CW Blog

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

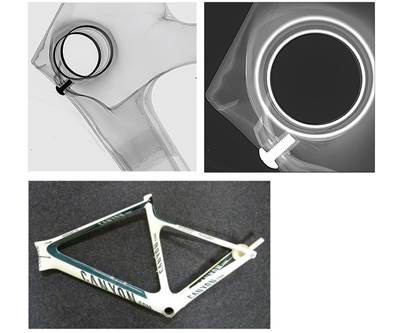

Read MoreX-rays for NDT of composites

Nondestructive test (NDT) methods can be employed during the design, manufacture and in-field maintenance of composite components.

Read MoreInfrastructure and construction — credit where due

Aerospace and automotive dominate the headlines, but one needs to take a wider look sometimes.

Read MoreMaterial supplier, manufacturer marry in oil and gas

Victrex and Magma Global, which have a long history of cooperation in the oil and gas industry, inched closer together with Victrex taking a minority interest in the composite pipe manufacturer.

Read MoreLexus' new sport yacht concept featuring CFRP construction

The Lexus Sport Yacht concept’s unique CFRP construction reportedly saves nearly 2,200 lb compared to a similar yacht in fiberglass reinforced plastic (FRP).

Read MoreHydraulic hybrids: Boosting fuel economy without batteries

Carbon fiber helps to lightweight hydraulic accumulators, increasing efficiency in hybrid vehicles and myriad other applications.

Read MoreNew method developed for bonding thermoplastic composites

A researcher at the University of Twente in The Netherlands has reportedly developed a method for adhesion improvement in thermoplastic composites.

Read MoreComposites and the future of package delivery

Germany-based CIKONI combined carbon fiber, aluminum and sandwich-based materials to create lightweight, modular shelving for the Vision Van, developed by Mercedes-Benz Vans. Video included.

WatchSMC is on the upswing (and check out this design competition)

There’s a lot going on with sheet molding compound (SMC) right now, including a design competition for best SMC design, with the winner announced at Composites Europe.

Read MoreCW Plant Tour: Aeris Energy, Caucaia, Brazil

This young, up-and-coming wind blade manufacturer was founded to serve the Brazilian wind energy market, but it’s poised to do much more.

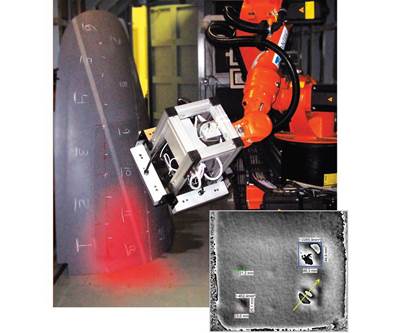

Read MoreAutomating NDT for CFRP aerostructures

Robotic laser shearography enables 100% inspection of complex, flight-critical composite structures.

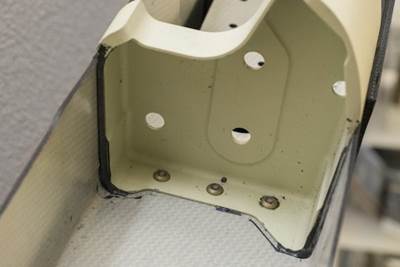

Read MoreOOA composites in next-generation launch systems

As United Launch Alliance ULA replaces Atlas and Delta with next-generation launch rockets under the Vulcan name, supplier Ruag Space has been selected to provide lower cost/improved quality out-of-autoclave fabrication of Vulcan’s composite primary structures. Ruag will manufacture 5.4m payload fairings and 400-series interstage adapters for ULA’s Atlas V rocket.

Read More