SPE’S ACCE 2015 Preview

Automotive composites remain a hot topic in the Motor City.

Composites remain a hot topic in the automotive industry as OEMs scramble to meet tough new fuel efficiency and/or tailpipe emissions standards that will come into full force in many parts of the globe in 2025. Any technology that can reduce mass and systems costs, improve durability and crash performance, eliminate secondary operations and enhance styling flexibility stands a good chance of beating out benchmark steel and more costly aluminum. Therefore, it’s not surprising that attendance continues to grow at the Automotive Composites Conference & Exhibition (ACCE) organized by the Automotive and Composites Divisions of the Society of Plastics Engineers (SPE, Bethel, CT, US). Now in its 15th year, the event returns Sept. 9-11 at the Diamond Center at the Suburban Collection Showplace (Novi, MI, US) in the Detroit suburbs.

Last year’s exhibition spilled out of the main Diamond Ballroom into Hall C, where lunch was served and the student poster and parts competitions were held, so this year, event organizers have moved all exhibits, meals and coffee breaks to that much larger space. So far, that seems to be a good decision: SPE reports that previous records for sponsorship dollars and the number and size of exhibits already have been broken — many exhibits will be larger this year owing to the additional room. To keep walking time between exhibits/food and session rooms short, all sessions will run either in the Diamond Ballroom (where keynotes and panel discussions also will be held) or the adjacent Emerald/Amethyst room.

Tech program: Slightly more compact but equally strong

One of the perennial strengths of the SPE ACCE is that it covers a broad array of materials and process technologies — from injection molded short-glass thermoplastics to autoclave-cured thermosetting carbon fiber-reinforced plastics (CFRP) and nearly everything in between. Although the 2015 technical papers list, at CW press time, was a little shorter than those of the past few years (77 regular papers, compared to 81 in 2014 and 90 in 2013), this year’s lineup continues SPE’s tradition of breadth as well as depth of topic.

Although sessions on polymers per se are smaller than in recent years, there is a large Enabling Technologies session on processing and equipment developments, with a strong showing in resin transfer molding (RTM) technologies, including high-pressure RTM, thermoplastic and surface RTM, and even cast-polyamide RTM. A standalone Bonding, Joining & Finishing session (last held in 2008) returns this year with talks on selecting surface films to improve adhesion between fabric and substrates, using flame and plasma surface treatments to improve bonding, and new work on reversible bonded joints, using nano-ferromagnetic particles.

An entirely new session this year, featuring the hot topics of additive manufacturing & 3D printing, is expected to be well-attended. The ever-popular Opportunities and Challenges with Carbon Composites session will feature a paper on preforming, 3D woven composites, lightweighting structural components, as well as a talk on composite powertrain components on the US Department of Energy project, the Multi Material Lightweight Vehicle (MMLV), developed by Ford Motor Co. (Dearborn, MI, US) and Magna International (Aurora, ON, Canada).

Also of special interest are two new papers on systems for inline production of CFRP prepreg — one developed by Mitsubishi Rayon Co. Ltd. (Tokyo, Japan) and another by the Fraunhofer Institute for Chemical Technology (ICT)(Pfinztal, Germany) — which hold the promise of doing for carbon fiber prepreg what inline compounded (ILC) direct long fiber thermoplastics (D-LFTs) did for compression-molded PP and polyamide (PA, also called nylon) in the late 1990s through mid-2000s.

The Nanocomposites session also is larger than usual this year, with a strong focus on newer nanocellulose and nanosilica particles. Always prominent at the SPE ACCE is the Virtual Prototyping & Testing session, which encompasses computer-aided simulation as well as physical part testing. This year’s session doesn’t disappoint, with several new offerings on draping simulation for fabric-reinforced composites, as well as simulations for impact, fatigue, durability, progressive failure, post-failure behavior, fiber orientation and anisotropic damping.

Another session with a good paper turnout for 2015 is Sustainable Composites, which includes biopolymers, recycled polymers and natural fiber composites. There are three smaller sessions on Advances in Thermoplastic Composites, Advances in Thermoset Composites and Advances in Reinforcements. These sessions will cover a wide variety of topics: development of a medium-duty truck bulkhead; hybrid long-fiber thermoplastics; new grades of lightweight reinforced thermoplastic (LWRT) composites for stone impacts; the effects of processing techniques on thermoplastic composites; the latest generation of fast-cycling polyurethane resins; lifecycle analysis of engineering thermosets vs. aluminum in an underhood application; lightweighting composites through selective fiber placement; and tools for chemical characterization of the process to convert lignin to carbon fiber.

ACCE’s popular Tutorials tracks are back with a two-hour presentation on “Adhesive Bonding of CFRP Composites: Practices and Principles” by Louis Dorworth of Abaris Training Resources Inc. (Reno, NV, US) and a 90-minute talk on “Bioplastics & Biocomposites for Automotive” by Karen Stoeffler of National Research Council Canada (NRCC, Ottawa, ON, Canada).

Lively panel discussions and diverse keynotes

Well known for its lively panel discussions, SPE ACCE this year has scheduled a 90-minute panel organized by Prof. Jan-Anders Månson, the head of the Laboratory of Polymer and Composite Materials (LTC) at the Institute of Materials, Ecole Polytechnique Fédérale de Lausanne (EPFL, Lausanne, Switzerland). Panelists, unconfirmed at CW press time, will focus on the topic, “Carbon Steel to Carbon Composites – Can the Existing Automotive Infrastructure be Leveraged to meet Lightweighting Targets?”

Another perennial ACCE distinction is its diverse keynote addresses, and this year won’t disappoint. Speakers confirmed by early July include Day 1 keynotes from Anthony Schiavo, research associate, Lux Research Inc. (Boston, MA, US) on the topic of “Carbon Fiber 2.0: Roadmap for Growth to 2020 and Beyond,” as well as a multi-speaker group that will address the timely topic of the “Institute for Advanced Composites Manufacturing Innovation (IACMI): A Disruptive Moment in Automotive History.” Presenters here will include Dr. Craig Blue, CEO, IACMI; IACMI directors Dr. Larry Drzal (Vehicles Technology) from Michigan State University; Dr. Byron Pipes (Modeling and Simulation Technology) from Purdue University; Dr. Brian Rice (Compressed Gas Storage Technology) from the University of Dayton Research Institute; and Cliff Eberle (Materials and Process Technology) from Oak Ridge National Laboratory. On Day 2 Deborah Mielewski, senior technical leader for Ford’s Sustainable Materials and Plastics Research, will give a talk titled “Owning the Future: Sustainable Materials Research, Development & Implementation at Ford.” After lunch on the same day, Stefan Stanglmaier, technology development CFK material and process safeguarding, BMW Group (Landshut, Germany), will address the topic of “Mass Production of CFRP in Automotive Applications – Potential and Challenges in Implementing Local Reinforcements.”

And on Day 3, Antony Dodworth, managing director, Brite Lite Structures (San Francisco, CA, US), will discuss “A Platform for Novel Lightweight Automotive Composite Structural Design.”

Social outings, awards & trophies

Popular aspects of the SPE ACCE include pre-event social outings in and around the Detroit region. One such event is the SPE Automotive Division’s annual day-long golf outing at beautiful Fieldstone Golf Club (Auburn Hills, MI, US). Another is a free tour of the new international headquarters of Continental Structural Plastics (CSP) in Auburn Hills, MI, US. SPE will provide transportation to and from the conference center for those who sign up ahead of time for the tour. Both the golf outing and the tour take place the day before the conference (on Tuesday, Sept. 8), and participants are invited to attend a reception that evening at the conference facility’s Fireside Room.

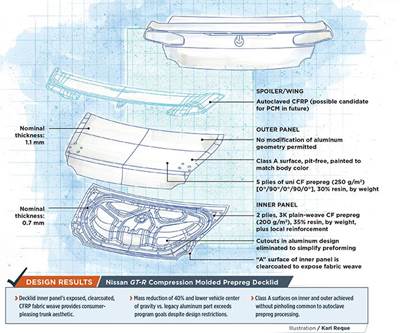

The ACCE also presents Best Paper and student scholarship awards at the event, and conducts a student poster competition and a Best Part competition (both judged at the event site). Last year’s Best Part – Body Exterior trophy went to Mitsubishi Chemical Carbon Fiber & Composites Inc. (Tokyo, Japan), which nominated the CFRP (carbon fiber-reinforced plastic) decklid made by its prepreg compression molding process, which was featured on the Nissan GT-R supercar by Nissan Motor Co. Ltd. (see “Prepreg compression molding makes commerical debut” under "Editor's Picks," at top right). The ACCE’s People’s Choice award (chosen by conference attendees) went to Momentive Specialty Chemicals Inc. (now Hexion Inc., Columbus, OH, US) for its nomination of lightweight carbon fiber door structure with Class A appearance on the Porsche 911 GT Cup supercar, produced by Porsche AG (Stuttgart, Germany).

A free SPE Events app can be downloaded from Android or iPhone/iPad app stores to view schedules, author bios and mini-abstracts of presentations, keynotes, panels and other event details.

Related Content

Scott Bader, Oxeco partner for high-performance bonding solution

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MorePittsburgh engineers receive $259K DARPA award for mussel-inspired underwater adhesion

The proposed META GLUE takes inspiration from hydrogels, liquid crystal elastomers and mussels’ natural bioadhesives to develop highly architected synthetic systems.

Read MoreRead Next

Prepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)