane would be microporous when cured. The epoxy seals the matrix, prevents vapor/moisture issues, eliminates pinholing and helps tune the composite’s energy management for better crash performance. Both polymers are mixed (BLS won’t reveal the ratio) just before spraying with an Auto RIM seven-component mixhead from Hennecke Inc. (Lawrence, PA, US).

Although “green” wasn’t a Zenos design criterion, Dodworth had been developing sandwich composites for a European automaker that prizes “green” technology, so a source of recycled chopped carbon fiber (nominal length 35 mm) was used for both projects. The chopped fibers are formed into a non-crimp fabric (NCF) mat, held in place by nylon stitching and the binder left over from the original reclaimed tricot-patterned carbon weave fabric.

Because Zenos sandwich panels are used in stiffness, not strength-driven designs, the discontinuous-fiber mat is more than sufficient to meet performance requirements. The mat stretches during molding to accommodate the chassis’ deep-draw designs. After impregnation, nominal fiber volume fraction (FVF) for skins ends up in the “high 30s/low 40s” according to Dodworth. The recycled-fiber NCF is “fluffy” and 50% thicker than comparable-weight virgin NCF, so wetout requires a lot of resin. A single ply of NCF is used on either side of the core for all parts except the load floor, where seatbelt pullout requirements necessitate use of two additional plies of continuous-fiber virgin NCF, laid up in a 0/90o/±45o pattern across the top face.

Dodworth also developed a new core from recyclate. He wanted a stiff, light, torsionally rigid material, yet one capable of some flexibility when molding complex parts, which ruled out crushable paper and wood cores. A desire for equivalent properties in all directions suggested a tubular rather than a conventional hexagonal honeycomb structure, an idea Dodworth conceived while playing around with thermoplastic drink straws from the local McDonald’s.

Cut and glued together, then molded between fiber-reinforced polymer skins, the tubular core worked in principle. The challenge was to find an industrial source of “straws” to form sheet core. Polycarbonate (PC) was selected because its Tg is similar to that of PUR/epoxy at the 130oC molding temperature. A source of recycled PC was found that was far less costly than virgin. The recycled polymer is extruded through a laser-cut metal plate to form hollow tubes (internal diameter 7 mm). While the tubes are still warm, they’re pushed together, and where they touch, they permanently bond as they cool, forming a stiff but light core.

Like the VW package shelves, the E10 chassis components are wet compression molded. The process can form 3D designs that would be difficult to realize in most other composite molding processes without costly preforming, and is equally appropriate for prototyping or high-volume manufacturing, which further reduces component costs and cycle times.

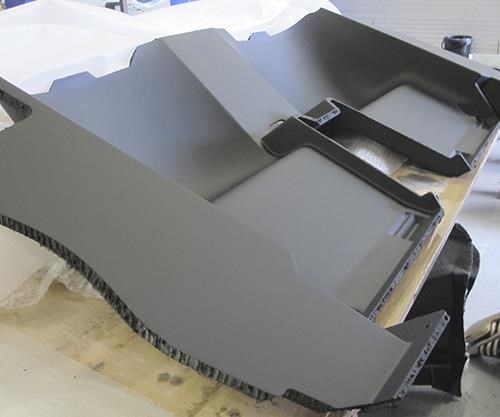

Aluminum matched-metal dies are used (one tool set for each of the five parts), so parts exit the press with two good faces whose texture and aesthetics can be different. Layup is done by hand, but material is shuttled to impregnation and molding stations via robot. Thanks to use of recycled materials, 83% nesting efficiency and the relatively simple exterior geometry of parts, the process reportedly generates far less scrap than conventional composites molding systems, yet testing shows it produces parts of comparable performance at lower cost. BLS uses 6-bar molding pressures and a 12-minute button-to-button cycle. Total cycle time, including kit cutting, layup and post-mold trimming, is 15-20 minutes per part, although that could be reduced further with more automation.

Driving Zen

The chassis meets or exceeds the vehicle’s compression, stiffness and torsional rigidity requirements while reducing weight 15-20% vs. aluminum. It also offers greater design flexibility than conventional monolithic composite materials. Although the chassis components do not have Class A surfaces, they receive two coats of primer and one coat of matte-black paint to cover dimpling (core read-through) and create a uniform, non-reflective surface. Depending on model and options purchased, curb weight of the vehicle ranges from 630-700 kg, making it roughly 300 kg lighter than a gracile Lotus Elise.

A year into production, the chassis is making significant contributions to safety, as several cars have sustained spectacular real world crashes on track and road, and vehicle occupants have walked away unharmed.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)