JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

- Wind/Energy

- Cutting/Kitting

- Sustainability

- Automotive

- Sheet Molding Compound

- Pultrusion

- Defense

- Carbon Fibers

- Out of Autoclave

- Composites 4.0

- Molds/Tools

- Machining/Drilling

- Materials

- Glass Fibers

- Fabrics/Preforms

- Pressure Vessels

- Adhesives

- ATL/AFP

- Weaving

- Consumer

- Processes

- Epoxies

- Resins

- Thermoplastics

- Aerospace

- Natural Fibers

- Mass Transit

- Reinforcements

- Design & Tooling

- Markets

- Marine

- Injection/Overmolding

- Autoclave

- Construction

- Hi-Temp Resins

- Compression Molding

- Ketones

- Additive Manufacturing

- Braiding

- Design/Simulation

- Prepregs

- Nanomaterials

- RTM

- Curing

- Medical

- Infusion

- Materials Testing

- Core

- Filament Winding

JEC World 2017, the largest composites event in the world, will be held at the Paris Nord Villepinte Exhibition Center, near Charles de Gaulle airport outside Paris, France. Held March 14-16, the event will showcase many new technologies in the composites world, one of the most technologically creative and innovative sectors within the manufacturing sector.

CompositesWorld polled a number of the exhibitors who will be on hand, asking them for an advance indication of what they’d have on display in Paris. The following is what those who walk the aisles at Paris Nord Villepinte will see in the following companies’ stands.

Core materials

3A Composites AIREXBALTEKBANOVA (Sins, Switzerland) will showcase its new products AIREX T10.60 and BALTEK VBC QX, based on PET foam and balsa composite materials.

Braided fiber reinforcements

Braided reinforcements specialist A&P Technology Inc. (Cincinnati, OH, US) says TX-45, a new ±45° product, will make its debut. TX-45 was introduced by A&P as a standard product in early 2017. TX-45 is a low cost, continuous 45° fabric with uniform fiber architecture. It is a ±45°, 193-g/m2, 2x2 twill delivered on carrier paper to enable easy handling and consistent fiber orientation. A&P says TX-45 was developed for an aerospace customer interested in a substitute for a ±45° plain-weave prepreg. A&P says the cost and time savings enabled by TX-45 and its superior mechanical performance has attracted the attention of many prepreggers and end-users.

Other products on the A&P stand will include QISO, a single-layer, quasi-isoptropic fabric used in aerospace applications, industrial applications, composite tooling and communication dishes; Bimax, ±45° fabric stabilized with hot melts across the width, providing consistent fiber orientation; and ZERO, cost-effective, non-crimped unidirectional fabric. A&P’s fabrics can be produced with any fiber type, are available in a variety of widths and areal weights, and can be customized to meet specific part requirements. www.braider.com

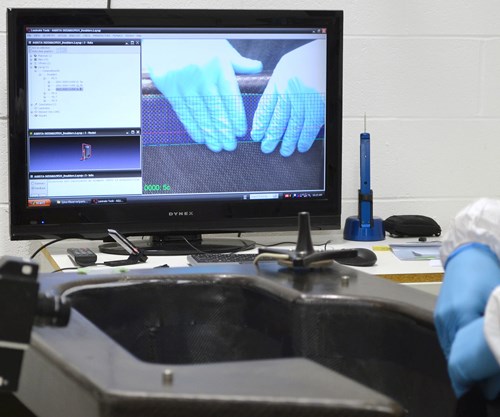

Ply placement software

Anaglyph Ltd. (London, UK) will demonstrate PlyMatch hand layup ply placement technology. PlyMatch uses augmented reality to show the live combined images of actual and target ply outlines and fiber orientation details on a monitor, so that the two can be matched by the operator. PlyMatch is used for the accurate placement of plies in hand layup manufacture of composite parts, as well as for monitoring and validation of automated methods. It is said to be particularly useful in case of complex geometries, with high-curvature or enclosed spaces. Anaglyph will also feature Laminate Tools, to address the design-analysis-check-manufacture process of structural design, but focusing on the composite material features. Laminate Tools has native interfaces to SOLIDWORKS, Rhino, Nastran, Ansys and Abaqus. Also featured will be CoDA (Composite Component Design Analysis), used for preliminary analysis subcomponents with plate, beam, joint, flange or laminate geometries. CoDA is available as seven independent, but integrated, modules. Finally, LAP (Laminate Analysis Program) is used to analyze any type of composite laminate subjected to in-plane loads and moments. The flat laminate is no fixed size, apart from its thickness, so that the analysis can be applied to any composite component where loadings and deformations are known.

Pollution control systems

Anguil Environmental Systems Inc. (Milwaukee, WI, US), which designs, manufactures, services and installs thermal and catalytic oxidizers as well as heat recovery systems, is featuring its air pollution control technologies currently used for carbon fiber manufacturig processes. The proprietary designs offer high destruction efficiency, low greenhouse gas output and energy recovery options for powering process systems. Other systems made by Anguil and targeted toward composites manufacturing opterations destroy hydrogen cyanide (HCN), silicone, styrene, NOX and odorous emissions.

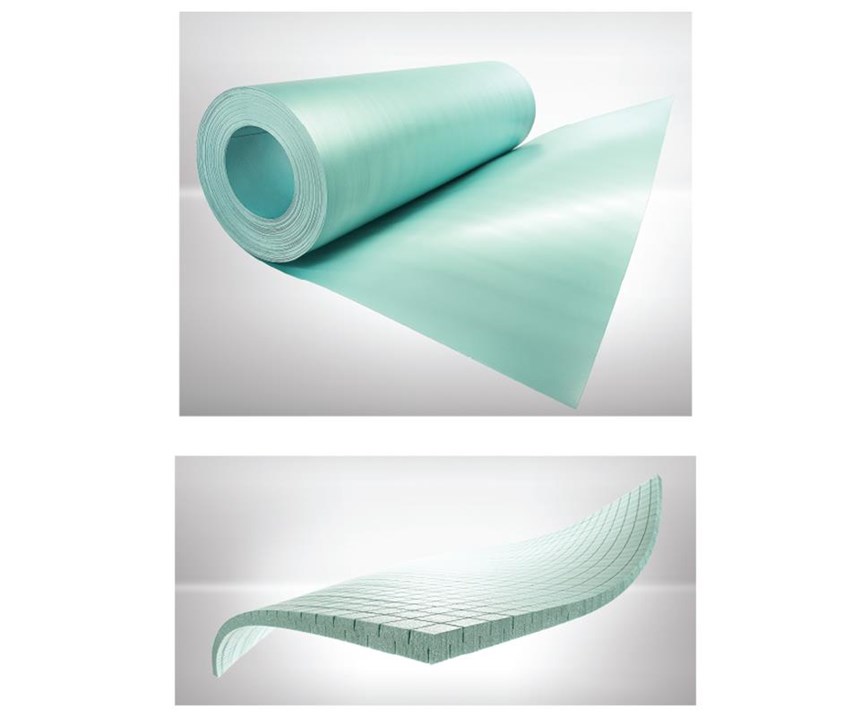

Structural PET foam core

Armacell (Thimister-Clermont, Belgium) is featuring its structural polyethylene terephthalate (PET) foam core product range, made entirely of recycled PET (see first photo, above). Armacell says ArmaFORM PET’s combination of material and processing properties (excellent fatigue endurance, elevated service temperature stability and compatibility with all resin and manufacturing methods) make it attractive for use in composite sandwich constructions in the wind energy, building and construction, rail and road transport and marine sectors.

Armacell reports that its trademarked ArmaFORM PET foaming process reduces CO2 emissions by 33% compared to other PET foam cores, which are made of virgin PET resin. The improvement is reportedly even greater when compared with polymeric foam cores, such as PVC (-52%), SAN (-46%) or PUR (-62%).

Two products will be featured: PET Core, a structural foam board offered in densities of 65-250 kg/m3 at thicknesses of 5-150 mm, is used in a range of composite sandwich applications, including rotor blades, train floors, building envelopes, truck bodies, boat hulls and radomes. ArmaFORM PET is used in >30,000 rotor blades globally.

PET Foil is a thin, flexible PET sheet available in thicknesses up to 6 mm, in densities of 70-300 kg/m3 and designed for applications that require stiffness and resistance. Designed to provide a highly sustainable alternative to crosslinked polyethylene (XPE) and polypropylene (XPP) products in thermoforming applications, PET Foil can be used with glass/polypropylene fabrics/felts or natural skins. It can also be used in most FRP sandwich structures where thin cores (<5 mm) are needed. www.armacell-core-foams.com

Plasma oxidation oven

C. A. Litzler Co. Inc. (Cleveland, OH, US) is introducing the world’s first 175-ton plasma oxidation oven for OPF and carbon fiber production. Litzler is working with 4M Industrial Oxidation LLC, a subsidiary of RMX Technologies, on this breakthrough technology. The patented 4M plasma-oxidation process will be key in the worldwide carbon fiber market expansion. It operates more than three times faster than current commercial technology and uses less than 25% of the energy per pound of fiber, also making it a "green" process. The equipment has been successfully tested for four carbon fiber makers and demonstrated quality fiber, increased throughput and significant energy reduction benefits. Plasma oxidation has also demonstrated improvement in the fiber quality versus conventional processing in some cases.

C. A. Litzler will also feature solution, hot melt and thermoplastic prepregging systems. Ancillary components include OPTI-FLOW ovens, unwinders, precision metering rolls and filmers, compaction roll sets, winders and accumulators. Litzler also supplies highly engineered roll stands with large-diameter rolls to minimize deflection, sizing stations and dryers, tension stands, Litzler automation control systems and the Computreater CF for development and testing of new fibers. Litzler also integrates furnaces, pollution control, surface treatment, creels and winders.

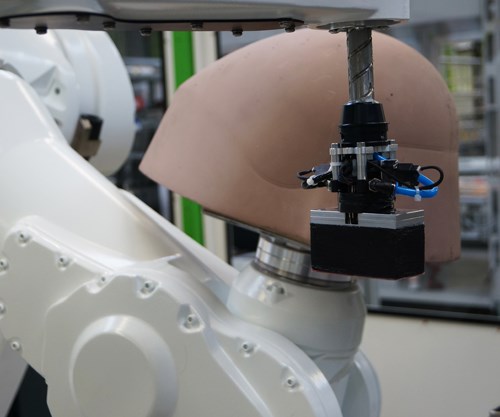

Optimized, automated laminate fabrication

Cevotec GmbH (Munich, Germany) will present ARTIST STUDIO, CAD-CAM software for generating optimized laminates and programming robots for fiber patch placement technology. The software matches SAMBA, the preforming system for challenging 3D geometries and laminates with complex fiber orientation, which will be presented live at the show. This industry-ready production solution for carbon composites enables the fully automated production of geometrically complex components in a continuous process from virtual design to preform.

Cevotec says ARTIST STUDIO significantly simplified production preparation and enables the fast creation of new production data in case of laminate changes. The software, with PATCH ARTIST and MOTION ARTIST, combines two modules that cover essential steps of the virtual product development process: PATCH ARTIST creates patch-based high-performance laminates with variable fiber orientation and variable component thickness. A proprietary algorithm ensures the laminate quality by optimizing the patch overlaps of a curvilinear fiber architecture. The virtual laminate is used by MOTION ARTIST to perform an automated and collision-free offline programming of SAMBA’s two interacting robots. The resulting production data is transferred to the preforming system SAMBA, which then produces the preforms fully automated. SAMBA uses a fast four-axis pick-and-place robot and a six-axis tool manipulation robot with a load capacity of 100 kg to place fiber patches on complex 3D molds. Thus, carbon fiber patches can be freely oriented at any point in the preform and follow curved load paths.

Potential applications for this technology include aircraft window funnels, motorcycle helmets, or medical orthoses and prostheses. In addition, both structural and secondary components can be reinforced to tailor mechanical properties, like seat backs in automotive and aerospace.

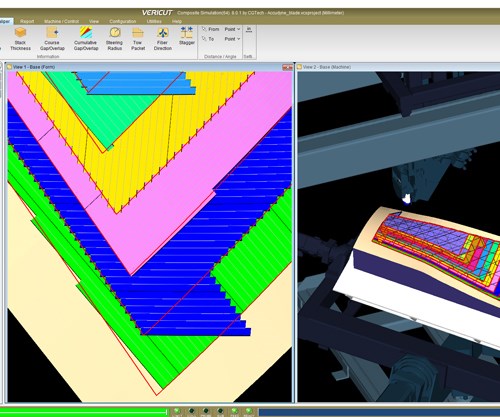

Manufacturing simulation systems

CGTech (Irvine, CA, US) will demonstrate how critical simulation is when trimming composite parts. Throughout the show CGTech will also demonstrate VERICUT Composite Applications: VERICUT Composite Programming (VCP) and VERICUT Composite Simulation (VCS). CGTech notes that, due to the extensive time, energy, and labor invested in composite workpieces prior to machining, they can often be more expensive than even some exotic metal alloy parts. Repairing composite workpieces after a machining error is problematic and many times not advisable. Thus, validating the part program prior to trimming is critical. Also on the stand, CGTech will exhibit its latest version of VERICUT 8.0 software, the company's CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving-out NC programs. VERICUT simulates all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robotics, mill/turn and parallel kinematics.

Visitors to CGTech’s stand will also have the opportunity to receive an overview of the steps needed to get from a CAD-designed composite part to CNC programs that drive an automated fiber placement (AFP) or automated tape laying (ATL) machine. There will be information on new projects that highlight the implementation and use of machine-independent, off-line NC programming software for AFP and ATL machines, such as the work being done at NASA's Langley Research Center using a 16-tow Electroimpact automated fiber placement machine.

High-performance reinforcements

Chomarat (Le Cheylard, France) will announce G-FLO, a reinforcement that combines structural and vacuum-draw functionalities, being used marine and wind energy applications. CHOMARAT has also received a JEC Innovation Award as a partner in the Fast RTM project, and will hold a preview launch of its new range of C-WEAVE Design carbon fabrics. G-FLOW is a two-in-one reinforcement for infusion processes that serves structural and vacuum-draw purposes. G-FLOW’s 100% glass composition helps maintain structural mechanical properties, while its original textile structure provides vacuum-draw properties. Chomarat says tests have demonstrated that for equivalent performance, there is an overall cost reduction of around 13% on average compared to a solution that requires an external flow medium.

The Fast RTM (resin transfer molding) project is sponsored by the IRT M2P technology research institute and brings in manufacturers, universities and technical centers. The Fast RTM project demonstrates the feasibility of using reactive RTM processes in the high-volume production of structural automotive parts. Under this project, CHOMARAT has developed optimized reinforcements that are compatible with the thermoplastic and thermoset resins used on the platform. The reinforcements are preformable, and suitable for high-speed processes and for the Fast RTM industrial platform. Entirely automated, the platform makes use of the compression resin transfer moulding (C-RTM) process.

Chomarat will also launch its C- WEAVE design, a range of carbon reinforcements designed for automotive and sports equipment. Two products are now available: a 100% carbon reinforcement (245 g/m2) and a hybrid carbon/Innegra reinforcement with impact strength and vibration damping properties, especially suitable in sports equipment.

Engineered yarns and fibers

Concordia Fibers (Coventry, RI, US) will offer its full line of engineered yarns and fibers for a range of technical fabrics. Concordia has developed much of its own machinery to convert a variety of fragile fibers, including unsized carbon fiber, bio-absorbable fibers and ceramic fibers. The two conversion processes most used are high-volume carbon twisting and commingling. Commingling is a process for producing highly flexible thermoplastic prepregs. Concordia’s process intimately blends unsized, continuous-filament carbon fiber with unsized, continuous-filament thermoplastic fibers to produce a yarn that can be woven or braided into fabrics. These commingled fabrics can then be molded into complex thermoplastic composite shapes or tubes when put under heat and pressure. www.concordiafibers.com

Decoring tools

Controx-Neuhäuser (Springfield, OH, US) will introduce its Decoring Cut tooling, which drills through honeycomb composite panels and undercuts the skins (thus removing the cores) in a single step. The company says a sophisticated end tooth design enables Decoring Cut to cut through the top skin while maintaining tight tolerances with no delamination. After the plunging operation, the tool interpolates to undercut the skins as deep as requested by aerospace industry norms. An aggressive diamond-shaped tooth design reportedly guarantees the removal and pulverization of the material without the “push back” of typical tooth designs. This saves the time required for manual core removal, tool changeout and machining. Available in solid carbide or HSS cobalt-powdered metal, Controx-Neuhäuser stocks the Decoring Cut in all industry-standard insert diameters, and in lengths so that standard 0.25-, 0.5- and 0.75-inch panel sizes can be accomplished in one pass. All Decoring Cut tools have a PVD multi-layer coating to enhance performance and service life.

Single-shot marine structure infusion

Core material supplier DIAB International AB (Laholm, Sweden) will emphasize it and Acquarius Shipyard (Goa, India) winning the ICERP-JEC Innovation Award within the marine segment for innovative use of a single-shot resin infusion process to fabricate stiffeners for hull and deck manufacture. Together, the two companies have worked to design and realise the 3D-infused boat in India for the first time. According to Aquarius Shipyard, multiple boat types can be infused using this process and it has won the shipyard a large number of government orders. The shipyard also says production of larger components has been made easier, VOC emissions are low, mold cycle times have been substantially shortened and there are high fiber fractions and good skin/core bonding. Organized by the FRP Institute every other year, ICERP is one of the most important events of the Indian composites industry.

Technical fabrics

Technical fabrics specialist Diatex SaS (Saint Genis Laval, Rhone Alpes, France) will emphasize its products for geotextiles, light aircraft, advanced textiles and composites, for use in products serving the aerospace, wind energy, filtration and personal protection markets. In 2015, Diatex bought back its weaving subsidiary (TDM) for €2 million, and then modernized it to bring it up to aerospace standards. In 2016, an aerospace certification resulted from these efforts. Diatex customers include Airbus, Boeing, Vestas and beneteau Group. The company is also an active participant in Industry Of the Future/TRANSPORT OF TOMORROW, through its involvement in the FUI Sealcoat project.

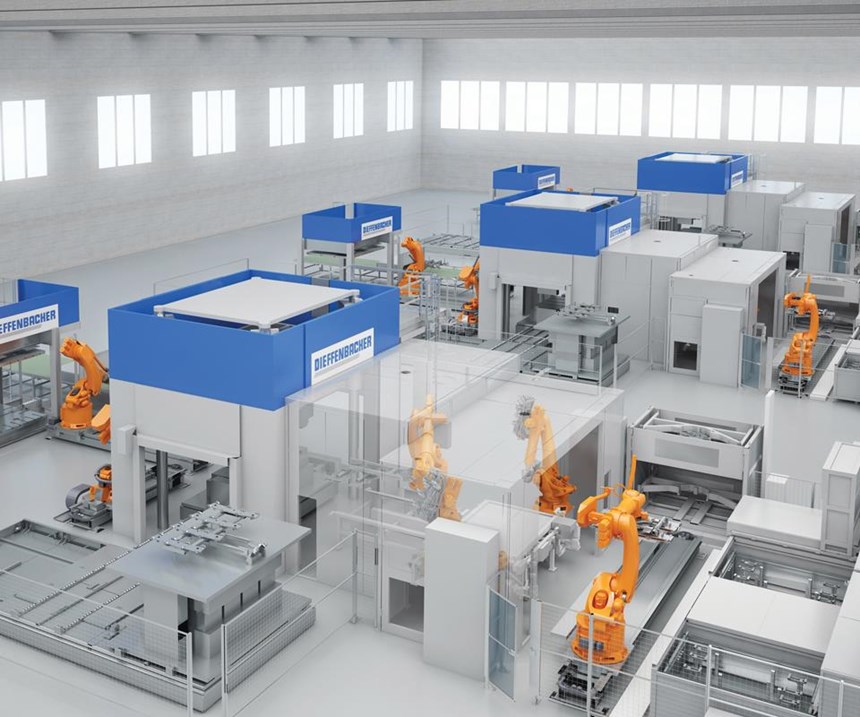

Preforming, compression molding machinery

Dieffenbacher (Windsor, ON, Canada) will focus on several technologies on its JEC World 2017 stand. Fiberforge, says the company, is the world's fastest tape laying system, enabling high-volume production of tailored, fiber-reinforced thermoplastic composites. Fiberforge creates at, net-shape engineered laminates from continuous glass or carbon fiber tapes. The system can handle up to four different tape materials in one production run. The complete production process is fully automated, including an automated spool-changing system that enables uninterrupted production.

Also in focus will be machinery for manufacturing multiple individual glass- and carbon-fiber 3D preforms, each in a single step. The preforms are then pressed into lightweight components with no additional joining process required. Dividing complex preforms into individual subpreforms reduces the level of complexity in production. With this technology, frame components can be manufactured with low material loss and with fiber orientation suited to the load path. This process is used in the manufacture of the roof of the Roding Roadster.

Focus also will be on wet molding, used to manufacture carbon fiber components with low 3D complexity, such as structural components — vehicle drive tunnels or reinforcements in the roof area — which must be able to withstand particularly high loads. For these components, wet molding offers a cost-effective alternative with a process chain that is easier to maintain. In contrast to resin transfer molding (RTM), the resin mixture in wet molding — usually epoxy — is applied to a dry carbon fiber fabric outside the press and then transferred into the press for molding. In the open process, the component is press-cured under pressure and temperature. Dieffenbacher also has developed the CompressLite press series, featuring easy automation, a high level of precision, good energy effciency and fast product changeover. www.dieffenbacher.com

Fast-cure epoxy intermediates

Dow Automotive Systems (Schwalbach, Germany) will present its latest VORAFUSE epoxy intermediates. VORAFUSE, says Dow, enables tack-free, room-temperature, shelf-stable pre-preg that can be handled, cut, stacked and preformed robotically. In the final compression molding step, the pre-preg is cured in approximately 2 minutes, leaving the remaining cycle time for tool movement, part ejection and reloading the next preform – without a required post cure.

In addition, ultrafast-cure VORAFORCE for RTM and wet compression processes and wet compression applications will be featured, enabling molding cycle times of <1 minute. Dow will put a special focus on related joining technologies such as BETAMATE and BETAFORCE structural adhesives. Dow Automotive will present a paper with Ford Motor Co. on March 16 at 12:00 pm on use of VORAFUSE in the Ford GT

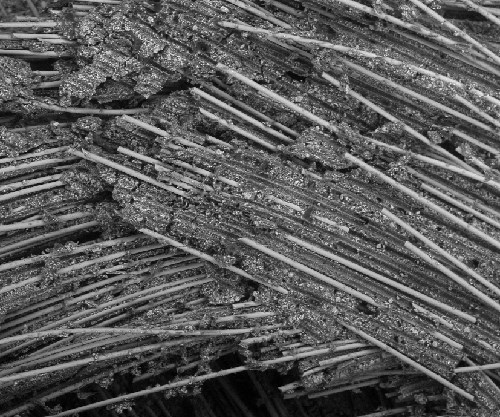

Recycled carbon fiber

ELG Carbon Fibre Ltd. (Coseley, UK), a manufacturer of recycled carbon fiber materials, is featuring its range of Carbiso products, designed to support lightweighting in high-volume applications in the automotive, rail and aerospace sectors. Carbiso M and TM isotropic mats offer good drapeability and performance while offering cost-effective weight reduction and significant environmental benefits compared to virgin carbon fiber.

Carbiso M mats are designed for closed mold processes and also can be used to manufacture intermediates, such as prepregs and sheet molding compounds (SMC) for composites manufacturing. Thermoplastic Carbiso TM mats are designed for fast-cycle press molding applications.

As part of the company’s ongoing expansion plan, ELG is manufacturing a range of extra-wide, nonwoven mats on a newly installed production line at its UK headquarters. The custom-built machine can produce a variety of materials, including 100% recycled carbon fiber mats and thermoplastic blends, such as carbon fiber commingled with PP, PA and PPS fibers. The mats are available in widths up to 2.7m in a range of fiber areal weights. www.elgcf.com

Rigid foam sheets, blocks and molded parts

General Plastics Mfg. Co. (Tacoma, WA, US) will feature its LAST-A-FOAM rigid and flexible foam series and build-to-print parts. Reported properties of LAST-A-FOAM include exceptional uniformity, consistent physical properties, high strength, durablility and versatility. Included is FST/OSU-compliant FR-3800 FST rigid foam, which can be thermoformed under specific conditions, is easy to machine and bonds securely with composite skins. This foam series, as well as two LAST-A-FOAM rigid foam product lines — FR-4700 for applications with peak temperature up to 400°F, and FR-6700, which complies with aerospace specifications — are also supplied as complex molded or cast parts. General Plastics says this rigid, self-skinning foam can be shaped based on customer requirements, with texture and color specified. Some aircraft interior applications include various panel configurations, decorative flyaway parts and replacement for aluminum parts. The company says non-aerospace customers may also benefit where applications require raw material cost reduction, lightweighting and cost savings for high-throughput parts.

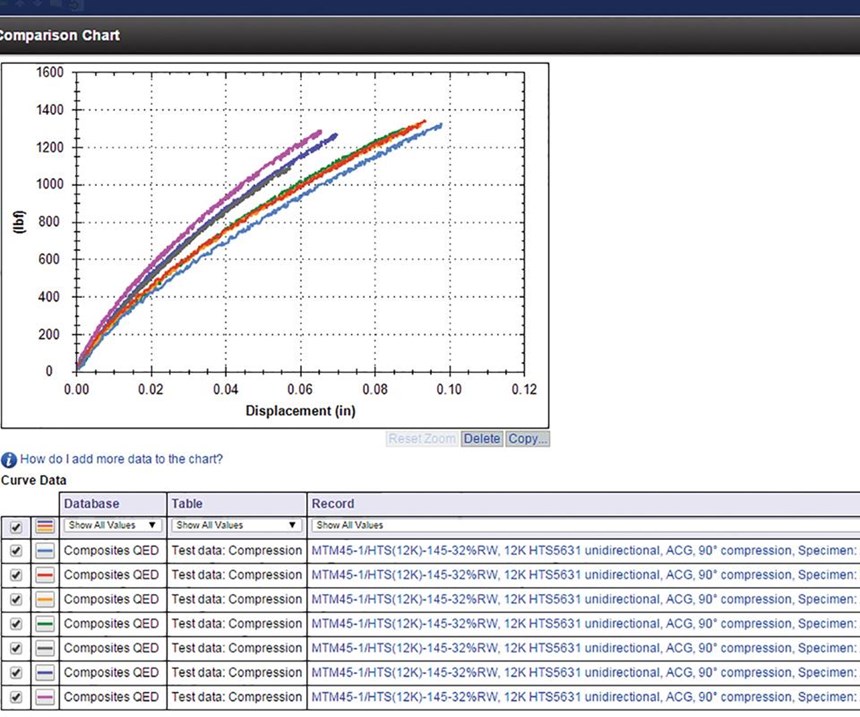

Materials data management software

Granta Design Ltd. (Cambridge, UK) will present at JEC World 2017 its latest software technology, solutions for managing materials data and support for the qualification and specification of composites. The GRANTA MI:Composites Package supports rigorous, auditable composites qualification and equivalency processes. It features reference data sources providing authoritative test and design data for composite materials. On Granta’s stand, attendees will learn:

-

Best-practice management of composite data, using the GRANTA MI Version 10 system (released December 2016), with a focus on new tools to ensure efficient materials data workflows and to enable digitalization of materials knowledge.

-

Granta’s Composite Qualification Package, which supports tasks, such as managing test series, and data import and analysis, and ensures a robust qualification process for highly-regulated markets, such as aerospace; equivalency studies are supported by reference data from authoritative sources, including NCAMP.

-

The new CES Selector 2017 software (released September 2016), which provides graphical tools to analyze the performance of composites relative to other materials.

-

Case studies of best practices in materials information management. Granta works closely with organizations that include Boeing, Honeywell Aerospace, Lockheed Martin and NASA, and as part of the Materials Data Management Consortium, to manage mission-critical materials data. This knowledge is embodied in the GRANTA MI materials information management system and is applied in many engineering companies. www.grantadesign.com

Oxidation ovens

Harper International (Buffalo, NY, US) is featuring advanced oxidation ovens in conventional and hybrid gas/electric designs with improved control and thermal uniformity for carbon fiber manufacture (photo #6, above). These systems, from research scale to production scale at 3-4m width, are said to offer increased availability with dual-utility option, faster start-up, reduced down time and the flexibility of selecting fuel based on current cost. The systems also allow the option of a universal plant, installable anywhere in the world to maximize efficiencies. Features include a proprietary design that enables consistent airflow within and outside of the tube while processing gasses. The primary air distributed inside of the tube is unaffected by the secondary air that circulates around the tube, maintaining thermal uniformity within the tube. The oven, says Harper, was designed to be easy and safe to use for new entrants into the marketplace. www.harperintl.com

Polyurethane composite spray molding

Hennecke Inc. (Sankt Augustin, Germany) will feature the application of its PUR-CSM (polyurethane composite spray molding) technology in sandwich load floor manufacturing for automotive applications. In particular, Hennecke will emphasize the PREG version of its PUR-CSM, in which a glass fiber mat is impregnated with polyurethane via active spray immediately before the molding process. The first large-scale application of PREG for exterior automotive components was the roof module for the new smart fortwo, as well as the roof module for the new Jeep Renegade.

Reinforcements, prepregs, compounds & core

Hexcel (Stamford, CT, US) will highlight its line of carbon fiber and composite materials, including fiber reinforcements, multiaxial fabrics, prepregs, adhesives, honeycombs, engineered core, molding compounds and tooling materials. Aerospace promotions will include advances in HiTape carbon fiber reinforcements for the automated layup of preforms for aircraft structures that are manufactured out-of-autoclave by resin infusion. Aerospace displays will include an Airbus (Toulouse, France) A320neo fan cowl for the LEAP 1A engine, made with Hexcel’s carbon fiber, structural prepreg, dry fabric and RTM6 resin. Hexcel also will show an engineered core part that demonstrates the company’s range of capabilities for transforming honeycomb into high-quality parts manufactured to very tight tolerances — Hexcel is opening an engineered core plant in Casablanca, Morocco, this year.

Beyond the aerospace sector, Hexcel’s promotions will focus on automotive technologies, including a suspension knuckle made by St. Jean Industries (Saint-Jean-d'Ardières, France) in which an aluminum structure is stiffened with Hexcel’s HexPly M77 prepreg stacks, resulting in a 26% stiffness increase compared to an aluminum-only knuckle, without an increase in part volume. The aluminum/CFRP hybrid version can be incorporated in the existing space restrictions, enabling the use of one-part design across all models in the range. The CFRP increases the part’s maximum strength-before-failure, with optimum load distribution determined by Hexcel’s FEM calculations. Hexcel produces the net-shape 2D preform in <1 minute. The knuckle’s prepreg stacks are bonded to the aluminum with Redux 677, Hexcel’s new fast-curing film adhesive for volume processing of metal/CFRP hybrid structures. Redux 677 is designed for automated compression molding and is said to be ideal for bonding metals, thermosets and thermoplastics with HexPly M77, Hexcel’s snap-cure prepreg for automotive structures.

Hexcel also will promote its Polyspeed Pultruded Carbon Profiles, new technology for pre-cured, thick-ply carbon fiber elements. They offer an economical structural reinforcement for wind turbine blades and any other industrial application that requires load-carrying performance. Hexcel says Polyspeed’s controlled resin and fiber content result in consistent quality, weight and mechanical properties, and enables very large parts with no restrictions on part length other than that imposed by transportability. At the show, Hexcel will display a 2m-diameter carbon laminate coil made with Polyspeed carbon fiber pultrusion for the structural reinforcement of a wind turbine blade.

Hexcel’s composite materials portfolio now includes HiMax multiaxial fabrics manufactured in Leicester, UK. Hexcel will display a composite floor demonstrator manufactured for Jaguar Land Rover, using HiMax carbon fiber multiaxial fabrics optimized for high-volume composites manufacturing processes. For this part, Hexcel created a non-crimp fabric that is said to balance drape, stability and permeability, using an automotive-grade, standard-modulus, high-tow-count carbon fiber. www.hexcel.com

Phenolic for rail, epoxy for automotive

Hexion Inc. (Columbus, OH, US) will introduce an ultralow free formaldehyde version (<0.1%) of its industry standard CELLOBOND J2027X phenolic resin for composite applications such as rail interior parts, which require very high flame resistant properties to meet stringent European fire safety standards. This product uses no styrene and is not a Class 1B-labeled raw material, and offers fabricators a means to produce EN45545 HL3-compliant panels with minimal product exposure concerns for production personnel.

Hexion will also introduce a new epoxy system for styrene-free, sheet molding compound (SMC) manufacturing of automotive composites. This new product extends the range of compression molding processes that Hexion supports beyond resin transfer molding (RTM), liquid compression molding (LCM) and prepreg molding.

Finally, also at Hexion: With the increasing length of wind turbine rotor blades, the resulting need for higher volumes of bonding paste, and the drive by wind composite manufacturers to shorten cycle times and reduce waste, the company has developed a new, larger packaging format called Hexi-Bag for its solid bonding paste. A Hexi-Bag contains five times more material than standard drums, saving shipping and inventory costs for customers and increasing supply chain efficiency.

High-performance resins, adhesives

Huntsman Advanced Materials (Switzerland) GmbH (Basel, Switzerland) will illustrate its range of high-performance solutions powered by ARALDITE-branded resin systems, components and adhesives. Featured on the stand will be an Expertise Gallery — a collection of products that highlight the significant contribution Huntsman high-performance chemistries are making as enablers of lightweight materials. Experts will be available to discuss product-specific applications and how the leading solutions can benefit key markets such as automotive, land transportation and aerospace. Huntsman will also sponsor the Aerospace Planet, designed to demonstrate composites’ key role in end-user innovation in the aerospace industry. The Planet will exhibit the latest technologies and products available for the market, as well as offer exclusive discussion and networking opportunities.

The Aerospace Planet will also host the Huntsman conference, "Composites in Aerospace Industry – Innovation Nowadays and Trends into the Future," Wednesday, March 15, 9:30 am-12:30 pm, where visitors will be invited to unearth business-relevant insights into the future of lightweight solutions in aeronautical applications.

Specialty reinforcement systems

METYX Composites (Istanbul, Turkey) is showcasing its latest high-performance E-glass, aramid and carbon fiber technical textile products in its range of RTM, multiaxial and woven fabrics, as well as promoting the expanded production capacity and kitting service for fabrics, cores and vacuum consumables now available from its factory in Hungary.

METYCORE FS (Fire Shield) and the latest new product development, METYCOREMAX FS (Fire Shield), are both fire-retardant RTM reinforcement fabrics, compatible with all major resin types. Another new product is METYX’s new range of "webbed" carbon fiber woven fabrics. These new product additions to the METYX product range for producing composite parts, combine higher mechanical performance with key processing benefits to meet the high productivity needs of manufactures in the automotive, transportation, marine, rail, wind energy and industrial markets.

Aimed primarily at the rail sector, METYCORE FS and METYCOREMAX FS are halogen-free, sandwich design, stitched-glass fabrics with a fire-retardant core. These additions to the METYCORE range of RTM reinforcements have been developed to meet the EN 45 545 fire standard, now the European cross-border rail industry standard for composites used in rolling stock. To validate the FR properties, laminates are tested at an EN-approved independent laboratory. The testing in progress covers all fire, smoke and toxicity (FST) aspects of the EN 45 545 fire safety regulation.

METYCORE FS and METYCOREMAX FS will be produced at the METYX plant in Istanbul, Turkey, available in the same published formats as traditional METYCORE RTM glass fabrics; customised fabrics with additional glass layers, surface veils and biaxial skins are also part of the product range.

The webbed carbon fiver woven fabric includes the addition of a fine layer of thermoplastic coating, which resembles a spider’s web, applied as a covering to the surface of the woven fabric. This addition stabilizes the woven fabric, making it less prone to deforming, which is a critical factor for a woven fabric during layup. The web coating, which is uniformly applied and varied according to the fabric areal weight, ensures the stabilization of fibers during the cutting process, which is said to result in clean cut and fringe-free fabric edges. Thanks to its elastic nature, the webbed carbon woven fabric has very good drapeability, essential for complex parts. It is also thermoformable, which qualifies the fabric for preforming processes.

Fiber sizings

Michelman (Cincinnati, OH, US) will feature its line of fiber sizings used by fiber producers and composite manufacturers to make composites stronger, lighter and more durable. Michelman’s flagship sizing brand, Hydrosize, is applied during the manufacturing process of chopped or continuous strand fiberglass, carbon fiber, natural fibers and fillers, or post-applied when making nonwovens and composite prepregs. Complementing Michelman’s line of fiber sizings are a selection of processing aids to provide fiber protection during forming, processing and post-processing, as well as slip resistance and lubricity.

Featured on Michelman’s stand in Paris will be new Hydrosize Link U470 and U480 fiber sizings designed to react with polyamide resin matrices. The enhanced reactive sizings are added during the fiber manufacturing process and become reactive during the compounding process. Hydrosize Link products are specialized polyurethane sizings that are said to improve composite performance in applications where materials are exposed to water, ethylene glycol and high temperatures.

Michelman also is featuring a portfolio of formulations that are shown to be compatible with previously sized recycled carbon fiber (typically reclaimed from epoxy) and that are also compatible with most common thermoplastic resins, such as PA, PP, PC and even high-temperature thermoplastics, such as PPS and PEEK. Examples are Hydrosize U-204, Hydrosize HP-302, Hydrosize PA845H or Hydrosize HP1632. www.michelman.com

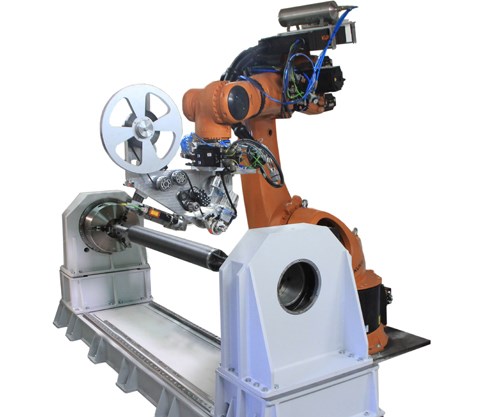

Thermoplastic/thermoset ATL/AFP head

Mikrosam (Prilep, Macedonia) will launch a new machine that integrates an AFP head for thermoset prepreg layup, and an ATL head for thermoplastic prepreg layup, into a single robotic cell for custom development of structural composites. Mikrosam says One of the greatest strength of the AFP/ATL Robot Machine solution is the capability for fast transition from automated placement of fibers to automated laying of tape and vice versa, by simply changing the head. Advanced parts can now be produced, whether flat or highly contoured, with automated computer controlled placement of the UD carbon (glass) — epoxy slit tape and thermoplastic prepreg tape, small to medium sized. The temperature control of the thermoplastic material is controlled via a compaction surface laser (heating temperature up to 400°C) integrated to the ATL head and an infrared heating method (heating the surface up to 100°C) with control provided for the thermoset material used by the AFP head.

The new AFP/ATL Robot solution machine was tested with prepregged material that was, slitted and rewound into wide and narrow slit tape spools, according to required tape dimensions by the customer. Mikrosam also designs and produces a prepreg making machines utilizing solvent, hot-melt and thermoplastic resin system.

Mikrosam controls the AFP/ATL process via its own tools: MikroPlace, intelligent machine-independent software for off-line programming, design, simulation and analysis; and MikroAutomate, software for process control and data acquisition tailored to the specific need of AFP/ATL production.

The new solution integrates the robotic arm, the two heads and the software combined with 24/7 online and offline technical assistance before and after delivery.

Thin-ply prepregs

North Thin Ply Technology (NTPT, Renens, Switzerland) will acquaint stand visitors with its range of Thin Ply Prepregs, processing technologies and products for performance sports. Launching at JEC World is its ThinPreg TP135 epoxy prepreg system. Developed in collaboration with the École Polytechnique Fédérale de Lausanne, TP135 offers reportedly excellent compression after impact (~300 MPa on a quasi-isotropic intermediate-modulus laminate) and excellent strength properties (first ply failure at >900 MPa for UD ThinPreg TP135 QI laminates with IM fiber). It is tailored for highly loaded applications such as aerospace, F1 and other autosport structural parts, where properties after impact are a key design driver.

Also new is NTPT’s composite tube manufacturing process for golf clubs. The company claims it offers a unique fiber placement capability that has enabled the first major technological development in golf shaft manufacturing since the mass adoption of graphite golf shafts in the 1980s. The fully automated tube-winding process is said to produce highly concentric carbon fiber shafts. Recently launched under the brand name TPT Golf at The Evian 2016, by professional golfer Lydia Ko, who used a TPT Golf driver shaft to win her silver medal at the Rio 2016 Olympics.

Visitors to the show will have an opportunity to see and feel the new TPT Golf shaft, and test it on a golfing simulator on the NTPT stand. Prizes will be awarded for “longest drive” and “nearest the pin.” www.thinplytechnology.com

Industrial Internet of Things technologies

Plataine (Waltham, MA, US), a provider of Industrial IoT (IIoT)-based intelligent automation software, will feature its Total Production Optimization (TPO) solutions to leverage IoT and artificial intelligence technologies, using sensor-enabled and mobility technologies to bring the world of IoT to advanced composites manufacturers. Plataine’s systems are designed to improve fabricators’ buy-to-fly ratios and become more competitive by increasing material utilization, improving productivity and reducing manufacturing cycles.

Also featured is Material & Asset Tracker (MAT), designed to address the challenges of composites manufacturing. MAT enables composites manufacturers to enhance production using IIoT-enabled automation software. Context-sensitive algorithms create ready-to-cut production plans integrated with existing infrastructure. MAT tracks asset location, manages material and assets shelf life, provides production status to management and customers, handles asset relationships and part genealogy, performs impact analysis when quality concerns arise, and traces assets’ history of events and quality information.

Finally, FabricOptimizer is software designed to help increase fabric use effciency. It optimizes based on real-time production data, automates ready-to-cut production plans, seamlessly integrates with existing IT systems and supports common geometry formats.

Plataine’s solutions are used by Tier 1 and Tier 2 suppliers, including CTC (an Airbus company), GE Aviation, Avcorp Industries, Composites Horizons, Hexcel, Israel Aerospace Industries (IAI), Triumph and MT Aerospace. Additionally, Plataine is a Siemens PLM Foundation Partner and a GE Digital (Predix) Partner. www.plataine.com

Prepregging, filament winding equipment

Roth Composite Machinery GmbH (Steffenberg, Germany) will feature its line of prepregging equipment, as well as its new prepreg laboratory. The lab offers customers and raw material producers the ability to experiment with new matrix systems, fibers and materials. Also featured will be Roth's range of filament winding machinery.

Composites testing services

R-Tech Materials (Port Talbot, UK) will feature its capabilities to test the mechanical, thermal and chemical properties of non-metallic materials, components and products for manufacturers and end users. These include plastics and fiber-reinforced composites for material approval and characterisation, to help identify quality issues, solve processing problems or identify why a product has failed.

R-Tech recently invested to expand its composites testing labs, which includes the first Zwick universal testing machine running on TestXpert III software in the UK. This investment has opened up the capability of testing materials at loads from 1N to 250 kN at -70 to 250°C, with thermal chambers provided by Severn Thermal Solutions. In addition, R-Tech's laboratories feature a state-of-the-art Hirox digital microscope and Zeiss scanning electron microscope with EDX micro-analysis for delivering failure investigation and characterisation solutions.

R-Tech is accredited to perform testing in tension, compression, flexure, shear and hardness to ISO and ASTM standards under controlled temperature and humidity conditions. Laminates can be prepared and samples machined in-house to customer requirements. The laboratories provide humidity, temperature and liquid chambers for sample conditioning.

The testing laboratories have the capability to test complex orientations to loads up to 1500 kN. Standard tests include lap shear, in-plane shear, climbing drum peel, shore hardness, compression of core materials and shear properties of sandwich panels, plus fatigue testing (in tension or in bending) at loads of up to 100 kN.

Reusable vacuum bags

Rubbercraft (Long Beach, CA, US) is showcasing its latest capabilities to design and custom manufacture elastomeric reusable vacuum bags (RVB), including large and complex shaped bags that can feature integrated breather layers to effectively prevent permeation and can be in direct contact with epoxy resin systems. The products are primarily aimed at aerospace and defense, wind energy and industrial markets where consistent quality is a critical factor. Rubbercraft says its RVB sheet production process and custom design service provides customers with a reliable reusable tooling solution. Overall, says Rubbercraft, this RVB system offers manufacturers a lower amortized tooling cost alternative to a disposable bagging system, especially for advanced composite parts needing compacting or debulking as part of a multiple ply molding process.

Rubbercraft provides a customised system solution, where the final RVB product supplied meets the specific needs of an individual component, custom designed and manufactured in sizes up to 20m² (215 ft²). Engineers from Rubbercraft’s technical team are involved from the start to ensure that the RVB compound materials used and sheet layering design specification matches customer needs in terms of heat and pressure processing parameters; any extra release coating requirements, such as FEP/ PTFE; the desired part surface finish and detail; the estimated number of pulls and overall longevity of the RVB to ensure financial payback. Software tools used include: Solidworks, CATIA, MasterCAM, Unigraphics, IGES, STEP, AutoCAD, and Pro-E.

Globally available adhesive solutions

SCIGRIP (Washington, UK), a global supplier of adhesives solutions, will show its range of specialty products that offer strength, durability and flexible cure times for large and small marine applications. SCIGRIP will present its portfolio of Lloyds Registry- and American Bureau of Shipping (ABS)-approved structural methacrylate adhesives (MMA). Following the company’s recent acquisition of Arjay Technologies, SCIGRIP also will showcase key Arjay products, including J-Core bonding compounds, radius compounds, multi-purpose vinyl ester and medium-weight bonding compounds.

In the spotlight will be SCIGRIP’s SG230 HV adhesive, which cures at room temperature and does not require elevated-temperature postcure. The system can be applied in thick-bead applications to achieve finished joints measuring >40 mm. SG230 HV also can be dispensed on vertical and sloped surfaces. The product’s adjustable open times provide manufacturers flexibility and offer a wide operating window. SG230HV requires no surface preparation, which eliminates the need to sand laminate parts, reducing labor costs and hazardous environmental dusts. www.scigrip.com

Resin systems and reinforcements

Scott Bader Company Ltd. (Wollaston, UK) will feature its material solutions, including high-performance polyester, vinyl ester and acrylic thermoset resins with compatible glass, carbon and aramid fiber reinforcements, Crestomer and Crestabond structural adhesives for bonding metal, plastic and composite substrates, as well as Scott Bader’s new zero-styrene gel coat. This latest gel coat technology innovation, already specified by a leading global wind turbine blade producer, will be launched at JEC World 2017 and offers a better alternative to Scott Bader’s existing Crystic Ecogel ultralow-styrene gel coat range, which was initially launched at JEC 2013.

Other products and services include the full range of FST (fire, smoke, and toxicity) filled resin and gel coated FRP laminate systems for hand layup, infused and pultruded parts, with all the fire standards passed and independent test certifications gained for a variety of rail, land transportation, marine and building applications. The company also will discuss an expanded GelTint volumetric gel coat color-tinting service with more local, approved supplies for European customers. www.scottbader.com

Bio-based epoxy resin systems

Sicomin Epoxy Systems (Marseille, France) is launching its InfuGreen 810 resin system for injection or infusion processing. A clear resin with a very low viscosity at standard room temperature with approximately 38% carbon content, InfuGreen 810 is derived from plant-based materials (ASTM D 6866) and is formulated with a choice of two hardeners, SD4770 and SD4771, suitable for small to very large components, including extremely thick laminates. Sicomin is conducting DNV-GL certification for SR InfuGreen 810.

Sicomin’s complete range of GreenPoxy bio-based products contain carbon contents ranging from 28-51%, said to be the highest on the market, tested in accordance with ASTM D 6866. The company also offers bio-based resins that can be used for hand laminating, infusion, pultrusion, filament winding and HP-RTM.

Top Clear, a new generation, ultra-fast coating formulation for clear carbon and other varnished components, is UV stable with very fast hardening and self-levelling characteristics. It provides a high gloss, translucent finish and can be applied by brush or spray on a range of substrates including glass, aramids, wood and carbon. It also can be used as a gel coat.

SR 1125 fire retardant system for infusion is a self-extinguishing fire retardant epoxy that can be used for infusion processes at room temperature. It features a low viscosity that ensures a steady, predictable and consistent resin flow. SR 1125 reportedly can pass through reinforcement fabrics without any filtering of the fire retardant components. www.sicomin.com

Technical fabrics

Sigmatex (Runcorn, Cheshire, UK) will feature its range of technical textiles for composites applications. On the stand at JEC Sigmatex will reveal one of Reebok CCM Hockey’s new 2017 sticks – SuperTacks 2.0. The stick uses sigmaST, Sigmatex’s spread tow carbon fibre and is designed to achieve maximum performance through lightweight, precision and strength. Sigmatex says sigmaST provides near-zero crimp, allowing for a thinner laminate than traditional 2D textiles. The company also reports that sigmaST provides improved coverage, making for a stronger stick capable of delivering a harder hit. Also featured will be the company's advanced woven solutions, 3D woven preforms, unidirectional reinforcements, spread tow materials, multiaxials and recycled fabrics.

Composites, foams, adhesives, films, tooling, consumables

Solvay Composite Materials (Brussels, Belgium) will present its advanced lightweighting material solutions for the manufacture of cost-efficient and high-performance structures for aerospace, automotive, mass transportation, oil and gas, and other industrial end-use applications. Products on exhibit will include thermoset and thermoplastic composites, structural foams, adhesives, composite matrix films, impact modifiers, tooling, and vacuum bagging consumables.

New products include:

- Flexible and efficient CFRP blanks for high-volume automotive body panel closures such as bonnets, wings and doors.

- TegraCore PPSU foams used as a structural foam core for lightweight sandwich assemblies in insulative and structural components for aircraft cabin and cargo interiors that require superior resistance to damage, fire and liquids (including Skydrol and water), and for use in structural parts manufactured using RTM processes.

- Liquid resin infusion technology for aerospace primary structure applications such as wing boxes.

- Ajedium high-performance films and laminates manufactured from a variety of engineering, aromatic and fluorine-based polymers. These lightweight and durable films may be mono- or multi-layer structures and meet stringent industry requirements regarding low permeability to water, as well as fire and burn-through resistance.

During the JEC World conference program, further insights into Solvay’s recent developments in thermoplastic composites will be shared by Marc Doyle, senior vice president research and innovation for Solvay Composite Materials. On Tuesday, March 14 at 10:00 a.m., Doyle opens the morning session dedicated to “Thermoplastics – Multimaterial Solutions” and will highlight how thermoplastic composites can address current and future needs in material selection and processing.

Doyle will also speak at the SAMPE Summit 17 Paris on Monday, March 13 during the session Block C - Advanced Materials, 2:00-3:30 p.m. Titled “Advanced Materials for Aerospace Solutions,” Solvay’s presentation will discuss the contribution of advanced materials in aerospace applications from the onset of composite technology to recent uses, and the future challenges composites need to meet to sustain the ever-expanding technology needs and opportunities for flight vehicles. Summit 17 Paris will take place in the roof-top restaurant of the Pullman Hotel Paris Tour Eiffel, just aside the Eiffel Tower.

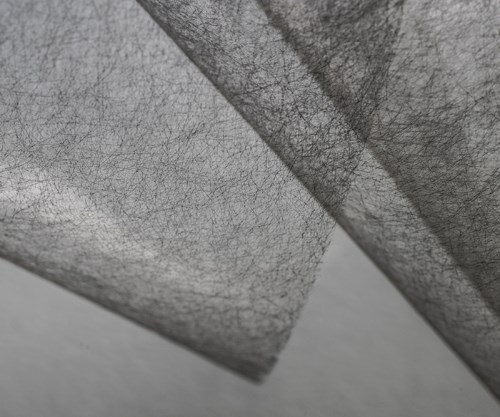

Nonwovens

Technical Fibre Products Inc. (TFP, Burneside, UK) will launch a range of lightweight nonwovens with increased flexibility, smoothness and fiber volume. These new materials have been compressed to deliver a higher density, reduced thickness and smaller pore structure for a given areal weight. They have been designed to give improved conformability when working with complex mold shapes and, due to the thinner structure, simultaneously improve the volume fraction achievable. The veil is available in a broad range of fibre types and areal weights in order to ensure the necessary functionality, compatibility and performance are achieved.

Other new products include a novel PTFE nonwoven and an extended range of lightweight thermoplastic veils. The PTFE veil is a new release material and offers a combination of hydrophobic and non-stick properties. The latest addition to TFP’s range of thermoplastic veils, which are designed to increase composite toughness, is also a high-performance veil and is made entirely from polyimide (fiber and binder). This new veil provides the advantage of chemical resistance combined with high thermal stability.

Typical applications for these nonwovens include enabling a high-quality surface finish, EMI shielding, conductivity, abrasion resistance and fire protection. TFP’s nonwovens also deliver composite interlaminar toughening, as well as an effective adhesive carrier, resin flow medium or galvanic corrosion barrier.

Thermoset and thermoplastic prepreg systems

TenCate Advanced Composites (Morgan Hill, CA, US) is highlighting several new thermoset and thermoplastic prepreg systems, along with a new thermoplastic composite application on the HP Spectre 13 Ultrabook, an ultra-thin — the world’s thinnest — laptop, which weighs only 1.1 kg/2.45 lb. Released in April 2016, the laptop features TenCate Cetex TC920 polycarbonate/ABS carbon fiber-reinforced thermoplastic composites for the bottom shell. Inherently fire retardant, TC920 meets UL-94 V0 standards without secondary FR fillers, and also is impact resistant. TenCate’s materials were selected to help achieve the lightweight, thin profile, and to dissipate heat when in operation on a user’s lap.

TenCate also is launching three new products. TenCate TC380 is a toughened epoxy with outstanding CAI properties of >40 ksi (276 MPa) and open hole compression strengths of >45 ksi (310 MPa). It achieves high OHC and high CAI strengths, and features a 28-day out-time, with a 21-day tack life to facilitate large assemblies.

New Cetex TC1225, a PAEK-based thermoplastic prepreg, has the structural properties of PEEK, but can be processed at temperatures 50-75°C below typical PEEK resins. TC1225 is available in carbon fiber-based UD tape, laminates and semipreg fabric formats. It is suitable for overmolding with PEEK, enabling part forming freedom and cost-effective detailed part consolidation.

Also new, TenCate E732 is a toughened epoxy prepreg designed for press molding applications. It cures in 4 minutes at 160°C/320°F and is suitable for high-volume industrial applications.

Finally, the AmberTool HXR series of tooling prepregs provides material and layup effciency by eliminating the need for orienting plies and by reducing the number of plies needed for lay up. www.tencateadvancedcomposites.com

Roving property testing

Textechno (Mönchengladbach, Germany), a designer and manufacturer of precision test equipment for fibers, yarns and rovings in textile and composite applications, will launch ROVINGTEST, which is designed to measure the most important properties of rovings all at once. ROVINGTEST can be used to characterize all yarns and rovings made from reinforcement fiberes such as carbon and glass. One important group of parameters assessed by ROVINGTEST are the friction properties of rovings to metal or ceramics and the existence or generation of broken filaments, e.g. due to the contact with surfaces. Moreover, the friction from roving to roving can be measured, which is an important parameter for instance as input for precise simulations of draping and forming processes. Spreading behaviour and homogeneity of filament orientation can also be measured by this system. ROVINGTEST is available to the market as a full testing system and as a service.

CNC centers, large-format additive manufacturing

Thermwood Corp. (Dale, IN, US) will feature its line of five-axis CNC machining centers for composites operations. These applications range from machining patterns and molds/plugs to trimming and machining finished parts.

Thermwood has also developed the Large Scale Additive Manufacturing (LSAM) system, which can perform the “additive” and “subtractive” functions on the same machine. This system uses a reinforced thermoplastic composite material to quickly create a part that is nearly, the final shape. A “subtractive” function then machines the part to the exact final net shape. Thermwood says its development system has performed well during initial additive testing and includes validation of an all new MeltShape Technology, which promises enhanced control of layer shape and improved bonding between layers. Thermwood says this new patent-pending approach uses one or more shaping wheels to shape, form and compress the hot plastic melt as it is being extruded, insuring that each new layer is the proper shape and thickness and that it bonds firmly to previously applied material. Thermwood says it plans to continue this development effort with the goal of offering these machines in a variety of large sizes for commercial applications.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More