Plant tour: Kanfit Ltd., Migdal HaEmek, Israel

Aerospace tier supplier Kanfit Ltd. is expanding, offering both composite and metal parts for applications in an expanding range of high-performance markets.

- Wind/Energy

- Cutting/Kitting

- Sustainability

- Carbon Fibers

- Out of Autoclave

- Molds/Tools

- NDI

- Machining/Drilling

- Materials

- Glass Fibers

- Plant Tours

- Fabrics/Preforms

- Pressure Vessels

- ATL/AFP

- Processes

- Epoxies

- Resins

- Aerospace

- Reinforcements

- Design & Tooling

- Autoclave

- Ketones

- Prepregs

- Curing

- Space

- Medical

- Materials Testing

Entrepreneurial spirit is alive and well in Israel. A case in point is Kanfit Ltd. (Migdal HaEmek, Israel), near the city of Nazareth. Founded in 1986 as a composite tool workshop by Shai Fine, an aeronautical engineer with extensive experience building military jets, Kanfit, today, is primarily a build-to-print facility, with some build-to-spec work. It makes both composite and metallic parts for what Shachar Fine, Shai Fine’s son and Kanfit’s executive VP of business development, marketing and sales, calls “fit-and-fly” assemblies. Its business focii include the aerospace industry, of course — military, commercial and general aviation — but also medical devices, and wind energy, racing and ground defense applications.

Doing it all with the best and brightest

“We are a one-stop shop,” says Fine, “and a zero-maintenance subcontractor.” By that he means that the company has the capability to make tools, perform prototyping, do first article inspection and, ultimately, serial production. Composite part production technology includes RTM, infusion, prepreg hand layup, wet layup and autoclave. Examples of parts run the gamut from cockpit and airframe structure and one-off medical devices to chaff and flare magazines (more on these below) and innovative tooling for prototyping.

Certifications include AS9100D and Nadcap. Says Fine, “Kanfit is the only company in Israel to hold Nadcap certification for RTM processing.” It has been in its current location for four years, in a 3,200m2 building that doubled its previous floor space, with metal part operations on the ground floor and composites processing on the upper floor. All laboratory capability, which is extensive, is in-house, for cost and lead-time advantage.

But Shachar Fine tells CW: “Our raison d’etre is to bring quality jobs to the north of Israel.” Among Kanfit’s 188 employees are native-born Israelis and immigrants from around the world, including Germany, Ethiopia, the US and former satellites of the Soviet Union: “Kanfit is a microcosm of the start-up nation,” explains Fine. “We believe we have the best and the brightest engineers here in Israel. This, combined with our nation’s chutzpah, is key to our success in this competitive business environment.”

Kanfit also works with the Technion — Israel Institute of Technology’s engineering school — providing jobs and internships for students to learn about tooling, composite design and materials. One area in which Kanfit supports the school is Formula SAE: “We help them design tools and parts, like fairings or driver seats, when they are here in our facility. We insist they make parts with their own hands, because we believe that enables engineers to design a better part. In CATIA, you can design everything, but in production, you find out you can’t make the part.” Kanfit also strongly supports workers with disabilities, says Fine, and has environmental programs in place.

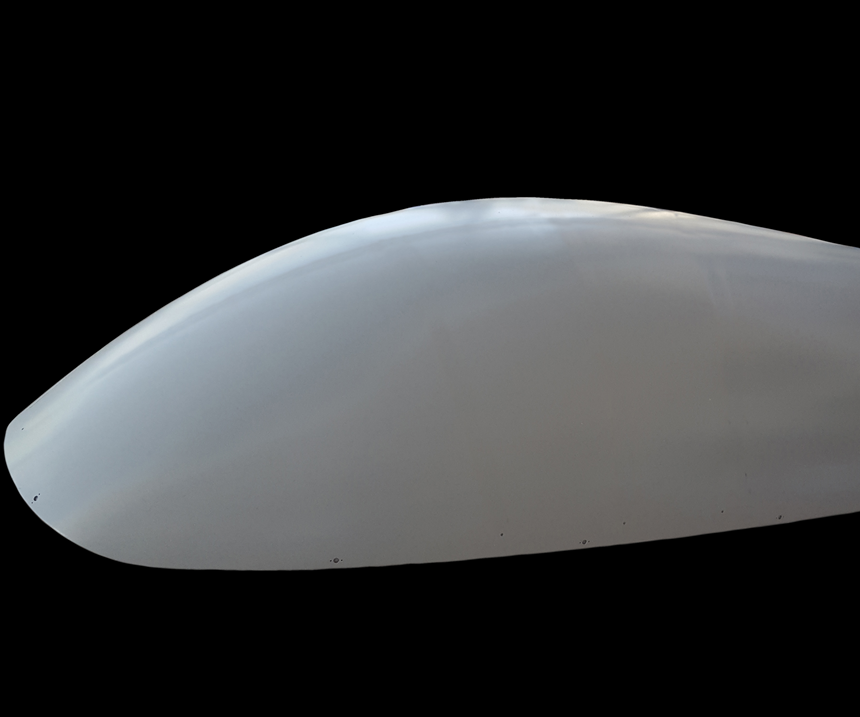

Kanfit’s diverse workforce makes an equally diverse mixture of composite and metal parts. For aerospace customers, these include wingtip fairings, wing-to-body fairings, wing-to-belly fairings, and main landing gear doors and radomes for business jet, military and defense projects. Some of these parts are honeycomb-cored, and Fine says more than 10,000 part numbers have been produced for those programs.

Kanfit is a Tier 2 (or lower) supplier to The Boeing Co.’s (Chicago, IL, US) 787; the Airbus (Toulouse, France) A380; Embraer’s (Sao Paulo, Brazil) ERJ and E2; Bombardier’s (Montreal, Canada) CSeries, CRJ, Global-series and Challenger; and Bell Helicopter Textron (Ft. Worth, TX, US). Other customers include Senior Aerospace UK (Rickmansworth, Hertfordshire, UK), Elbit Systems (Haifa, Israel), Zodiac Innovative Power Solutions (Eatontown, NJ, US), Plasan (Sasa, Israel), Israel Aerospace Industries (IAI, Lod, Israel), Rafael (Haifa, Israel), BAE Systems ROKAR (Jerusalem, Israel), BIRD Aerosystems (Herzliya, Israel) and ORBIT Communication Systems (Netanya, Israel).Kanfit also is a supplier to the Israeli Air Force (IAF) and Israel’s Ministry of Defense.

Further, Kanfit supplies several large but proprietary unmanned aerial vehicle (UAV) programs and, since 2013, has provided parts to the Israeli space industry, including a deployable dish for a satellite antenna. And, it has assembled numerous medical devices for several clients.

Kanfit is involved in considerable research and development activity as well and took delivery, in May 2018, of an automated fiber placement (AFP) machine from Ingersoll Machine Tool (Rockford, IL, US) with a robotic arm-mounted head. Fine says the machine was purchased for prototyping of highly complex parts: “Kanfit will be the location of Israel’s AFP National Center of Knowledge for automated composites processing.” He cites, as an example, a one-piece structural frame (more on this below) consisting of dry carbon fiber automatically placed over foam core, which is then processed via RTM. The frames are prototypes for commercial aircraft bulkhead frames.

Another R&D project involves a European program called EC Horizon 2020, and within that, a consortium called Hyperdiamond, which is developing a new cancer detection method, using nano-diamonds. The technology employs very powerful magnets, and the magnets must be held, or constrained, within strong yet lightweight composite jigs: “Composites were the enabler for this project,” says Fine.

One additional realm that Kanfit has entered is 3D printing, but at present, all of this work is done using metal powders, primarily titanium. The company employs an EOS (Krailling, Germany) machine, but Fine says Kanfit is working on integrating metals with composite materials going forward.

Organic growth, digital tools

CW’s tour begins in Kanfit’s quality control office, where an Instron (Norwood, MA, US) machine is used for coupon testing. Fine points out a small CNC machine where test coupons are cut: “We make test coupons with every vacuum bagged part for destructive testing.” Fine notes that Kanfit uses an artificial intelligence app called OKAPI (developed in Israel) to monitor key performance indicators (KPI), to help streamline workflow and make it more efficient. Along one corridor, charts are posted where employees’ KPI data are on display, which fosters some friendly competition.

Fine also gives CW a quick peek into a room filled with thousands of different types and sizes of fasteners. The “fastener guy” is responsible for preparing assembly fastener kits, just in time (JIT) for parts as they come from production. Along the same corridor, we see two composites cleanrooms, one for carbon fiber-reinforced parts and the other for glass fiber-reinforced parts. Barcodes are checked along the entire production route to document each part’s progress.

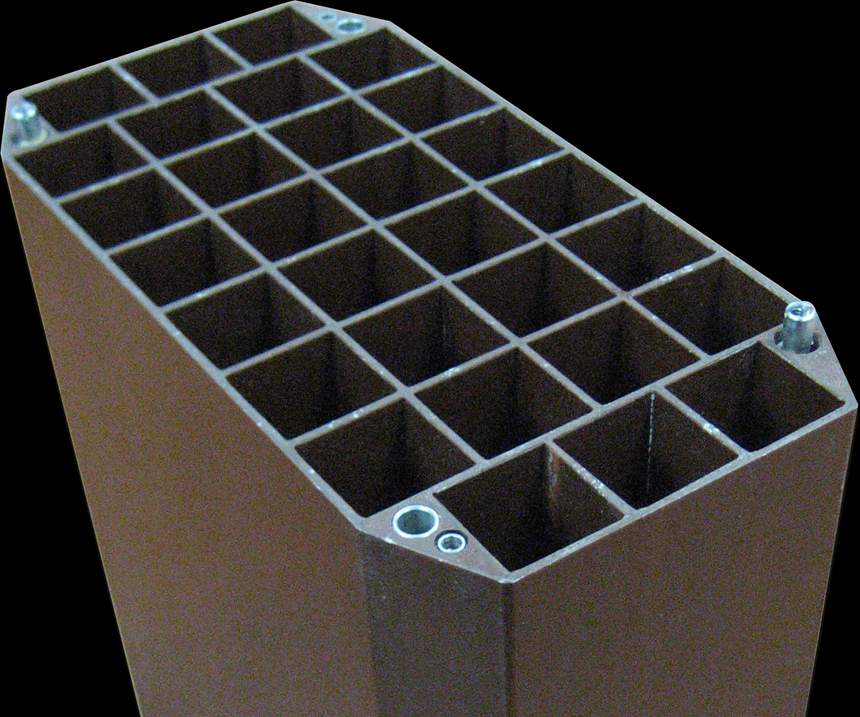

A new CNC machine, recently purchased for composite parts, is used, for example, to trim the chaff-and-flare “magazines,” or rectangular multi-cavity parts containers that are key components of the C-MUSIC commercial jet protection system. (See CW’s Elbit plant tour for a full system description.) It protects the aircraft against shoulder-fired missiles; chaff is a collection of small pieces of aluminum-coated plastic film that confuses radar by reflecting radio signals; flares are basically small fireworks that generate infrared signatures that confuse the infrared homing device). According to feedback received from the IAF, Kanfit’s chaff and flares have outperformed those manufactured by other companies. Kanfit reportedly has manufactured more than 8,000 chaff-and-flare magazines for use by air forces around the world, without a single reported deployment failure caused by manufacturing defect.

The CNC trimming machine helped reach that goal, says Fine: “We understand that in order to realize our goal of becoming the ‘supplier of choice’ to the international aerospace market, we need an edge over our competition and must provide added value for our customers. We’ll continue to in-source new technology processes that are needed for significant volume production.”

Fine then pauses before a second-floor display of composite parts, primarily for medical projects, including composite exoskeleton parts and rectal probes for prostate cancer (composites allow a thinner part). Also on display is a wing for a glide bomb. Fine says the wing is made with more than 100 plies of carbon fiber, which, although apparently excessive, is required to meet rigidity requirements: “We manufactured the wing using RTM and achieved 60% fiber volume.”

Another part on display was produced for use in heart surgeries and consists of an RTM’d glass/epoxy doughnut shape filled with copper coils aligned on the same plane. The device had to be produced to extremely tight tolerances (±0.01 mm). Says Fine, “We can reach a dimensional accuracy in our RTM processes of ±5 microns. We think it is an underused technology in the aerospace composites industry.”

Kanfit favors RTM because the use of dry textiles and injected resins rather than prepregs reduces Kanfit’s material costs and the process produces cured parts with acceptable void content much faster. Fine adds: “Autoclaved parts are overdesigned in my opinion — for instance, fairings which take very little load. We have moved parts from autoclave to RTM, which we see as basically an ‘autoclave for the poor.’ It offers so much flexibility, because the cycle time depends on the customer and the production rate needed. You can use heat and fast cycle time or room-temperature cure, whatever is needed to make the business case.”

AI-based workload management

Fine points out another time-saver. The production floor can handle about 4,000 work orders at any given moment. To help manage that work load, each work order, or traveler, has attached to it a Bluetooth sensor that connects with an artificial intelligence software system developed by Trekeye (Tel Aviv, Israel). A sensing system tracks all sensors, and the sensors issue alerts if the traveler is in the wrong place or has been misplaced. “We couldn’t use RFID tags,” says Fine, “because there is too much metal in the building. This system has really streamlined our entire production process.”

Next, CW visits the finished parts physical testing lab. The technicians in the lab point out that every autoclaved composite part undergoes inspection and nondestructive testing. Fine leads on, through the metrology area to the final inspection area, where parts undergo ultrasonic testing; two Olympus (Waltham, MA, US) A-scan machines are used for nondestructive testing (NDT), together with a FaroArm from Faro Technologies (Lake Mary, FL, US) and a laser scanner from Creaform Inc. (Levis, QC, Canada). Fine points out that Kanfit’s laboratory capabilities include physical properties testing (fiber volume fraction, void content, resin content, density), mechanical properties testing (short-beam shear strength, climbing drum peel, compression strength, tensile strength), and additional tests including flatwise, lap-shear, and 4-point bending.

Next on the tour is the machining area, where several Haas (Oxnard, CA, US) VF 4SS machining centers are installed. Another high-speed CNC router, which cuts a variety of materials in sheet form, was in operation, cutting ROHACELL foam supplied by Evonik (Marl, Germany). Forty part numbers can be nested during one cutting cycle, points out Fine. A sanding area and paint booth are located here as well, along with a chemical processing area for aluminum alodine (corrosion inhibitor) treatment. All water used in the metalworking steps is collected and recycled.

Next, the tour moves on to the newer autoclave building, an attached 850m2 structure that, Fine points out, is an entirely “green” building. That is, it uses passive systems for both heating and cooling, with no air conditioning required. Built 3 years ago, it houses the 5.5-by-2.1m ASC Process Systems (Valencia, CA, US) autoclave pictured on p. 28. An entire wall of photos in the building documents the delay-riddled, drawn-out process required to get the autoclave into the country, and into place in the building: “When the Port of LA labor strike commenced in 2014,” Fine recalls, “the autoclave was sitting on the dock awaiting loading and shipment to Israel. We were able to figure out how to truck the autoclave to the Port of Houston [TX, US] and get it on board a second cargo ship.” Fine says the company is ready to buy a second autoclave soon, because the first one is now operating almost at full capacity.

Here, in another cleanroom, rated ISO Class 7, with positive pressure, an Eastman Machine Co. (Buffalo, NY, US) automated flatbed cutter cuts plies and kits from material stored in the freezer nearby. Kanfit uses Plataine’s (Waltham, MA, US and Tel Aviv, Israel) nesting software for cutting. Aligned Vision (Chelmsford, MA, US) laser projectors mounted on the ceiling assist with kitting tasks and layup. Nearby, a new Belotti SpA (Suiso, Italy) 5-axis CNC machine is used for trimming, drilling and machining tasks, for both tools and composite parts. The x/y/z work envelope is 5 by 2 by 1.6m. The tool preparation area is adjacent to the ASC autoclave.

Continued expansion

The tour returns to the building lobby, where hundreds of parts are on display. “Hybrid structures are the future of composites,” states Fine, noting that composites combined with metals, for example, in the company’s complex business jet flight deck structure, enable large, complex drop-in assemblies. Kanfit’s business, he adds, is 40% composites and 60% metals, with the composites side increasing faster than the metals at a rate of 10% CAGR. Kanfit’s growth areas are aerospace, defense and medical, especially electromagnetic application structures (radomes and medical parts).

Notable among the other parts on display is a carbon composite CT scan tube of patented design, which Fine says contains “many trade secrets.” A quartz fiber/epoxy radome, made with ox-core honeycomb, was developed for a proprietary military customer. Also on display: a composite VOR (radio signals in the range of 108-117.95 MHz) antenna for a commercial client; Fine says the antenna metallic parts can be easily embedded in the composite laminate. “We were able to offer the client improved antenna performance at 40% lower cost than the original metal-centric design, at the same weight,” he adds. This antenna was on display at the recent Society of Manufacturing Engineers (SME) AeroDef conference in Long Beach, CA, US.

Concludes Fine, “We are growing ..., and we’re actively pursuing new technologies. For example, with the new Ingersoll robotic AFP, we can change the head and lay thermoplastic material, and change back to thermoset. We intend to keep expanding and will build another building within the coming three years.”

Related Content

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreOwens Corning initiates review of strategic alternatives for glass fiber business

Owens Corning considers alternative options like a potential sale or spin-off as part of its transformative move to strengthen its position in building and construction materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More