Microwave: An alternative to the autoclave?

Aerospace composites manufacturer GKN evaluates microwave oven practicality and cost-effectiveness.

Autoclave curing of composite structures has been such a staple of high-performance composites industry practice that it’s difficult to imagine aerospace-grade composites manufacturing without it. But the desire to move part cure out of the autoclave is pronounced, thanks primarily to the autoclave’s strong appetite for energy and time, neither of which is in abundance in today’s manufacturing environment. Out-of-autoclave thermosets, as well as thermoplastics, increasingly offer viable alternatives to autoclave-cured thermosets. Oven curing is getting more attention of late, but there is another way out of the autoclave that also is getting closer scrutiny: microwave curing.

This is what GKN Aerospace (Isle of Wight, U.K.) had in mind in October 2009 when it acquired a Hephaistos microwave curing oven from heating systems specialist Vötsch Industrietechnik GmbH (Reiskirchen-Lindenstruth, Germany). Although it was developed at the Karlsruhe Institute of Technology (Eggenstein-Leopoldshafen, Germany), the microwave curing process was commercialized subsequently by Vötsch.

John Cornforth, VP of technology at GKN Aerospace, says the company’s goal for the microwave effort was to test the machine’s capability and give GKN a better understanding of how microwave heating differs from autoclave heating by curing several parts in the oven.

In conventional or surface-heating systems, such as those found in autoclaves, a composite part heats from the outside in, as heat energy is transferred through the part’s thickness. The process duration is determined by the rate of heat flow into the composite structure. The flow rate depends on the material’s specific heat, thermal conductivity, density and viscosity. As a result, the edges and corners of the part achieve the set point temperature before the center does. The part also heats at an uneven rate, which can stress the finished product. Therefore, the temperature in an autoclave and a conventional oven must be ramped up and down slowly to minimize part stress, a factor that makes overall temperature control a challenge.

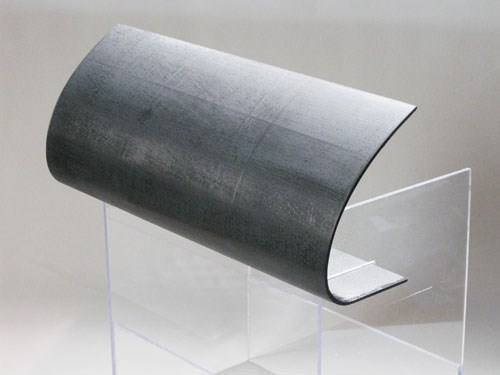

Conversely, microwave technology relies on volumetric heating. Heat energy is transferred electromagnetically and relatively evenly and quickly throughout the part, but not as a thermal heat flux. This enables better process temperature control and less overall energy use, and results in shorter cure cycles. It also enables the processor to direct heat specifically toward the part to be cured, thus maximizing the curing process efficiency.

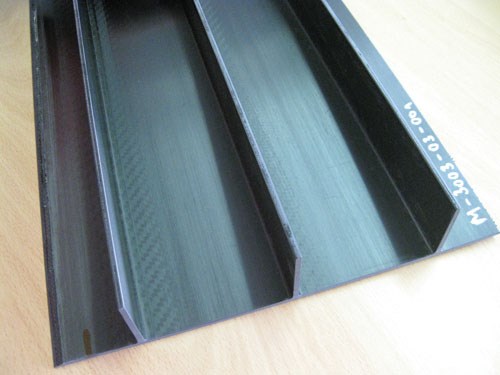

Cornforth says the Hephaistos oven is 1.8m/5.9 ft in diameter and 3m/10 ft long and offers a maximum temperature of 400°C/752°F. It was delivered in early 2010 and commissioned later that year. Since then, GKN has worked with the oven experimentally, evaluating processes and quality control by curing several 4- to 5-mm (0.16- to 0.20-inch) thick stiffened skin structures for aircraft wing flaps. Three out-of-autoclave pregregs were evaluated: MTM-44-1 from Advanced Composites Group (Heanor, Derbyshire, U.K.), M56 from Hexcel (Stamford, Conn.) and Cycom 5320 from Cytec Engineered Materials (Tempe, Ariz.).

The primary question GKN is attempting to answer is this: Is it possible to replicate autoclave cure quality in less time, using less energy? So far, says Cornforth, the results are promising. GKN’s experience to date shows that microwave technology consumes about 80 percent less energy than a comparable autoclave, with a 40 percent savings in cycle time. The total cycle time was 4.5 hours at a part set point temperature of 180°C/356°F and a tooling temperature of about 80°C/176°F. Pressure in the oven, says Cornforth, was about 100 psi/6.89 bar.

The shorter cycle is possible because the microwave oven requires minimal ramp-up to setpoint temperature and the process has less tooling-driven thermal lag. Further, when cure is complete and the oven shuts off, there is no cool-down of the oven itself. Like a microwave oven for domestic use, it heats only certain nonmetallic materials, thus the oven is always cool to the touch.

The difference in part and tooling temperature is an important distinction. An oven or autoclave, by its nature, applies the same heat uniformly to all structures — parts and tools. In a microwave system, material composition has an impact on temperature. Metals are reflective to microwaves and thus do not heat up. Certain nonmetallic materials, such as tooling epoxy, are reactive and do heat up. Additionally, there are some nonmetallic materials that do not heat up because they are transparent. By use of specific material combinations, it’s possible to make some parts of the tool — areas not in contact with the component — reflective to microwaves; conversely, it’s possible to make tooling surfaces reactive to microwaves. This is what allows the tool temperature to be held lower than the part temperature.The tooling GKN used in its analysis, says Cornforth, consists of an Invar base with a carbon fiber laminate surface. “We wanted a tool base that has no coupling [with the microwaves], but with a coating that does couple with the microwaves,” he says. “We don’t want a cold tool and a hot part, but we don’t want to heat the whole tool.”

Reiner Wiesehöfer, a principal at Vötsch, says adapting microwave curing requires an understanding of how microwaves function to make the process viable for curing. “You can’t take a microwave oven and simply apply the same process and parameters as you used in the autoclave. You must create a process that is suitable to the microwave.”

A key to such adaptation, says Wiesehöfer, is use of thermocouples on the part and the tool to monitor process temperature. This is necessary because the air and oven walls are not heated, thus temperature must be measured where heating actually occurs. Further, because the process measures the temperature of the composite part, says Wiesehöfer, it’s possible to manipulate temperature in sections of the part. For instance, if the user wants to reduce temperature in a region, shielding can be applied to make the area reflect microwaves, thus shielding the uncured laminate.

Of course, microwave heating is not confined to the part and tool. Consumables — breather cloths, bagging mats and sealant material — react to microwaves and, Cornforth notes, one of the challenges GKN has faced is that each material absorbs microwave energy differently. “How do consumables behave?” Cornforth asks rhetorically. “If they don’t behave the way you like,” he says, “you have to find materials that are better adapted to the process.”

GKN has several finished parts now, says Cornforth, and the company is in the process of doing differential scanning calorimetry (DSC) analysis, nondestructive testing and microscopic evaluation of cut-ups to assess part quality. The parts will be compared to identical parts produced via autoclave. He adds that GKN Aerospace is working to Airbus specifications to benchmark the quality of the microwave-cured composite laminate. Initial results clearly demonstrate that microwave-cured composites achieve the required quality of an autoclave cure.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More