CW Blog

CW Talks catches up with Chuck Miller

The founder of tooling board manufacturer Coastal Enterprises explains how he went from engineering solutions for the the Saturn V rocket launch vehicle in the mid-1960s to making polyurethane boards for tool proofing.

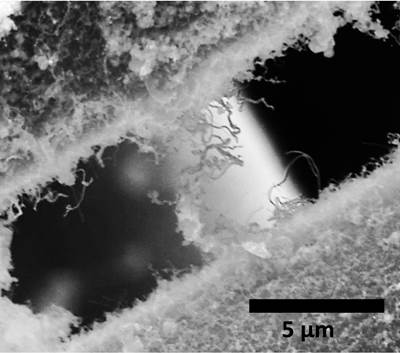

Read MoreEpisode 15: Joe Sprengard, General Nano

Joe Sprengard, president and CEO of nanomaterials specialist General Nano, talks about carbon nanotubes, the company’s work with Boeing and more.

ListenNew online Knowledge Base can help with mold release questions

A new online resource about all things mold release was recently announced by Stoner Molding Solutions (Quarryville, PA, US).

Read MoreCompositesWorld 2018 Operations Report

CW’s inaugural Operations Report aims to shed some light on the state of composites manufacturing today, and how it might evolve.

Read MoreA partnership for sustainable composites

CW talks to Entropy Resins and Gougeon Brothers about their future as one company.

WatchFold-to-form CFRP battery boxes, HP-RTM wishbones

Williams new EV platform demos 223 composite forming process and £20 suspension arms using recycled carbon fiber.

WatchComposite in Netherlands tunnel firewater system

The A2 motorway used to run through Maastricht. Now it runs under it. Composite piping helps make sure the tunnel’s firewater system is always ready.

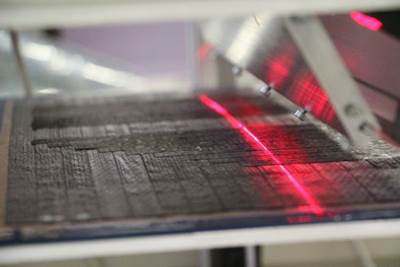

Read MoreYes, you clean tooling board with dry ice

Coastal Enterprises and Cold Jet cooperate to assess the use of dry ice blasting to clean the contaminated surface of a high-density urethane tooling board material.

WatchZero-defect manufacturing of composite parts

ZAero project aims for 30-50% boost in productivity via inline AFP inspection, simulated part performance and decision support tools.

WatchHybrid composite materials: tailoring for specific performance

I received a link to an interesting technical paper presented at CAMX by AGY (Aiken, SC, US). It got me thinking about hybrid composites.

Read MoreEpisode 14: Chuck Miller, Coastal Enterprises

Chuck Miller, founder and president of tooling board manufacturer Coastal Enterprises, details tooling board technology and how it continues to evolve.

ListenCW's top 10 digital content of 2017

CW’s first list of 2018 is a simple one: The top 10 most viewed articles on the CompositesWorld website in 2017.

Read More