Proving time, cost savings in Hardenberg

The first SUREbridge installation was completed in October 2021 on a vehicle bridge in Hardenberg, Netherlands. A FiberCore Europe composite deck was bonded onto the existing concrete deck, doubling its load-carrying capacity in just six weeks. Photo Credit, all images: InfraCore, FiberCore Europe

Most of the roughly 1 million concrete bridges and viaducts in Europe are more than 50 years old, exceeding their design life. Many suffer from damage due to ingress of deicing salts which corrode the steel rebar and spall the concrete. Many bridges were also not designed for the increased traffic and vehicle loads they must now sustain.

It is estimated that at least 10% of all concrete structures in Europe must be refurbished or replaced before 2030 to prevent unsafe situations such as the Morandi Bridge collapse in Genoa, Italy. In that case, even though cracks and corrosion were seen in the steel-reinforced concrete cable stays beginning only 20 years after it was built, some crucial refurbishment was put off. “A bridge is like a car,” says Luigi Gambarotta, professor of structural mechanics at the University of Genoa, in a 2019 article by Guglielmo Mattioli published in The Guardian. “You can’t overload it, and to keep it working you need to change the broken parts.”

According to the 2021 Infrastructure Report Card – Bridges, 42% of the 617,000 bridges in the U.S. are more than 50 years old and 46,154 (7.5%) are considered structurally deficient. The pace of addressing the 231,000 bridges that need repair has slowed to 0.1% annually, which the 2021 bridge report warns is not sustainable. At the current rate, repair of these bridges will take more than 50 years; but the rate of deterioration is exceeding the rate of repair or replacement. The U.S. Federal Highway Administration (FHA) estimates the bridge repair backlog at $125 billion and that spending on bridge rehabilitation should be increased by 58%. Time is running out and funding is short.

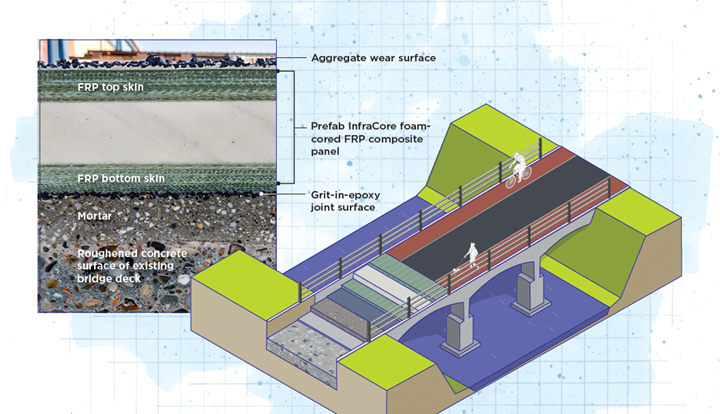

Composites provide a solution, as noted in the U.S. bridge report card’s Innovation section, providing increased strength, durability and longer life. Transport ministries across Europe have noted the same. In 2014, SUREbridge (Sustainable Refurbishment of Existing Bridges) was one of nine projects funded by the European Commission, the U.S. Dept. of Transportation and other partners via the Infravation (Infrastructure Innovation) program. The SUREbridge project (Oct 2015 – Mar 2018) was managed by Rijkswaterstaat (the Dutch ministry for infrastructure) and included Chalmers University of Technology (Göteborg, Sweden), FiberCore Europe (Rotterdam, Netherlands) and AICE Consulting in conjunction with the University of Pisa, both based in Pisa, Italy. It developed and demonstrated a solution that uses an InfraCore (Rotterdam, Netherlands) fiber-reinforced polymer (FRP) composite deck adhesively bonded to the top of an existing concrete bridge deck. If needed, prestressed carbon fiber composites can be added beneath the existing deck for additional support, using decades-old, well-proven bonded CFRP strengthening techniques.

SUREbridge test results showed that the original carrying capacity of a bridge could be more than doubled, enabling widening of the deck to accommodate a pedestrian or bicycle path. The method was also validated in a 2017 study on a 60-meter-long vehicle traffic bridge that crosses the Elsa River in San Miniato, Italy. Now, the first pilot project has been completed: a vehicle bridge in the town of Hardenberg, Netherlands. “The experience from this first case history is that we can upgrade the bridge in half the time and for half the cost compared to demolishing the old bridge and building a new one,” says Martijn Veltkamp, design lead at FiberCore Europe (see “Plant Tour: FiberCore Europe, Rotterdam, Netherlands”).

Sustainable design showcased in Hardenberg

Built in the 1960s, the bridge over the Radewijkerbeek in Hardenberg is mainly used by local residents and increasing traffic, including heavy agricultural vehicles, for which it was not designed. Due to the poor quality of its concrete structure, damaged by deicing salts, the only options for the bridge were demolition and new construction or SUREbridge.

Aging, damaged infrastructure

Built in the 1960s, this bridge in Hardenberg, Netherlands, was not designed for the heavier loads and traffic that it must withstand today. Instead of demolishing the damaged concrete, it was strengthened with a prefabricated composite deck using the SUREbridge technology.

The municipality of Hardenberg chose and implemented the latter with a team comprising FiberCore Europe and the large infrastructure contractor Strukton Civiel (Utrecht), as well as regional contractor Van Heteren (Hengelo) and engineering firm Nepocon (Hengelo). This team supervised an extensive pre-construction study, followed by a process to optimize and specify the design. It then completed repairs and preparation for the FRP deck. A single composite panel measuring 4.8 x 19.6 meters was fabricated and bonded to the existing deck using pumped concrete mortar. With the old railings removed, the new FRP deck panel allowed the bridge to be widened by 50 centimeters on each side. Once the design was finalized, the SUREbridge refurbishment process was completed in six weeks.

Pre-construction study and preparation

A preliminary investigation and engineering design phase is required for any repair or replacement technique, says Veltkamp. “This can take several weeks and is conducted by the municipality or roads authority.” It includes researching the bridge’s original design, inspecting the structures and foundation of the bridge and conducting chloride penetration tests to determine how far deicing salts have penetrated the concrete structures. “We use this data to determine the SUREbridge parameters such as thickness of the FRP deck,” he adds. “The more we know about the bridge, the better we can design the SUREbridge retrofit with certainty versus just making it heavy, thick and overly conservative, which is expensive. We also want to make sure we avoid any hidden surprises, which will increase the cost and time required. There is also the possibility that the condition of the bridge is so degraded that the only solution is indeed to demolish and build a new one. All of this must be determined.”

The calculations to design the new SUREbridge deck are performed using CAD models and a software tool developed and tested during the Infravation project. The software inputs properties of the existing bridge as well as those of the new FRP composite deck to output the structural performance of the refurbished bridge. This can include combination with CFRP strengthening on the underside of the concrete deck. “But often this isn’t necessary as the FRP composite deck on top already brings sufficient additional strength,” says Veltkamp. He adds that the SUREbridge CAD models and calculation tool have been validated via one-to-one tests where size, conditions, materials and equipment corresponded to actual industry practice. “The results also showed that performance is not vulnerable to execution errors,” notes Veltkamp, “meaning SUREbridge designs are very robust.”

With the pre-construction investigation, optimized design, technical specifications and permitting complete, SUREbridge construction in Hardenberg could begin. The first phase involved removing existing asphalt, curbs and rails, if necessary, followed by completing minor repairs to the concrete deck and/or underlying concrete supports, where needed.

“The amount of repair depends on the condition of the bridge structure,” says Veltkamp. “Typically, there are discrete areas that need to be addressed before we can proceed with the FRP deck. When applied correctly, concrete is a good construction material. But these bridges use mostly in-situ poured concrete and if you build things outdoors, the quality is not always homogeneous. Rainy days, variations in the concrete mix or not enough vibration to avoid air pockets during the pour can all result in localized areas more vulnerable to damage. Also, if salt has penetrated and started to corrode the rebar, then there might be spalled concrete. Anything loose like that will have to be removed. Before we can place a new deck, we make sure the underlying structure is good and ready to proceed.”

For the Hardenberg bridge, this process took two days. One last preparation step was to roughen the existing concrete deck by hammering its surface. “This will help ensure a good bond with the mortar that will be pumped between this surface and the new FRP deck,” says Veltkamp.

Building and positioning the FRP deck

As explained in CW’s 2017 tour of FiberCore Europe, its FRP bridge deck designs are driven by strength, not stiffness properties. The resulting decks can match the strength of steel at one-fifth the weight, are 20-50% less expensive and are also much easier to transport and install. Multiaxial glass fiber fabrics for the bottom skin are placed into the mold, followed by beams of polyurethane foam wrapped in glass fabric and another set of fabric plies for the top skin. This dry layup is vacuum bagged and infused with resin. For the Hardenberg bridge, FiberCore used polyester resin from Polynt (Scanzorosciate, Bergamo, Italy) and fabrics from Kush Synthetics (Ahmedabad, Gujarat, India), which has distribution in Enschede, Netherlands and Atlanta, Ga., U.S.

After resin infusion and room temperature cure is complete, the FRP panel is a single, integrated structure. The InfraCore Inside technology results in a uniquely delamination-resistant construction, based on the design of oblique layered materials like armadillo shells and snake scales. During full-size bridge deck testing, purposely created holes to simulate impact damage did not propagate after 30 million cycles of up to 13.5 megatons of tire-sized loading which was used to represent vehicle traffic.

Quick installation

A crane lowers the prefabricated FRP bridge deck panel onto the bridge’s existing concrete deck. Installation, including preparing the concrete, injecting mortar to bond the FRP deck and finishing roadway and handrails, was completed in six weeks.

The completed FRP deck for Hardenberg was transported to the site, but the SUREbridge technique required one more step before installation. “If you simply put the FRP deck on the concrete deck, you would have no interspace to allow for creating the bond,” explains Veltkamp. “You need a few centimeters of gap where the mortar — which is the glue between the concrete deck and the FRP panel — can be pumped into. To create space, we place the deck on a series of bolts, which can be screwed and unscrewed, so that it is relatively easy to align the FRP deck as needed. For example, you may want the deck to sit level horizontally or be inclined.”

Two-part bonded joint

Once the FRP deck is installed and positioned with the bolts, concrete mortar can be pumped into the space between the new and old decks. Here, too, there are factors to consider, says Veltkamp. “The bridge is long and wide, so you don’t inject concrete at one end, wait an hour and then it is at the other end because the mortar is really thick. Rather than making the concrete flow over the entire area, we start injecting it at one end and then when we see it has progressed about one-and-a-half meters, we begin with a new injection point. Thus, the distance to complete one patch of surface is only around two meters. We use multiple injection points along the span. It is somewhat like a resin infusion setup in composites, where new inlets for resin feed lines are spaced along the length.”

“As the pump is injecting mortar into the interspace,” continues Veltkamp, “the air on the other side being pushed forward also needs to get out. Thus, there are inlets for the mortar and outlets for the air. Again, it is very similar to the resin infusion strategy you would need in order to avoid trapped air in a composite part.”

Another point in the design of the SUREbridge technique is that both surfaces that contact the mortar are roughened. Not only is the existing concrete deck surface roughened but the underside of the FRP deck has an epoxy layer with aggregate grit in it. “Normally, the surface of an FRP panel is quite smooth,” says Veltkamp, “and this isn’t rough enough to make the FRP stick to the concrete mortar glue. You need surface preparation to enable both chemical bonding and mechanical bonding, creating a shear-resistant joint.”

Any epoxy approved for this purpose by the local authorities can be used for the underside of the FRP deck, says Veltkamp. “The epoxy we use is produced by a local supplier, but we have multiple companies around the world that have licensed the InfraCore and SUREbridge technology, and they use epoxies that are sourced in their regions.”

Increased sustainability, future potential

“First and probably foremost, is that by using SUREbridge you avoid demolishing the bridge and actually reuse it,” says Veltkamp. “This extended use represents an estimated 50% reduction in CO2 emissions compared to building a new bridge. And that means more than just avoiding waste, because it greatly reduces how long the bridge is out of use.” Refurbishing with SUREbridge takes just four to six weeks. “The faster the refurbishment can be done, the less detouring is required,” he points out, which further reduces CO2 emissions and reduces the cost of the associated travel time, or what is referred to in the U.S. as VTTS: Value of Travel Time Savings.

Why four to six weeks, if — depending on the size and state of the bridge — preparation/repair, panel installation and mortar injection can be completed in four to five days? “Because the mortar is concrete, which typically takes 28 days to harden and reach full strength,” says Veltkamp. “For a normal concrete bridge rebuild, there would be one concrete pour for the columns underneath and another pour for the deck on top. That totals two sets of 28 days or eight weeks. For us, most of the six weeks is again for the concrete mortar to harden and reach full strength. However, after a week, the mortar will already have achieved 50% strength so that finishes such as the entry and exit slopes, and perhaps even the rails can be completed. So, if the preparation required is moderate and you start the finishings as the concrete is reaching full strength, then you can compress the cycle to at least 50% of the time to build a new bridge.”

Compared to overlaying existing bridges with new concrete, SUREbridge offers a corrosion-resistant FRP overlay that is much lighter in weight so that no additional reinforcement is required to support the deck. The FRP also prevents future penetration of deicing salts into the underlying deck. Moreover, SUREbridge decks are prefabricated, thus high quality is easier to ensure. Avoiding demolition and the fast installation means considerably fewer transport movements and emissions.

Thanks to the success of the Hardenberg project, FiberCore Europe is seeing increased interest. “We are seeing a wave now of preparing feasibility studies for bridges,” says Veltkamp. “Engineers are calling and asking us to educate them about this approach and how to perform the calculations. We are beginning at the level of consulting and seeing these slowly proceed toward more SUREbridge refurbishment projects.”

U.S. licensee Orenco Composites (Roseburg, Ore., U.S.) also sees increasing interest. “There are many aging concrete bridges that have derated load capacities, sometimes down to one lane,” says Andy Bridge, director of business development at Orenco. “SUREbridge provides a low-cost, rapidly deployed option for restoring certain bridge types or even increasing their load capacity. We are having discussions with stakeholders in the U.S. to identify candidate demonstration projects. The FHWA [Federal Highway Administration] is encouraging market-ready innovations for accelerated deployment under the Every Day Counts Program [EDC]. As we see state DOTs trying to maximize their return on investment to replace or repair bridges, Orenco Composites is excited to offer SUREbridge as a solution.”

In the Netherlands, FiberCore Europe’s partner in Hardenberg, Strukton Civiel, sees SUREbridge as a key offering in its palette of intelligent solutions. “They see a strong business potential in being involved in refurbishment projects early and are using sensors and data analysis to identify when problems start to arise in bridges,” notes Veltkamp. SUREbridge is indicative of Strukton Civiel’s “Infrastructure of the Future” strategy, which, he says, “is about using the latest technology to upgrade what we have, which is a more sustainable, and thus, smarter thing to do.”

Related Content

Composites enable massive wastewater infrastructure project

To build complex drop shafts for New Zealand’s Central Interceptor project, RPC Technologies pushed the limits with glass and carbon fiber, vertical filament winding and UV-cure resins.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreRead Next

Fibrolux supports Polish bridge with custom pultruded deck beams

More than 16 kilometers of fiberglass-pultruded profiles double Marshal Jozef Pilsudski Bridge capacity and upgrade its durability.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More