Thermoplastic composites: Occupant protection in transportation

European consortium develops, validates unique hybrid process for a glass/PA6 engine-compartment bulkhead to replace stamped steel on commercial trucks.

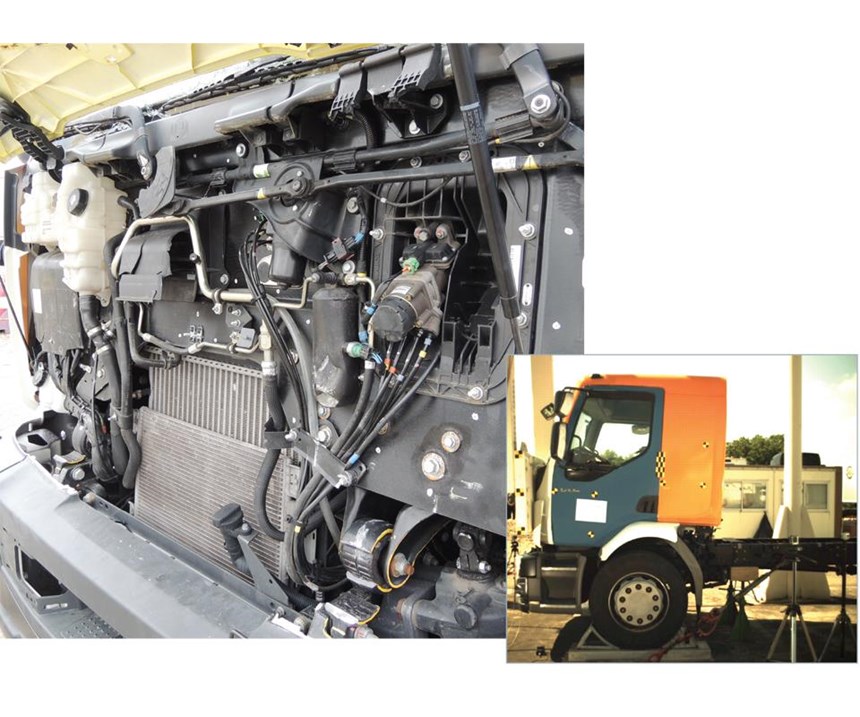

A European transportation-composites consortium, led by OEM Renault Trucks (Saint-Priest, France) and materials supplier Solvay (Brussels, Belgium), designed, produced and validated a thermoplastic composite engine-compartment bulkhead to replace a multi-piece stamped-steel assembly on a mid-size commercial truck. The project was noteworthy because bulkheads, which separate the engine compartment, with its heat and aggressive chemicals, from the passenger compartment, provide occupant protection. Further, the structural assembly is mounted to the body-in-white (BIW) and plays a safety role during crashes as well, making its performance both critical and challenging, given the vehicle’s size and weight. The bulkhead also plays roles in vehicle durability and in damping noise/vibration/harshness (NVH). The four-year program ended in 2015 and involved significant use of virtual prototyping, plus materials and process development. Molded parts passed a battery of rigorous physical tests.

Teamwork key to successful development

Program success is attributed to focused effort by members of the European transportation-composites supply chain. Renault Trucks provided design work and supplied models for simulation, including full-scale designs of the complete truck, simulations for NVH and static and dynamic crash loads on the full truck. The company also provided interface-fastening development, supported Tier 1 manufacturing, and evaluated and tested full-size prototypes for front crash, durability and NVH, using its own verification and validation cab test rigs.

Tier 1 integrator/molder HBW-Gubesch Thermoforming GmbH (Wilhelmsdorf, Germany) contributed thermoplastic composites design expertise and processing recommendations to ensure part feasibility and manufactured all physical prototypes. It also developed the innovative molding process that ensures short molding cycles and reasonable tooling costs. Additionally, the company repurposed a compression press, built tooling and developed fixtures for post-mold bonding.

Solvay, through its R&D center in Saint-Fons, France, supported OEM design and full-scale static and dynamic crash simulations and process feasibility work, contributed advanced material models, simulated mechanical performance as well as bonding/assembly, and performed correlation studies to validate simulation accuracy vs. physical parts. Furthermore, Solvay developed and supplied two composite materials specifically formulated for the molding process.

Adhesives supplier Sika (Baar, Switzerland) contributed adhesive material models for Solvay’s simulation work and specified and supplied adhesive to ensure compatibility between composite and chassis components. By bonding the module to the chassis, fastener part count and part weight were reduced, and internal part stresses were reduced. Fastener supplier Wilhelm Böllho GmbH und Co. KG (Bielefeld, Germany, through its subsidiary in La Ravoire, France) made recommendations and supplied fasteners for the program, and provided additional prototyping support.

Material/process selection and design validation

As is often the case when composites must replace stamped metal at lower weight but comparable or higher mechanicals, consortium members were restricted to the basic geometry and design/packaging space of the benchmark bulkhead. Therefore, they were unable to adopt a “clean-sheet” approach that could take full advantage of the lightweighting, toughness, rapid-cycling, functional integration/parts consolidation, cost-cutting and recycling benefits of thermoplastic composites.

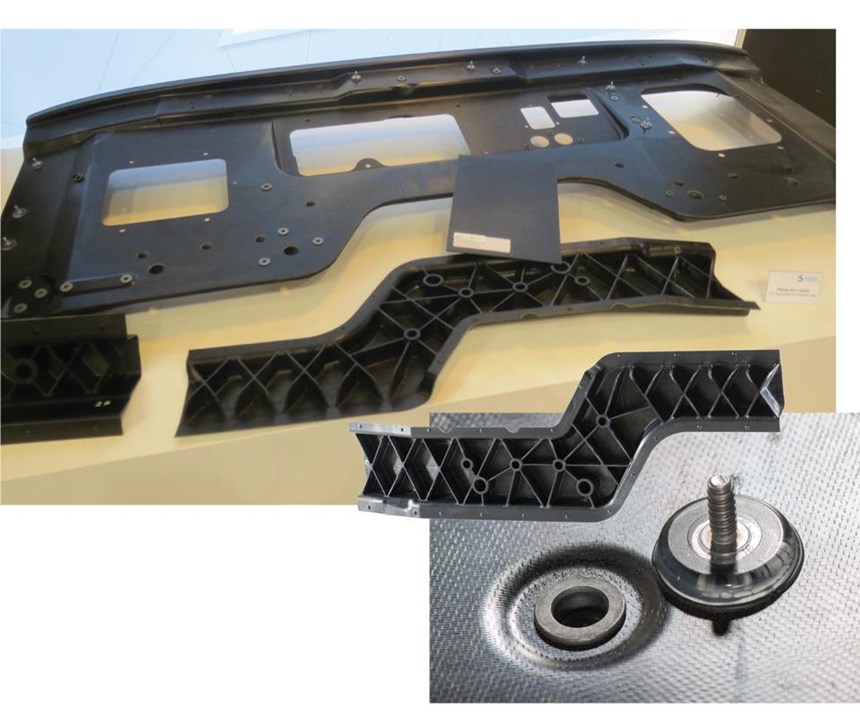

Nevertheless, the program’s goals were ambitious: Within the same tight space, replace the 1-mm-thick, 21-piece stamped-steel assembly (including multiple spot welds and fasteners) with a 3-mm-thick composite assembly that halves part count, reduces mass by 25%, improves performance and either reduces or maintains part cost. To meet performance and cost targets using a thermoplastic within the package space (which limited wall thickness), an impact- and chemical-resistant, thermally stable but cost-effective polymer, such as polyamide (PA), made more sense than either lower performing olefins or higher performing specialty polymers. Because much of the bulkhead’s design was a flat panel, sheet-form composites were a place to start. To maximize laminate stiffness/strength and impact-resistance at reasonable cost, continuous glass fiber reinforcement was selected. However, to meet mechanical performance in critical areas without significantly increasing wallstock, ribs were crucial. Unfortunately, continuous fiber materials don’t penetrate ribs well, so a second, discontinuous/chopped-fiber composite, which offers high impact resistance and high flow, was necessary. To ensure both composites were compatible, similar resin systems were used in each. Although organosheets don’t require a high-flow resin, one was used to ensure compatibility with ribbed sections. In the end, the panel’s main (flat) portion used 50% by volume balanced- weave glass fabric-reinforced Evolite high-flow PA6 organosheet, and ribbed sections used 30% (by weight) short-glass, high-flow, impact-modified Technyl C246SIV30 PA6 resin.

To meet its 20,000-units/year production target without increasing part costs, the consortium needed a fast-cycling process. A modified compression molding process was selected because it can form parts with design complexity: It could shape and consolidate the organosheet and form the intricate ribs without excessive machine or tooling costs. But because the team wanted to mold the organosheet (characterized by limited resin flow) and the high-flow, short-glass rib material in one process, an intermediate processing step was needed to convert the pellet-sized short-glass rib material to a form that would work in the press. Adding an extruder to the press to plasticize the short-glass material, however, was too costly. Even if it weren’t, the high-flow compound would be difficult to handle and control in the tool. Instead, pelletized short-glass plates/plaques were injection molded separately, then reheated (via infrared oven) and transferred to the press to mold each ribbed section. (During the project, robots moved the organosheet from oven to press, but the injection molded plaques were moved and placed by hand.)

Because the development program’s tooling budget was limited, aluminum was used to build three two-sided tools. (One tool for the flat/organosheet portion, plus one each for the upper and lower ribbed sections, which were shaped differently. During part development, the molder’s press dimensions limited tool size, so each part was molded separately.)

To connect the three moldings to each other and to metal inserts (which help join the composite module to the truck BIW), an attachment method capable of managing coefficient of thermal expansion (CTE) differences between the thermoplastic and steel was necessary. A surface treatment and one-part polyurethane adhesive from Sika were used.

The resulting hybrid process — high-flow material plaques injection molded offline, then reheated, combined and remolded together in the compression press — produces large, complex parts at low cost. Although each press cycle required only 1 minute, the final process, including preheating and bonding, extended to approximately 5 minutes — but was well within production targets. With a larger press, multi-cavity hard tooling and increased automation, the process reportedly could support series production of 100,000 assemblies/yr.

To connect the module to the truck’s BIW, Sika’s surface treatment and adhesive were again used. The adhesive joined the bulkhead to the left and right A-pillars, chassis/ side member, floor, windscreen, cross-car beam and instrument panel. For extra crash protection, bolts join the bulkhead to the cross-car beam. To integrate the bulkhead with truck cabin components (e.g., pedals, steering column, wire harnesses, etc.), the team used structural Rivkle SFC (Smart for Composite) blind rivet nuts, which are specifically designed for composites, and nonstructural Onsert hybrid fasteners, which join mechanical fasteners to non-weldable materials, both supplied by Böllho.

Multiple iterations were done before simulation and testing predicted the ultimate design/material/process combination that would meet project goals. To check the correlation between simulations and test results, a quarter-scale mini-prototype was evaluated at Solvay’s lab. The adhesive assembly method also was checked. Results showed bonding contributed to crash performance and was critical to success, so the analyst worked closely with Sika to define an adhesive numerical model that improved analysis accuracy. To ensure anisotropic fiber distribution and high strength in ribs, microtomography was used to view fiber orientations. Data from this analysis were fed back into material models to increase simulation accuracy. Positive results led to production of full-size parts, which were assembled on a prototype truck and subjected to NVH, durability and crash testing. Again, results were compared to simulations to ensure correlation.

Promising results

The final part featured a rear organosheet panel measuring 1,980 mm wide by 1,200 mm high by 2.8 mm thick, plus short-glass fiber-reinforced upper and lower ribbed plates, each approximately 360 mm wide by 100 mm high by 5 mm thick. The bulkhead passed frontal crash tests (ECE-29 regulations for homologation of vehicles for passive safety) and met Renault Truck’s NVH and durability requirements, achieving a component Technology Readiness Level (TRL) of 6 — not yet ready for commercial deployment but demonstrating technical maturity and high capability. Further, it met stated program goals, achieving a 25% weight reduction, halving overall (composite/ metal insert) part count, and coming in with acceptable costs.

The part is not yet commercial — it is not E-Coat compatible and, therefore, would need to be installed on the BIW late in assembly. For now, researchers continue to evaluate ways to add it to the current vehicle assembly process and examine alternative designs. Nonetheless, Renault Trucks is said to be pleased with the program results and target costs. And the project won a 2016 JEC Innovation Award in the Automotive Structural Parts category.

“This project showed just how critical accurate design and simulation work is to fulfill OEM requirements for lightweight applications,” explains Cécile Demain, Solvay’s senior development engineer and consortium project manager, who conducted Solvay’s simulations. “Ths work was vital for building OEM confidence in the capabilities of the final composite design so the project could progress to full-size prototype testing.”

“This project was a completely successful story with our partner, Solvay,” adds Sylvain Delaire, BIW engineer, Renault Trucks. “We know this composite material has very good mechanical properties and significant weight-saving opportunities compared to steel. We now have much better knowledge about tooling simulation and how to achieve more accurate results with this new composite material.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)