An MCAM customer wanted to replace metal injection molded (MIM) magnesium with a composite on a performance mountain bike’s suspension elements with the goals of reducing mass and avoiding processing concerns with the reactive alkaline earth metal. Given the complexity of the part and the production volumes involved, only injection molding could meet the customer’s price point. MCAM formulated a 30% FWF short carbon fiber-reinforced polyphenylene sulfide (PPS) composite (KyronMAX S-8230) that met all mechanical requirements — including challenging fatigue targets — and successfully replaced magnesium in this application. Photo Credit, all images: Mitsubishi Chemical Advanced Materials Inc.

A family of short carbon fiber-reinforced thermoplastic (CFRTP) compounds specifically formulated for injection molding is being used to extend the capabilities of thermoplastic composites in a variety of part sizes and complexities. Interestingly, these materials have been shown to outperform long fiber thermoplastic (LFT) composites (in fiberglass or carbon fiber) as well as metals in a growing range of applications — from sporting goods and car parts to medical devices and aerospace components.

Molder turned compounder

The materials are formulated and sold by Mitsubishi Chemical Advanced Materials Inc. (MCAM, Tokyo, Japan). MCAM combines several previously separate businesses acquired by the parent company over the last decade. These include the former Quadrant AG (Lenzburg, Switzerland), a producer of glass mat thermoplastic (GMT) and organosheet composites as well as thermoplastic engineered shapes, and what had been Piper Plastics Inc. (Chandler, Ariz., U.S.), which started life as an injection molder and producer of precision machined parts, and later expanded into custom CFRTP compounding — first for its own use and later for other molders.

Circa 2012, Piper was a midsize custom injection molder serving a customer base in aerospace and sporting goods/recreational equipment. Company leadership wanted to grow its parts-making business but had two challenges. First, it was having trouble sourcing the kinds of compounds the team felt would enable the company to compete in higher performance market segments. Second, the company wanted to enter the automotive market, but didn’t have enough available molding capacity to compete on major programs.

This idler wheel that is part of a performance compound archery bow was originally produced in machined aluminum. The customer wanted to convert to composites, so initially tried 50% FWF long glass PA6/6. However, that material had challenges filling the complex geometry, which led to premature failure of the part. MCAM formulated a 20% FWF short carbon fiber-reinforced PA6/6 composite (KyronMAX S 2220) for the application. Not only was the new composite able to be molded in the same tool as the LFT grade without modification, but failures were eliminated and weight was reduced 21% versus the LFT material and 50% versus the original aluminum.

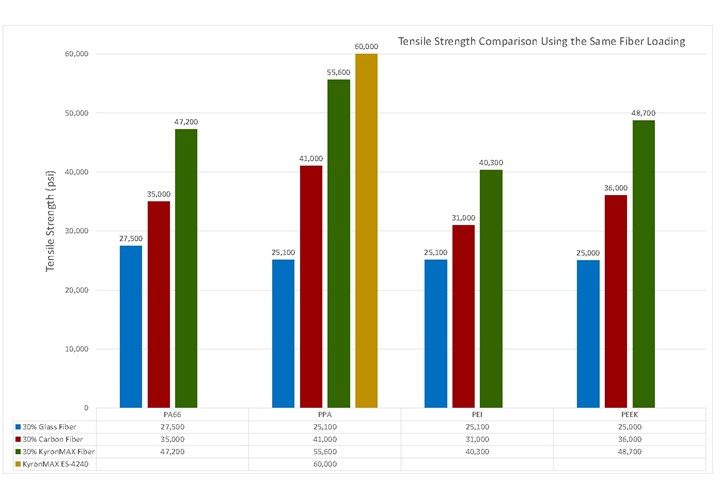

The first problem was solved by applying a focused R&D effort on various base resins and fiber sizing technologies, which led to the development of a family of high-performance, injection moldable CFRTP compounds called KyronMAX. These materials feature matrices such as polyamide 6/6 (PA6/6), polyphthalamide (PPA), polyetherimide (PEI), polyphenylene sulfide (PPS), polyetheretherketone (PEEK) and polyaryletherketone (PAEK) reinforced with short chopped carbon fiber. The compounds — most of which offer high thermal performance, broad chemical resistance, good mechanicals and low flame/smoke/toxicity (FST) values — were formulated not only to replace short glass fiber-reinforced and mineral-filled injection molding grades, but also LFT compounds (with average starting fiber length of 13 millimeters) and even metals.

“On a datasheet, LFT compounds look stronger, but often they’re unable to fill the kinds of part geometry we can fill with short carbon fiber technology,” explains Alex Wojtysiak, MCAM key accounts manager – composites. “Because our flow is so much higher, we’re better able to fill intricate geometry, so our compounds produce parts that are dramatically stronger.”

“It’s not so much that we set out to create a broad range of CFRTP compounds but that each one was developed to meet the specific needs of a particular customer,” adds Clint Newell, MCAM global composites technology manager. “As our formulation capabilities grew, we entered new markets, met with new customers, asked what they needed and set about creating a perfect compound to meet those needs.”

Unsurprisingly, because these compounds were initially formulated by a molder for a molder, they were designed to provide properties that made them easy to process and to consistently yield higher quality, better performing parts. “We formulated our KyronMAX product line to provide higher flow and fiber interaction, lower internal stresses, less anisotropy, stronger weld lines, fewer sink marks, less tendency for warpage and greater dimensional accuracy — regardless of whether wall sections were thick or thin,” notes Dave Wilkinson, MCAM R&D director. “In addition to our formulation work and unique sizing technology, we also made our own press modifications to run these materials more efficiently.”

Why the unusual product name? “In ancient Greek myths, Kyron (also spelled Chiron) was part centaur and part human,” explains Randy White, MCAM chief innovation officer. “Kyron used his unique personal skills to rise above his beastly nature. We likened that to our compounds, which are half carbon fiber and half resin, so as strong as a horse and as smart as a human for ease of processing.”

As formulation expertise grew, the company came to the attention of Mitsubishi Chemical Holdings Group (MCHC, Tokyo, Japan), which acquired Piper in 2016. MCHC immediately made a substantial multi-million dollar investment to increase the size of the compounding line in Arizona, automate operations and bring in its own carbon fiber sizing and chopping technologies to enable KyronMAX compounds to be produced faster and with greater consistency and efficiency. Subsequently, a second compounding line was set up in Michigan and a third in Japan. This expanded capacity meant that KyronMAX grades could compete for automotive business in North America and in Asia. Other markets have followed.

Expanded product offering, new market opportunities

Now, with greater production capacity and access to a broader array of polymer and carbon fiber materials, the MCAM team has been busy developing an array of new products — several of them specifically formulated for the automotive market. One of the most interesting is KyronMAX ES 4240, said to be the world’s first short carbon fiber injection molding compound to break the 414 MPa (60,000 psi) tensile strength barrier. That grade, which was introduced at the 2019 SPE Automotive Engineered Plastics Conference (AutoEPCON) in the Detroit suburbs, is a 40% fiber weight fraction (FWF) carbon fiber-reinforced PPA that also offers tensile modulus values of 41.2 GPa, flexural modulus values of 34.5 GPa and flexural strength values of 552 MPa. PPA is a specialized form of polyamide with better thermal and broader chemical resistance and far lower tendency toward hydrolysis than conventional PA6 and PA6/6.

Among the new injection moldable CFRTP compounds specifically developed for automotive use is KyronMAX ES 4240, a 40 FWF short carbon fiber-reinforced PPA said to be the first to break the 414-MPa (60,000 psi) tensile strength barrier.

Other automotive grades introduced at the 2019 SPE AutoEPCON include a high-temperature carbon fiber-reinforced PPA grade specifically developed for underhood applications. That grade is said to have a glass transition temperature (Tg) and continuous-use temperature (CUT) rivaling that of PEEK, but is easier to mold. Given the cost sensitivity of high-volume industries like automotive and small appliances, it comes as no surprise to learn that the team also is working on a polypropylene (PP)-based KyronMAX product.

As its product line has expanded, so too have the markets in which these materials are used. In addition to long-desired automotive business, the company now serves medical device (both durable and disposable), small appliance and consumer electronics (metal replacement cases/covers). Aviation/aerospace is still important, as is the sporting goods industry, which has grown to include applications on racing bikes, mountain bikes, golf clubs, firearms, compound bows and other archery parts. With several products offering coefficient of linear thermal expansion (CLTE) values similar to those of metal injection molded (MIM) aluminum and magnesium — albeit with better toughness, lighter weight and lower cost — the team finds itself replacing metals in an increasing array of applications.

To demonstrate the performance capabilities of KyronMAX composites to aerospace customers, MCAM designed and produced a generic quarter-turn retaining latch for use in aircraft galleys. The parts are currently produced in aluminum owing to high load requirements. A 30% FWF short carbon fiber/PEI grade (KyronMAX S 6230) was selected both for its mechanical performance as well as its flame/smoke/toxicity (FST) listing. The composite parts meet the performance requirements of aluminum at half the weight and are currently being evaluated by several customers. They also permit painting to match aircraft interiors.

What’s next? With access to the broader Mitsubishi organization globally, the MCAM team can access technology representing a broader composites portfolio that spans thermoplastic as well as thermoset chemistries, with a range of reinforcement types and lengths. For example, another Mitsubishi group produces split and chopped tow carbon fiber-reinforced forged molding compound (FMC), an advanced form of sheet molding compound (SMC) that helps bridge the performance and processing gap between short glass or carbon fiber-reinforced SMC and continuous carbon fiber-reinforced prepreg. Still another group produces woven and nonwoven carbon fiber reinforced prepreg and rapid-cure prepreg compression molding (PCM) materials.

Within MCAM itself, another technology that’s nearing commercialization is a new family of textile (nonwoven, woven and unidirectional)-reinforced dry prepregs with thermoplastic matrices called KyronTEX. These products are currently being strategically sampled.

Finally, last summer MCAM acquired carbonNXT GmbH and sister company CFK Valley State Recycling GmbH and Co. KG (both Wischhafen, Germany), bringing a complete line of carbon fiber recycling technology into the group’s product offering. The MCAM team is said to be testing multiple formulas using recycled carbon fiber ahead of qualifying commercial products.

This article was originally published 9/22/2021, updated 7/14/2022

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)