Material equivalence testing in shared composites databases

In response to traditionally proprietary polymer matrix composites (PMC) qualifications, NCAMP continues its efforts to make material property databases publicly available.

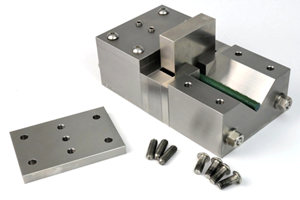

Photo Credit: Dan Adams

Compared to metals such as aluminum and steel, the number of stiffness and strength properties associated with polymer matrix composites (PMCs) is extensive. For metals, these mechanical properties are isotropic and thus assumed to be independent of material orientation. As a result, there are only two independent stiffness properties (tensile modulus and shear modulus) and only two independent strength properties (tensile strength and shear strength).

In contrast, the stiffness and strength properties for PMCs are directionally dependent, and therefore must be measured in three perpendicular orientations to fully characterize the material. A further complication is that the strength properties can be significantly different under tensile and compressive loading, and thus both tension and compression testing is required. A final complication is the dependence of some mechanical properties on environmental conditions, including temperature and humidity. Therefore, in addition to testing at room temperature/ambient conditions, PMCs are commonly tested at the extreme environmental conditions expected in service. For aircraft applications, this involves testing at -54ºC (cold) as well as between 71ºC and 121ºC following moisture conditioning (hot/wet). All of these considerations lead to large and expensive mechanical testing programs to fully characterize a PMC for use in aerospace applications.

Traditionally, these testing programs have been funded by large aerospace programs and test results have remained proprietary to the company that owns the program (e.g., Boeing, Airbus, Northrop Grumman, Lockheed Martin). Material producers typically provide significantly smaller sets of test data for their products, focusing on a limited number of stiffness and strength properties at room temperature/ambient conditions as well as the most severe environmental conditions expected for aerospace applications. Thus, the public availability of material property databases for PMCs has been very limited — until relatively recently.

In contrast to the aerospace industry, the design and analysis processes used for many non-aerospace PMC applications may not require generation of an extensive set of test results. The mechanical properties required in other markets for the design and analysis of composite structures depends on many factors, including the complexity of the structure, the role of analysis versus testing, as well as safety considerations and governing regulations. For any application, however, the use of numerical analysis, such as finite element analysis (FEA), typically requires a complete set of material stiffness properties as well as a variety of strength properties to predict the various modes of composite failure in the structure. As a result, comprehensive material datasets are of interest for many industries using composites.

Currently, more than 25 PMCs are included in the NCAMP database, with a focus on materials for use in the aerospace industry.

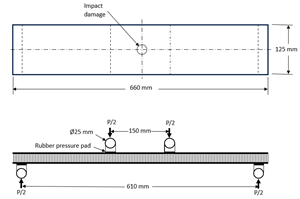

For more than 25 years, efforts have been ongoing to create a publicly available material property database for PMCs. The Advanced General Aviation Transport Experiment (AGATE) program, begun in 1995, focused on the material characterization of PMCs for use in the general aviation industry. AGATE was followed in 2005 by the National Center for Advanced Materials Performance (NCAMP), which started as an FAA-funded program within the National Institute for Aviation Research (NIAR) at Wichita State University (Kan., U.S.). NCAMP has since become a self-sustaining national center, in partnership with the FAA, CMH-17 and industry to produce a database for PMCs that is publicly available. Included for each material system in the NCAMP database are lamina-level stiffness and strength properties, and limited laminate-level material properties from unnotched tension and compression testing, open-hole and filled-hole tension and compression testing, and compression-after-impact testing. Additional physical test results include density, cured-ply thickness, fiber and resin volume fractions and glass transition temperature (Tg). Currently, more than 25 PMCs are included in the NCAMP database1, with a focus on materials for use in the aerospace industry.

The database entails a final difference between testing requirements for PMCs versus metals: finished PMC material properties vary according to the fabrication process used. Unlike metals, PMCs are advanced to their final state by further processing input materials, such as dry fiber reinforcements and liquid resin or uncured composite prepreg. As a result, final mechanical properties depend on the layup method, molding technique and cure process used during fabrication. Examples of relatively minor fabrication variations that may affect mechanical properties include minor changes in the fiber or matrix materials, their volume fractions or their manufacturing processes, as well as slight differences in layup, molding or cure processes.

This material property dependence on processing differs from what is often experienced with metals. For example, the mechanical properties of commercially available aluminum alloys are readily available and are not expected to be affected by component fabrication from purchased material stock. Thus, for many aerospace applications, an additional step, referred to as material equivalence testing, is required to determine whether the properties of the PMC part resulting from the manufacturer’s fabrication method are equivalent to those for which the dataset was developed.

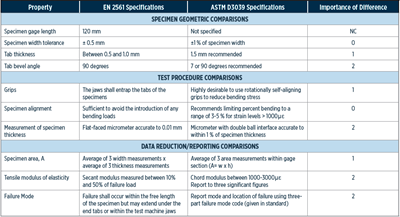

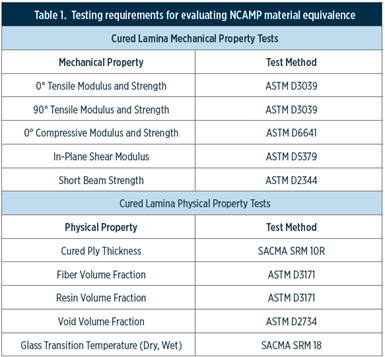

The objective of material equivalence testing is to perform limited testing and evaluate selected material properties to demonstrate that laminates created by the part manufacturer will have the same properties as the material property dataset used for structural analysis. The material properties to be used for evaluating material equivalence have been selected based on their ability to detect changes in the fiber and matrix materials, the prepreg manufacturing process, the layup method and the curing process. Table 1 lists the material properties and associated test methods used by NCAMP for demonstrating material equivalency. Additional information regarding the NCAMP equivalency testing process is available in References 2 and 3.

Finally, note that all of the testing discussed above is associated with the coupon-level testing located at the base of the building block pyramid that I discussed in my August 2021 column and December 2021 column. This coupon-level equivalence testing enables the use of the NCAMP dataset for structural analysis of parts fabricated using the material. Note, however, that demonstrating material equivalency at the coupon testing level does not imply material equivalence with the NCAMP material at the higher element and subcomponent levels of the building block pyramid. Therefore, to substantiate structures for certification at these higher building block levels, additional testing using more complex test articles at the element and subcomponent level also may be required.

References

1National Center for Advanced Materials Performance (NCAMP), https://www.wichita.edu/industry_and_defense/NIAR/Research/ncamp.php

2“Composite Materials Handbook - 17 (CMH-17), Volume 1-Revision H: Guidelines for Characterization of Structural Materials,” SAE International, 2022, Section 2.8.

3Ng, Y.C. and Tomblin, J.S., “NCAMP Standard Operating Procedures (SOP),” NSP 100 Rev G, March 2017, https://www.wichita.edu/industry_and_defense/NIAR/Documents/NCAMP/NSP100NCAMPStandardOperatingProcedureMarch272017RevG.PDF

Related Content

Crashworthiness testing of composites: A building block approach, Part 2

Following the previously discussed coupon-level testing element, subcomponent and component testing are the next steps in designing crashworthy composite structures.

Read MoreDamage tolerance testing of sandwich composites: The sandwich flexure-after-impact (FAI) test

A second new ASTM-standardized test method assesses the damage tolerance of sandwich composites under flexural loading.

Read MoreCrashworthiness testing of composites: A building block approach, Part 1

Determining the crashworthiness of composite structures requires several levels of testing and analysis, starting with coupon-level crush testing.

Read MoreComposite test methods (and specifications) for fiber-reinforced concrete structures

While initially focused on transitioning existing standards published by the American Concrete Institute, the relatively new ASTM Subcommittee D30.10 is developing new standardized test methods and material specifications for FRP composites.

Read MoreRead Next

Determining the equivalency of composite test methods

While time consuming and somewhat subjective, the comparative assessment approach has been proven effective toward assessing composites test method equivalence.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More