Precision design for deployable space structures

Enabling SMAP mission success, unprecedented design requirements were deftly managed using composites in the largest unfurling and rotating reflector to date.

Share

Read Next

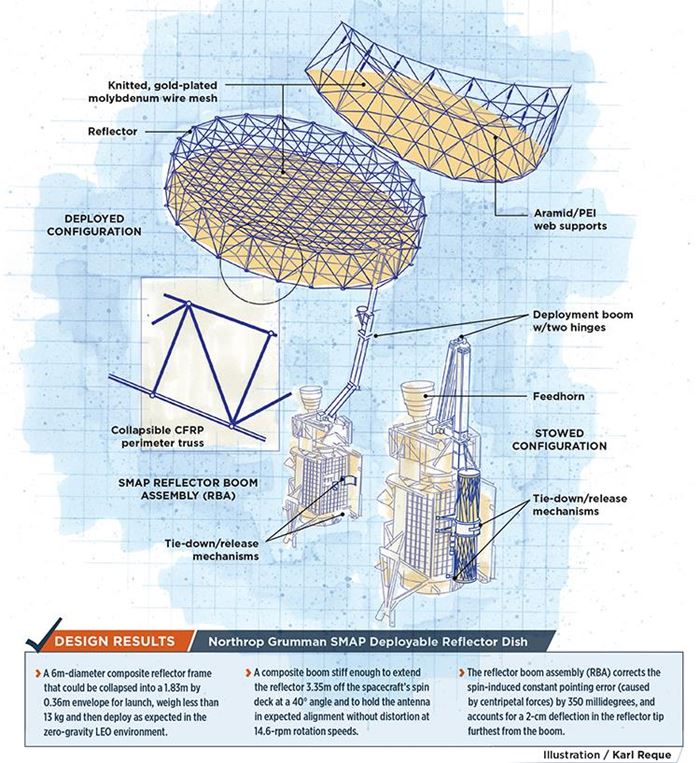

Design Results:

- A 6m-diameter composite reflector frame that could be collapsed into a 1.83m by 0.36m envelope for launch, weigh less than 13 kg and then deploy as expected in the zero-gravity LEO environment.

- A composite boom stiff enough to extend the reflector 3.35m off the spacecraft’s spin deck at a 40° angle and to hold the antenna in expected alignment without distortion at 14.6-rpm rotation speeds.

- The reflector boom assembly (RBA) corrects the spin-induced constant pointing error (caused by centripetal forces) by 350 millidegrees, and accounts for a 2-cm deflection in the reflector tip furthest from the boom.

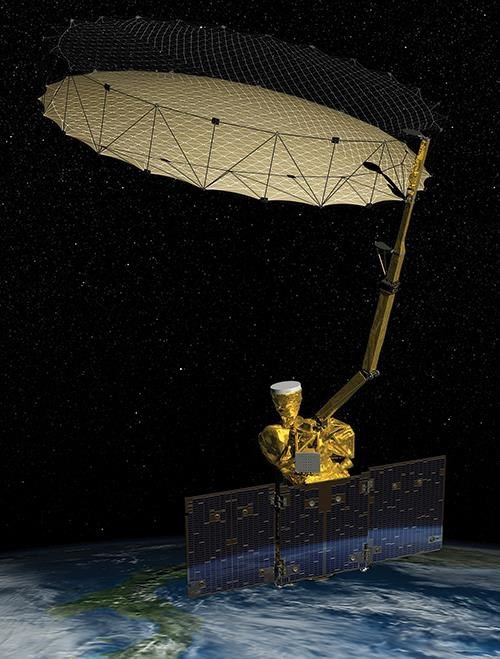

In 2015, NASA’s Jet Propulsion Laboratory (JPL, Pasadena, CA, US) launched the Soil Moisture Active/Passive (SMAP) mission to measure ocean salinity and soil moisture from low-Earth orbit (LEO). SMAP’s single spacecraft used new instrumentation, comprising an L-band radar and an L-band radiometer with a shared feedhorn and a 6m mesh reflector dish.

The reflector is cantilevered out from the spacecraft by a 3.35m long articulated boom. The feedhorn, reflector and boom assembly (RBA) rotate at 14.6 rpm, so that a 1,000-km-wide swath on Earth’s surface can be measured continuously, enabling complete scanning of the planet’s surface every three days.

“The requirements for the rotating RBA on SMAP were unprecedented in scope,” says Daniel Ochoa, the product development manager at Northrop Grumman Astro Aerospace (Carpinteria, CA, US) and part of the engineering team responsible for the final design. “Not only did the deployable RBA have to be exceptionally light and stable to minimize deflection during high-speed rotation, it also had to have extremely accurate and predictable mass properties when spinning.”

Established in 1958 as Astro Aerospace, Ochoa’s group is now a business unit of Northrop Grumman Aerospace Systems (Redondo Beach, CA, US). “Our deployable antennas and structures are orbiting the Earth, the Moon and Mars, and traveling beyond our Solar System on the Voyager spacecraft, still measuring the effects of solar winds and magnetic fields 35 years after launch,” he says. With a 100% success rate in mission deployments, the group understood the design challenge SMAP presented. “SMAP is the largest rotating reflector, as well as the largest mass-balanced reflector, ever built. We’ve built reflectors 12m in diameter, but they don’t spin.”

The dish was designed to be deployable, furled into a small space — 1.83m by 0.36m — for launch, and then, after entry into orbit, unfurled to form a precise reflective surface.

Precise, accurate focus in motion

To the SMAP’s L-band radiometer, very dry soil on Earth appears to be about 300oK. Very moist soil shows as roughly 100oK. These are not physical temperatures, but the temperature of naturally occurring L-band emissions from Earth’s surface. “By measuring the brightness temperature of a plot of soil, you can quickly estimate what the water content is down to about 4% accuracy, which is pretty incredible,” explains Kent Kellogg, JPL’s SMAP project manager. He notes that the L-band radar is much less accurate but contributes high resolution. “The real aperture resolution of the radio- meter, which is basically the spot size it reads on Earth, is 40 km,” says Kellogg. “But with the radar, we can generate what’s called a synthetic aperture by making a series of measurements as the satellite is orbiting overhead.” Kellogg says this creates a virtual antenna that’s much larger than the 6m reflector, improving the radar’s resolution to as fine as 1 km.

Thus, the accuracy of dish size and shape are key. Kellogg likens it to a parabolic mirror with a flashlight out in front at the focal point. All the light rays are collected by the mirror into a focused beam, instead of scattering if the light were pointing into open space. For the SMAP reflector antenna, the radar feed is similarly placed at the focal point of the parabola. The boom holds the reflector out in front of the light bulb, which, in this case, is the radar and radiometer feed, so that all of the radio frequency (RF) energy leaves collimated (in parallel), focused into a fairly tight beam.

Lightweight composite solution

For the SMAP reflector, Astro Aerospace chose its latest and lightest AstroMesh Lite product line. Optimized for 3-8m aperture reflectors, its surface is a knitted, gold-plated molybdenum wire mesh supported by hundreds of aramid-reinforced polyetherimide (PEI) tapes. “We approximate a perfect parabolic surface via a supporting lattice of triangular facets made from these composite webs,” Ochoa explains. The tapes use Twaron T2200 fiber (2420 dtex), supplied by TEIJIN ARAMID BV (Arnhem, The Netherlands), and Ultem 1010 PEI from SABIC (Pittsfield, MA, US).

In a proprietary process, the tape is pultruded by TenCate Advanced Composites (Morgan Hill, CA, US). The composite webs — some as long as 6m — were welded together to form the support lattice, which was then attached to a collapsible circular perimeter truss structure made from carbon fiber-reinforced epoxy tubes and bonded joints (see Fig. 1 and Learn More, below).

“When the truss structure is fully deployed,” says Ochoa, “it pulls the mesh and composite webs into tension, like a drum or high-performance tennis racket.” Astro Aerospace structural engineering manager Michael Beers says the thermoplastic composite offers “a good balance between flexibility — allowing us to compact the whole structure, yet deliver the required stability — and stiffness, once deployed.” The composite construction was a key to meeting mass requirements: The reflector weighs in at 25 kg, and the system, with boom, totals a mere 58 kg.

Modeling to meet mass balance requirements

“We provided very accurate mass data, moments-of-inertia and center-of-gravity specifications to JPL so they’d know the precise characteristics of this reflector,” Ochoa recalls. “We modeled and weighed each one of our 15,000 individual parts as we were building them, then again in different phases of construction, through to final assembly.” He notes that the mass measurements they needed were so unprecedented, “we had to invent new methods to acquire them.” For example, machines used to balance aeroengine blades were brought in for some tests. “They were so sensitive that breathing near them skewed the results,” Ochoa quips. He explains this level of accuracy was imperative, “because the large reflector, designed to function in the microgravity of space, could not be cost-effectively spun-up in the 1G of Earth, so we had to be absolutely certain before launch.”

The RBA mass had to be kept within a 99g window, and the center of mass within 12.7 mm. The boom had to extend the reflector 3.35m off the deck of the spacecraft at a 40° angle and be stiff enough to maintain expected alignment without distorting the reflector surface when spun up to 14.6 rpm. “The shape of the reflective surface defined by the composite webs must be exact to provide the required radar performance,” explains Ochoa. “The CFRP boom also would deflect with the load of the dish, so then the reflector moves as a result,” he adds.

To compensate for the deflection, says Beers, “we had to predict deflections for spinning, using computer modeling, and also account for the deformations in the structure and mesh due to spinning.”

“We built the reflector and boom knowing exactly how the spinning shape would differ from the original shape,” Ochoa explains. “We had to make sure that the reflector shape changed in a controlled manner, so we attached specific masses, or counter- balances, on the reflector where necessary.”

There also was a strict tolerance — 350 millidegrees — on where the RBA would point, i.e., where it would reflect the RF beam. Ochoa translates, “One millidegree rotation of our assembly trans- lates to an offset of about the thickness of a hair at the reflector tip.”

Details of deployable structure design

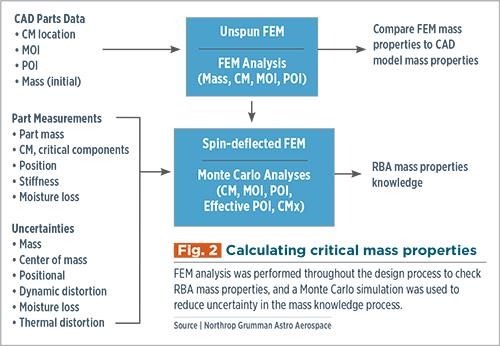

The minimum resonant frequency for the stowed RBA was 50 Hz in the axial direction and 35 Hz in the lateral. It also had to resist random vibration during launch. Femap with NX Nastran by Siemens PLM Software Inc. (Plano, TX, US) was used to develop multiple finite element models (FEMs) and perform various stowed RBA vibrational analyses.

Femap also was used to calculate the RBA’s mass properties and then re-run the mass properties model throughout the design process to ensure that the effective product of inertia (POI) and center of mass (CM) remained within required limits.

Large uncertainties at the beginning of the RBA design process prompted a sensitivity study. A Monte Carlo simulation based on a Femap-created FEM was used to examine the effects of seven sources of uncertainty (see Fig. 2, below) on the RBA mass proper- ties. The simulation ran 10,000 mass cases, using a uniform distribution of random inputs for each uncertainty. Results showed the required accuracy for part size, CM and positional measurements, and identified parts critical for overall system POI and CM properties. For these, the center of mass was verified with a measurement. The mass from the CAD model was used for all others.

Success in space

When the satellite was finally launched, positioned in LEO and spun up to operational speed, SMAP’s RBA deployed as planned. JPL mission control reported that system alignment was and still is about as close to perfect as it could get. Northrop Grumman Astro Aerospace’s lengthy design process and hard work clearly paid off. In late 2016, the company also was awarded the contract to supply the 12m diameter AstroMesh reflector for JPL’s NISAR (NASA Isro Synthetic Aperature Radar) mission.

What’s next? “The market for large mesh deployable reflectors is very strong,” says Ochoa. “There are requests for products from all across the space spectrum, such as Starshade, a NASA/ JPL mission to identify Earth-like planets in other star systems. “Composites already feature heavily in our preliminary designs for Starshade,” says Ochoa, “as well as for the large aperture deployable antenna for the NISAR spacecraft, which is designed to observe and measure some of the planet’s most complex processes.” He is confident that composites and Astro Aerospace are up to the challenge.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More