SpaceX announces COPV’s role in September rocket explosion

Buckles (voids) between carbon composite overwrap and aluminum liner in cryotank led to ignition of super chilled oxygen — will be fixed long-term via COPV design change.

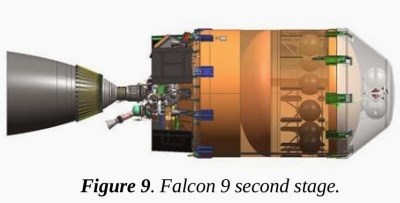

Helium-containing COPVs are shown as small black orbs within

the larger LOX tank (green clips are around of it at right).

SOURCE: Reddit.

SpaceX has announced conclusions from the accident investigation team as to the cause of the Sept. 1, 2016 explosion during fueling of a Falcon 9 launch vehicle in preparation for a launch at Cape Canaveral, Florida. The team — comprising the Federal Aviation Administration (FAA), the U.S. Air Force (USAF), the National Aeronautics and Space Administration (NASA), the National Transportation Safety Board (NTSB) and several industry experts — collaborated with SpaceX to review more than 3,000 channels of video and telemetry data from the 93-millisecond timeline between first anomalous data to loss of the second stage rocket. In addition, umbilical data, ground-based video and physical debris were analyzed, with SpaceX conducting a wide range of tests at its Hawthorne, CA, and McGregor, TX, facilities.

The team has concluded that one of the three composite overwrapped pressure vessels (COPVs) inside the second stage liquid oxygen (LOX) tank failed. These COPVs use the industry standard of carbon fiber composite wrapped over an aluminum liner, and are designed to hold super-cold helium (He) under high pressure. Attached inside the Falcon 9’s larger tank of cold LOX propellant, the smaller He COPVs are used to maintain pressure in that tank.

The failure is believed to have resulted from accumulation of oxygen between the COPV's aluminum liner and composite overwrap in a void or buckle. Recovered COPVs showed such buckles. Although testing showed that buckles on their own will not burst a COPV, investigators concluded that super chilled LOX can pool in these buckles and become trapped beneath the overwrap when the vessel is pressurized. The entrapped oxygen can either break overwrap fibers or cause friction between fibers as it swells, igniting the oxygen and causing the COPV to fail.

According to a QUARTZ article by Tim Fernholz, SpaceX began a new pre-flight fueling process in 2016 that allowed it to use even colder, and denser, LOX in its rockets. This increased the amount of propellant the tank could store and would allow the rocket to fly further, including returning to earth after a mission.

COPVs have a long history in space vehicles, but have also periodically faced issues. According to an Oct. 6, 2016 article in Space Safety magazine, the author cautions:

“It is essential to consider the pressure vessel as a system. The load is shared between the liner and the overwrap and changes in pressure can affect this load sharing. The temperature of the system is very critical … An increase in system temperature causes additional shifts in this load sharing. Mismanagement of this relationship, particularly during manufacture, can increase the potential for the liner to buckle during service, which is another form of catastrophic system failure.”

NASA 2.4m diameter all-composite cryotank built by Boeing with tooling from Janicki Industries was tested at NASA Marshall Space Flight Center (Huntsville, AL, US) in 2013. SOURCE: NASA.

Following the Columbia accident, the Space Shuttle Program reevaluated its COPV certification, re-certification and flight procedures. The Space Safety article notes,

“… improved flight procedures affecting the manner in which the vessels were loaded on the pad and the margins for re-pressurant quantities were reevaluated. A reduction in risk by a factor of six was realized without compromising the Shuttle payload capabilities.”

All articles dissecting the Sept. 1 Falcon 9 accident agree that COPV design, manufacture, testing and use involves a complex set of variables. The QUARTZ article noted how SpaceX appeared to have mastered these complexities and other sources note that the company builds its own COPVs.

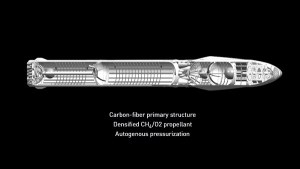

In fact, Elon Musk unveiled the largest composite cryotank ever built at the 2016 International Astronomical Congress (IAC, Guadalajara, Mexico). Developed for the 122m tall Interplanetary Transport System (ITS, with 49.5m long spaceship on top) for travel to and from Mars, the tank has a reported 12m diameter. It was successfully pressure-tested at two-thirds burst pressure in November 2016 and is next slated for full cryogenic testing. In an ask-me-anything (AMA) session on Reddit, the SpaceX founder said the development tank was the same diameter but slightly shorter than the flight tank will be and is made with “the latest and greatest carbon fiber prepreg. In theory, it should hold cryogenic propellant without leaking and without a sealing liner.”

Technologies for composite tanks without an aluminum liner were discussed by Sara Black in a 2005 CW article, and CW has written extensively about NASA’s composite cryotank.

|

|

SpaceX has built the world’s largest composite cryogenic tank.

SOURCE: Reddit, SpaceX, Elon Musk and FastCompany (bottom left photo).

Corrections and design changes

For the smaller Falcon 9 COPVs, SpaceX will take immediate corrective actions including changing the COPV configuration to allow warmer temperature helium to be loaded and returning these loading operations to the prior configuration proven in over 700 successful COPV loads.

Longer-term, however, SpaceX said it will implement COPV design changes to prevent buckles altogether while enabling faster loading operations. The company is targeting return to flight from Vandenberg's Space Launch Complex 4E (SLC-4E) with the Iridium NEXT launch on Jan. 8, 2017.

Similar to all pioneers who push the boundaries of technology and manmade achievement, this is not the first challenge SpaceX has faced, nor will it be the last. What will be interesting is to see how the company’s solutions to these challenges — COPVs at very low temps and fast loading times and very large all-composite tanks — will open the door for new composite materials and processes and new achievements in space exploration technology.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More