Machining update: One-shot dry drilling of stacked materials

Tool design innovations tighten tolerances and cut costs for those who drill composite-metal assemblies.

In the aircraft industry, where mechanical fastening of joined components is a necessity and the drilling of many thousands of holes per aircraft is, therefore, unavoidable, stacking the parts in joint position and drilling them in a single operation not only saves time, but also ensures proper hole alignment when fasteners are inserted. So-called one-shot drilling can produce a high-quality hole if all the joined parts are either all-metal or all-composite.

When carbon fiber-reinforced polymer (CFRP) and aluminum and/or titanium parts are stacked, however, the story is much different. Drilling composite/metal stacks, therefore, has usually involved multistep operations to permit the use of drill tools optimized for each material. This requires either tool changes or the use of multiple drill motors. Despite these precautions, poor-quality holes are still common. And in the best circumstances, all drilling, to date, has required minimum quantity lubricant (MQL) — minute amounts of high-quality lubricant applied, ideally, only at the cutting interface. This requires a method for controlled delivery of the lubricant, typically through channels inside the cutting tool. And that, in turn, increases the cost of an already costly drill tool and complicates the drilling process.

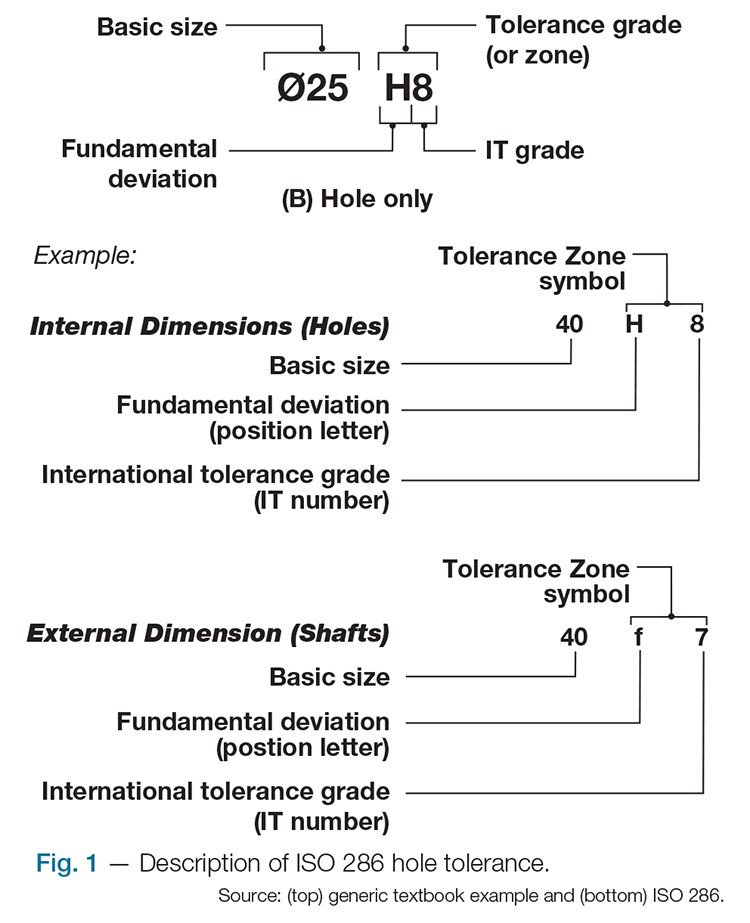

This was the state of the composite/metal stack drilling art until cutting tool manufacturer MAPAL Inc. (Aalen, Germany) developed a promising alternative: A simpler, one-shot, dry (yes, lubricant-free) drilling process for stacked materials that reportedly cuts tool cost by up to 50 percent, increases tool life by up to 200 percent and produces high-quality holes (specifically, H8 with a CPK of 2.4, see “Hole quality defined,” at the end of this article, or click on its title under "Editor's Picks").

Why dry drilling?

“MQL was developed to lower the buildup of material on the cutting tool and augment chip removal, but these are functions a good tool design should achieve,” contends Dr. Peter Mueller-Hummel, senior manager for Mapal’s aerospace and composites business unit, adding that lubricants hide shortfalls in tool capability. “We are using MQL to span gaps in tool performance.”

Mueller-Hummel, who has sought a dry drilling option since his career began, says the use of MQL compensates for some problems, but actually causes others. First, the lubricant actually wets carbon dust, keeping it in the hole rather than allowing the tool flutes to drive it out. “Often, too much oil is introduced into the tool’s airstream,” he adds, “causing significant overspray from the hole exits, to the point where jigs and even floors are slippery. OEMs then become concerned about contamination in the part, and cleaning is added as a secondary operation to machining.” Dry drilling eliminates all this, and eliminates the need to design lubricant channels into the tool.

“If you eliminate MQL,” he maintains, “you cut tool cost in half, right off the bat.” Further, MQL tools must be fashioned from special materials that, he argues, are not compatible with diamond-coating technologies. “Without MQL, we can use the best raw material, which enables complete chemical vapor deposition (CVD) coating of the tool with diamond, which extends tool life by a factor of two.” Mueller-Hummel also points out that the MQL system must be calibrated to ensure proper air and oil flow. The calibration process, he explains, “requires special training and must be completed before machining can begin. If the test fails, the whole system must be recalibrated.”

According to Mueller-Hummel, all of this time and expense can be eliminated by a shift to dry drilling. “One year ago, we started dry drilling with Bombardier on a wing application in Belfast [Northern Ireland],” he relates. With no necessity to deliver lubricant, drilling equipment could be simpler and less costly. “By eliminating MQL they could also use smaller, lighter drilling equipment, which is more reliable and requires less maintenance.” The result? He claims, “The cost per hole has been reduced by at least a factor of four, and the process has a higher CPK, with no jamming and sticking of wet carbon dust.”

Eliminating heat

In order to dry-drill H8 holes in composite-metal stacks in a single operation, the problems traditionally solved by using different tools, multiple drilling steps and lubricant had to be addressed in tool design and in control of drilling process parameters, specifically, rotational speed and feed rate. This required a fundamental understanding of the drilling processes for metals and composites.

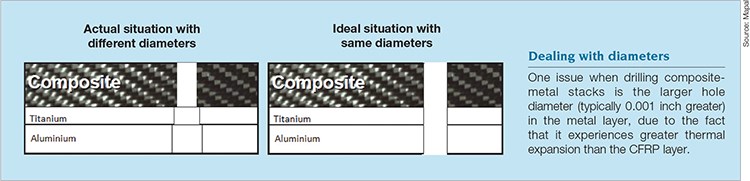

“The drill tool action to cut through composites vs. metals is very different,” says Mueller-Hummel. Developed before the advent of widespread use of composites, metal-drilling tools evolved from standard metals-cutting technology, where heat at the cutting interface actually melts the metal so that the tool can push through, similar to a hot knife through butter. “But that type of heat can damage composites,” he notes. And in stacked drilling the heat “causes the metal to expand.” The result is a larger hole diameter in the metal layer than in the composite layer. Thus, Mapal knew it must develop a tool geometry that works with metals at very low cutting temperatures.

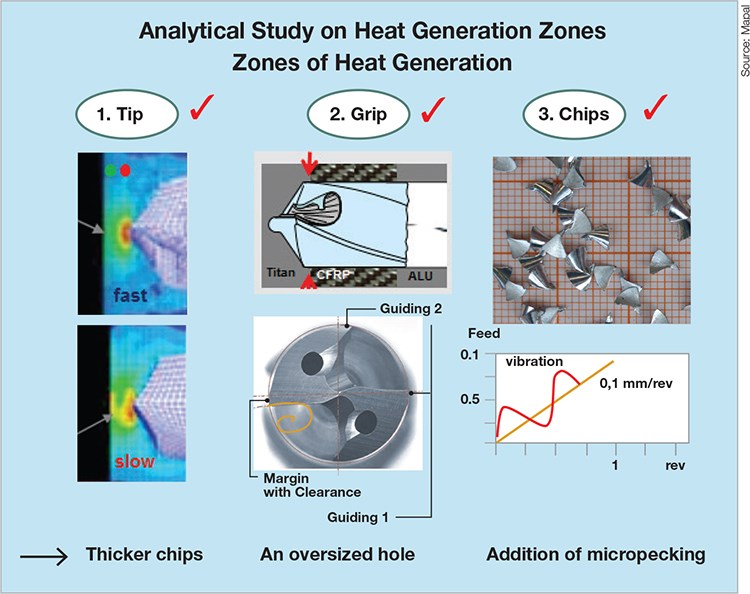

A fundamental study of drilling metals revealed three main locations where a drill tool generates heat: the tip (nose), the grip (edges/corners) and the chips (material removed from the hole). That stimulated the following developmental goals:

• The tip. Design a tip that could cut effectively at lower rotational speeds (100 m/min for CFRP, 120 m/min for aluminum) without melting the metal. “It was not easy to develop a tip which heats up only the relevant area and with the minimum heat required without transferring heat to the remaining tool body,” attests Mueller-Hummel. (See chart, at left.)

• The grip. Because the tool body reaches its highest speeds at its edges/corners, an increase in feed rate through the hole, to 0.1 mm/rev (.004 inch/rev), reduces the total length of time the tool is in contact with the material, and, thus, further limits heat transfer throughout the tool. Although changing the speed and feed rate might seem elementary, choosing a slower speed and a higher feed rate is the opposite of what is normally recommended for drilling of CFRP laminates.

• The chips. At a reduced RPM and higher feed rate, the tool cuts more deeply per revolution. “Now a problem arose in that this type of tool generates extra material, which has to go somewhere,” says Mueller-Hummel. “In traditional metal drill tools, when that buildup tries to squeeze the tool, the tool pushes that material into the hole edges, which, in effect, workhardens the edge and improves its fatigue life.” This does not apply in composites drilling, so excess material must be evacuated as soon as possible. A progressive flute design now helps to evacuate the chips. In addition, the chip size is reduced by means of a technique called micropecking: The drill motor is designed to alternately apply force and retract, many times per second. This action literally hammers the chips into smaller pieces (see "Hole Ambitions: Optimize! Customize!" under “Editor's Picks" at top right”).

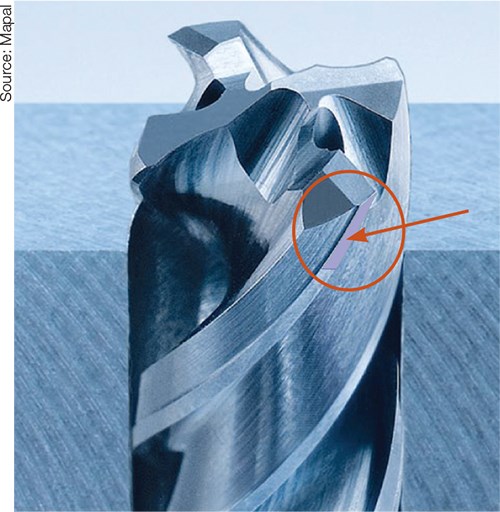

To handle the excess material buildup in the metal hole’s sidewall that results from the larger chips, Mapal employs an innovative single-blade reamer. “Normally, reamers have many blades, at least three to four,” Mueller-Hummel explains. “Ours has two guide pads and only one cutting edge.” By incorporating the single-blade reamer design into the drill tool, material that accumulates and puts a “squeeze” on the tool is removed — the guide pads move the material inward and then the reamer then cuts it off. “So we have refined the tool to perform a true cutting operation on its sides,” Mueller-Hummel summarizes. There is no “jamming” at the cutting edge and heat is further reduced.

Dealing with different diameters

One problem, however, still remained. When Mapal first started working with Bombardier, the aircraft manufacturer wanted to maintain H8 hole tolerance in stacked materials, but the metal hole was consistently 25µm (0.001-inch) larger in diameter than the composite hole (see drawing, at left).

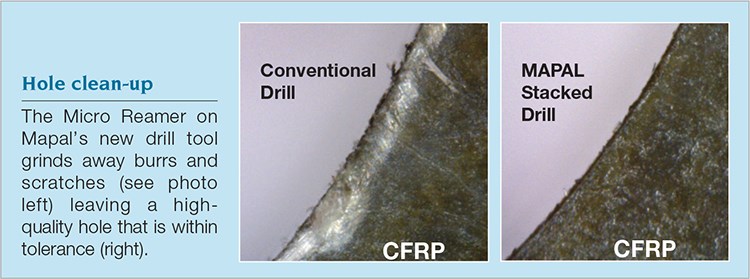

The solution was a second reamer. “Our idea was to put a microreamer on the drill tool,” Mueller-Hummel recalls. “By adding a small, very thin step of 10 µm to 50 µm [0.0004 inch to 0.002 inch], this additional cutting implement would only touch the composite and make its hole edge equal with that in the metal” (see photo at left). Now trademarked as the Micro Reamer, this feature also solves the chronic problem of “burring,” the term for the rough edge that remains on the composite after it has been drilled. In composites, the burrs or “hairs” remain because fibers aren’t sheared cleanly. Notably, as the drill turns, the heated matrix will “smear” and trap ragged fiber ends against the hole side. “At first, it appears this has worked like in metals,” he notes, “but after a couple of days, the fibers flex back into the hole and you have a smaller diameter. Everyone thinks this is a problem with composite materials. It is actually a problem with the drill tool design.”

The Micro Reamer is evenly CVD-coated so it works like a grinding tool, removing the uncut fiber. (See photos, at left).

At first, Mapal thought the Micro Reamer would only work when the composite was the first material in the stack, but after much study, found it doesn’t matter where the composite is because the hole diameters of the composite are consistently smaller than in the metal. Therefore, the Micro Reamer only removes encroaching fibers and burrs from the composite, and does not remove metal.

That said, the metal is most often positioned at the bottom of the drill stack as reinforcement for the composite structure. Metal chips that aren’t successfully evacuated can leave scratches (typically 1 mm deep) in the composite hole’s sidewall. Mueller-Hummel says, “This is no longer an issue because the Micro Reamer removes all of these scratches.”

Status and qualifications

Mapal has demonstrated that, at lower speeds and higher feed rates, the new drill tool can cut H8 holes in one shot, without MQL, for CFRP/CFRP and CFRP/aluminum stacks. “We can also drill H8 holes in CFRP/titanium and aluminum/CFRP/titanium stacks in a single operation, but,” Mueller-Hummel concedes, “we have to use MQL.” However, he adds that his team has developed a new tool that works with titanium and is now refining it to eliminate lubricant.

Nonetheless, Mapal’s tool design and drilling regime has achieved qualification at six OEMs and Tier 1 suppliers and is in the beginning stages with multiple others. And the potential for savings is significant. Mueller-Hummel reports, “We have another customer working on a large airframe drilling CFRP/aluminum stacks in four to five steps, requiring 30 minutes per hole and ending up with very poor quality. Our trials so far have reduced drill time to two minutes with an H8 quality in one shot and no MQL.”

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Optimizing, customizing composites hole drilling

Matching the drill tool to the job can save thousands of man-hours and millions of dollars.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpeg;maxWidth=150;quality=70)

.jpeg;maxWidth=400;quality=70)