Determining the equivalency of composite test methods

While time consuming and somewhat subjective, the comparative assessment approach has been proven effective toward assessing composites test method equivalence.

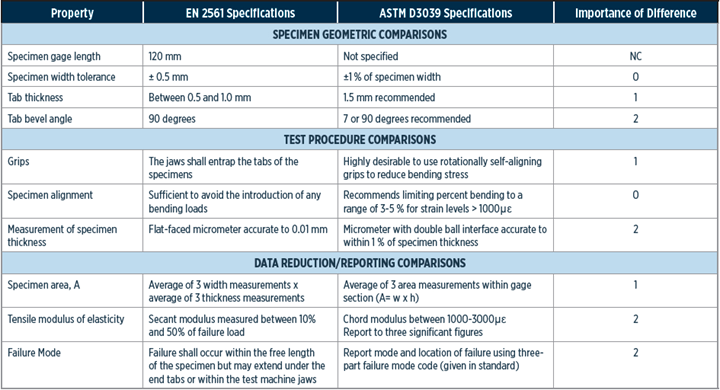

Fig. 1. Examples from comparative assessment tables for 0° unidirectional tensile testing. Photo Credit: Dan Adams

Among the first decisions to be made when initiating a composites testing program is the selection of test methods to follow. Unless performing highly customized testing, it’s usually not difficult to find a standardized test method for measuring virtually any mechanical property of a composite material. However, choosing which standardized test method to follow may be more difficult.

For starters, within a formal standards organization such as ASTM International (West Conshohocken, Penn., U.S.), there may be multiple test methods available for measuring the same material property. For example, there are two ASTM compression test methods (ASTM D34101 and ASTM D66412) and three in-plane shear test methods (D35183, D53794 and D70785).

Additionally, there are several standards organizations that publish a series of test methods for measuring mechanical properties of composites. This includes two international formal standards organizations, ASTM International and the International Organization for Standardization (ISO, Geneva, Switzerland); regional standards organizations such as the European Committee for Standardization (CEN, Brussels, Belgium); national organizations such as the Japanese Standards Association (JSA, Tokyo, Japan); and consortiums like the Suppliers for Advanced Composite Materials Association (SACMA). Finally, major aerospace companies such as the Boeing Co. (BSS standards, Chicago, Ill., U.S.) and Airbus (AITM standards, Toulouse, France) have their own series of test methods. As a result, there are multiple standardized test methodologies available for measuring the mechanical properties of composites. Thus, if test standards are not specified, it can be difficult to choose which one to follow.

Test methodologies from the most widely used standards organizations, including ASTM, ISO and CEN, are often similar, but are rarely, if ever, identical. This leads to questions regarding the significance of identified differences and whether the standards will produce equivalent test results. One method of assessing equivalence is to perform comparative testing, carefully following each of the test methods and evaluating the test results. However, performing a separate test program to investigate candidate test methods is rarely an option

By better understanding the differences that exist between standardized test methods used to measure the same material properties, it’s possible to begin addressing how best to reconcile the differences between standards.

To evaluate equivalence, a detailed comparison of all aspects of each test method must be performed and the significance of all identified differences must be assessed. In some cases, these assessments are not difficult. For example, the difference between using 6 versus 6.35-millimeter (0.25-inch) diameter loading cylinders when performing flexure testing is insignificant and would not be expected to affect test results. Some differences, however, are more difficult to assess. For example, a difference in the gage length of a compression specimen may have a significant effect on the measured compression strength due to the possibility of bending or buckling prior to compression failure. Additionally, there are cases in which a detail is not specified in one of the test methods, leaving options available that could produce significant differences in test results.

The assessments of such differences are subjective, as they are based on an evaluator’s knowledge, testing experience and even their intuition. This is something I learned from leading one of the only comparative evaluations published, an FAA-supported study from 2002-2003

This study resulted from an earlier composite material characterization program performed using primarily CEN test methods. The test results and statistical data were later submitted to CMH-17 for inclusion in the Composite Materials Handbook7. Since this handbook specifies that ASTM test methods are to be followed, a review of the CEN and ASTM test methods was performed by a CMH-17 committee. The two sets of test methods were found to differ in several aspects and were not expected to produce equivalent results. This outcome led to the detailed assessment of equivalence as described in this column.

The process began by performing a detailed comparative evaluation of each test method. Results were arranged into three comparison tables, focusing on:

- Geometric features, including important dimensions and tolerances of both the specimen and test fixture.

- The test procedure, including specimen preparation and instrumentation, procedures for specimen preconditioning, loading and testing as well as accuracy requirements for measured quantities.

- Data reduction and reporting, including procedures, formulas and statistical methods used to calculate and report test quantities.

In addition to listing specific parameters associated with each of the test methods reviewed, the significance of differences in parameters was assessed and included in the comparison tables. For every parameter compared, the equivalence assessment was made using the following rating scale:

0 - No difference, essentially the same, not expected to produce any effect on results.

1 - Insignificant difference, potential to produce insignificant effect on results.

2 - Minimal difference, difference of minimal significance, potential to produce minimal effect on results.

3 - Moderate difference, difference of moderate significance, potential to produce moderate effect on results.

4 - Major difference, difference of major significance, potential to produce major effect on results.

For cases where an assessment of equivalence was not possible, a rating of NC (not comparable) was used. A few examples from each of the three comparison tables for lamina tensile testing (0° unidirectional) have been compiled in Fig. 1. Of the 16 types of tests investigated, four were identified as requiring follow-on testing in a second round of the investigation to assess equivalence8. Following this review and discussion, a brief summary of each test method comparison was provided, which emphasized the most significant differences between the test methods.

While this comparative assessment approach is time consuming and somewhat subjective, it has been demonstrated to be an effective step towards assessing test method equivalence. If the assessment of specific test parameters are difficult to

References

1ASTM D3410/D3410M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading,” ASTM International (W. Conshohocken, Pa., U.S.), 2016 (first issued in 1975).

2ASTM D6641/D6641M-16, “Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture,” ASTM International, 2016 (first issued in 2001).

3ASTM D3518/D3518M-18, “Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate,” ASTM International, 2018 (first issued in 1994).

4ASTM D5379/D537M-19, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method,” ASTM International, 2019 (first issued in 1993).

5ASTM D7078/D7078M-20, “Standard Test Method for Shear Properties of Composite Materials by the V-Notched Rail Shear Method,” ASTM International, 2020 (first issued in 2005).

6Adams D.O. A Comparison of CEN and ASTM Test Methods for Composite Materials. Technical Report, U.S. Department of Transportation. Report no. DOT/FAA/AR-04/24, June 2004. Washington DC: Federal Aviation Administration.

7Composite Materials Handbook (CMH-17), Volume 2: Material Properties, SAE International, Rev. G, published 2018.

8Adams D.O. Comparative Testing to Assess the Equivalence of CEN and ASTM Test Methods for Composite Materials. Technical Report, U.S. Department of Transportation. Report no. DOT/FAA/AR-04/50, February 2005. Washington DC: Federal Aviation Administration.

Related Content

Testing to support composite bolted joint analysis

An overview of ASTM Standard Guide D8509, and its coupon-level mechanical testing of design properties for analyzing composite bolted joints.

Read MoreInterlaminar tensile testing of composites: An update

New test method developments for measuring interlaminar tensile strength address difficulties associated with the ASTM D6415 curved beam flexure and ASTM D7291 flatwise tensile tests.

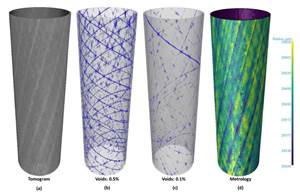

Read MoreMulti-scale 3D CT imaging enables digital twinning, high-fidelity simulation of composite structures

Computed tomography (CT) provides highly accurate 3D analysis of internal microstructure, performance simulation of carbon fiber/PEEK satellite strut.

Read MoreCrashworthiness testing of composites: A building block approach, Part 2

Following the previously discussed coupon-level testing element, subcomponent and component testing are the next steps in designing crashworthy composite structures.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More