Large portable antenna goes lightweight with conductive composites

CFRP matches metal performance at one-third the weight thanks to innovative materials and precision manufacturing.

Design Results:

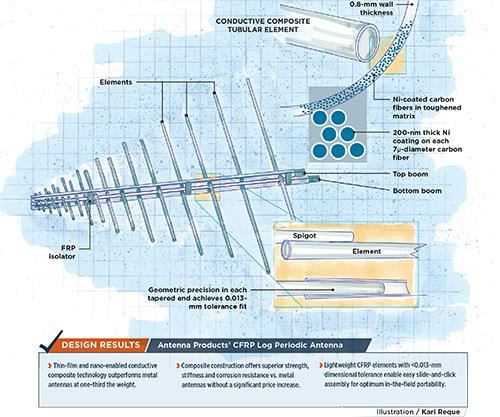

- Thin-film and nano-enabled conductive composite technology outperforms metal

- antennas at one-third the weight.

- Composite construction offers superior strength, stiffness and corrosion resistance vs. metal antennas without a significant price increase.

- Lightweight CFRP elements with <0.013-mm dimensional tolerance enable easy slide-and-click assembly for optimum in-the-field portability.

For decades, the peculiarities of tactical communications have posed a challenge in antenna design: The need for mobility and ease of installation suggest a small antenna size, but this compromises the performance required over a broad frequency range. Metal log periodic antennas developed in the 1950s at the University of Illinois (Urbana-Champaign, IL, US) offered the broad bandwidth necessary for tactical operations, and thus found widespread acceptance. These were, nevertheless, described in a 1988 US patent application as “unwieldy, difficult and time-consuming to deploy, and expensive.” A lightweight, inexpensive and easy-to-deploy alternative is finally available, thanks to a unique combination of conductive carbon fiber-reinforced plastic tubing and the materials, design and manufacturing expertise of three innovative companies.

Antenna ABCs

An antenna either receives radio frequency electromagnetic radiation from the air and converts it to alternating current (AC) for wired electrical devices, or converts AC signals to radio waves for transmission (aerial broadcast), or both.

The simplest, monopole antennas are basically electrified metal rods. Like those that protruded in years past from car hoods, they operate best in a narrow frequency range. Dipole antennas are two monopoles in opposition, arranged either in parallel or at an angle (e.g., “rabbit ear” TV antennas). Log periodic antennas, however, are more complex. They feature an array of dipole antennas, and look like fish skeletons. A central “spine” (boom) supports the “bones” (elements) arranged in pairs on opposite sides of the boom. The elements decrease in length from the array’s back to its front, each sized to target a discrete frequency range. The array is designed to provide smooth operation across a wide band of frequencies (hence the term broadband).

The more elements in an array, the higher its gain. Measured in decibels (dBi for antennas), gain describes how well an antenna converts electrical power into radio waves transmitted in a specific direction. An antenna with more elements would have more gain, but also would be longer, heavier and more difficult to deploy. Thus, antenna design is a balance — an attempt to achieve the most gain for the length and weight that best fits the application.

Large antenna goes lightweight

“With tactical antennas, the problem is weight,” explains Phil Park, VP sales at Antenna Products (APC, Mineral Wells, TX, US). “We already had a large aluminum antenna that customers really liked.” With a 5m-long boom, the TLP-20 aluminum structure is described as a rugged, transportable antenna, offering optimal communications in the 20-1000 MHz frequency range. “But now we can match its performance at less than half the weight,” says Park. “Instead of requiring two people to assemble and motivate it, now one person can easily do the job.” The next-generation, lightweight, conductive composite version, the TLP-20CC, weighs just 13 kg vs. its 40-kg aluminum predecessor. At one-third the weight, the composite antenna also opens up more deployment options. “We could put it on a push-up or pneumatic mast,” says Park, “and it doesn’t need the same weight of structure to support it now, so the boom and mast can be lighter as well.”

“The aluminum antenna is definitely harder to manipulate, even bowing in the middle a bit when you assemble it because of the weight,” Park comments. Here, the strength and stiffness of the carbon fiber-reinforced plastic (CFRP) is an advantage. It also increases resistance to wind and ice loading and makes the antenna corrosion-immune, even in aluminum-unfriendly seawater environments, extreme temperatures and other harsh conditions common to tactical operations.

Matching metal’s conductivity

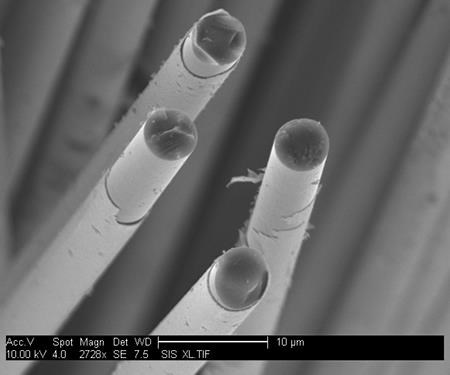

Lightweighting was the easy part. The design challenge was conductivity. Antennas must conduct electricity, hence their historically metal construction. “We’ve learned how to make the whole composite conductive,” says Conductive Composites’ (Heber City, UT, US) chief technical officer George Hansen. “We’ve reduced the dielectric contrast in the material’s x, y and z directions so that they are nearly all equally conductive. So it acts like metal.” He explains that the CFRP tubes used in the TLP-20CC comprise hundreds of thousands of carbon fibers, with each 7-micron diameter fiber surrounded by a nickel tube, thanks to the 200-nm thick coating imparted by Conductive Composites’ thin-film deposition technologies (see image above). “So now the metallic surface area in the composite goes out of sight.”

Although the resin used in this antenna is a typical 250°F/121°C epoxy, Hansen says his company’s processes are resin-agnostic. “We have made conductive composites using everything from wet layup epoxies to thermoplastic polyimides that cured at 316°C.” He adds, “The nickel coating adds ≈10% weight vs. a plain carbon fiber composite, but it increases conductivity by a factor of 50.” Nano-sized nickel filaments are added to the epoxy adhesives used to bond the conductive composites into structures.

Fishing for a precision fit

A potential problem, antenna assembly/disassembly and portability, found its solution in the event that inspired the project: Hansen’s son wanted to give his father a fishing rod made from the company’s Ni-coated carbon fiber and asked carbon fiber fishing rod pioneer Gary Loomis (North Fork Composites, Woodland, WA, US) to make it. While others admired the beauty and quality of the resulting three-piece fly rod, Hansen marveled at how strong, light and easy-to-assemble it was. High-quality rods are distinguished by the fact that they can be assembled and disassembled repeatedly throughout their lifetime without degradation.

“It practically shouted ‘antenna’ to me,” he recalls. The same would be required on the next-gen TLP-20CC. “The elements insert into the boom just like the sections of a fishing rod fit together or how tent poles fit together,” explains Hansen. “These must fit perfectly for the slide-and-click assembly to work,” he adds.

Loomis agreed the idea was promising and, after receiving positive feedback from antenna customers, the two began looking for an antenna manufacturer. Industry contacts suggested Antenna Products and development began.

Rolling a thin, strong tube

North Fork Composites is not only a composite tube supplier but also plays a key role in this product’s alchemy. “We’re well known for fishing rods,” says North Fork Composites CEO Alex Maslov, “but we also make deicing components for Delta Air Lines and conduit tubing for specialty applications.” He explains, “Just by putting Conductive Composites’ material through our process, we can make very light and stress-resistant elements vs. aluminum.”

That process begins with Conductive Composites’ thin-film deposition of nickel onto carbon fiber supplied by Hexcel (Stamford, CT, US). The coating can be tailored between 80-240 nm in thickness, depending on the conductivity required. The coated fiber is then prepregged by Patz Materials and Technologies (Benecia, CA, US) with a toughened epoxy resin. North Fork Composites then cuts the prepreg into patterns, which, when rolled, produce the ply orientations and thickness to achieve the desired mechanical properties. The patterns are tacked to a tapered steel mandrel and rolled using automated equipment. The rolled tubular blanks are shrink-wrapped and cured in a tall convection oven. The shrink-wrap is removed after cure, and the blanks are cut to lengths.

“Our machinery to process tubular composites is unique,” says Maslov, “with a singular focus on removing as much air as possible in order to prevent voids, resulting in very high strength. Our rod blanks are typically 60% lighter than anything else on the market.” He adds that this vastly increases design flexibility, making it possible, for example, to produce thinner wall structures without sacrificing strength. Hansen notes they’ve also avoided use of an electrically insulating glass scrim on the inside, which is common in other composite tube manufacturing processes.

The finished tubes are then sent to ATC, which assembles the antennas, adds the electrical components and electronics and tests the finished product. APC starts with two pultruded CFRP box tubes, one for the upper boom and one for the lower boom. One boom is positively charged and the other is negatively charged. They must be separated for the antenna to function, and thus are kept a fixed distance apart by fiberglass isolators glued across both booms. The joined boom assembly is then cut into three pieces for transport and field assembly. The elements, 60 total, are made from three diameters of tubing and arranged largest to smallest from rear to front of the antenna array. Slightly tapered at the ends, they fit onto tapered spigots that protrude from the boom assembly in a way similar to Loomis’ fishing rod sections.

Precision fit, high performance

The tolerance of the tapered ends is critical, and must be maintained at .002-.003 inch taper per running inch. “The tubes must locate onto the spigot every time within 1/8-inch, so that tolerance is 3 mils per inch,” explains Maslov. “So we are maintaining a tolerance of 1/3 mil in the way the elements fit together with the boom.”

“The ease of use with this antenna is incredible,” Park sums up, “which is a big plus during tactical deployments, for example, those used in emergency services. You want to set up and breakdown quickly.”

“Every antenna we’ve built so far has performed amazingly well,” agrees Hansen. “We started small and stepped up in size and power, little by little. At each stage … they have matched or beaten aluminum’s performance.”

APC is working with Vapor Shaft (Woodland, WA, US), the joint venture company formed by Conductive Composites and North Fork Composites, to develop a full line of log periodic, whip, yagi and sector antennas made using conductive composites for public- and private-sector applications, including search and rescue, disaster relief, law enforcement and collared wildlife tracking. Park goes back to the original driver for looking beyond conventional aluminum to realize the TLP20CC, “I handed the customer half of the antenna with one hand, and they were amazed because it’s so much lighter. It’s mind-boggling.”

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More