CW Blog

More and more composites blowing in the wind

Wind energy is putting the uncertainty that was the hallmark of this industry in the rearview mirror. Electricity from this renewable resource is cheaper and more competitive than it's ever been — and getting more so. This massive consumer of composite materials has a bright future.

Read MoreClear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

Read MoreBionic design: The future of lightweight structures

Biomimicry evolves into a systematic design process for optimizing efficient, lightweight structures.

WatchThe steadily growing list of IACMI resources

IACMI, the public-private composites consortium, is a little more than a year old and already has developed a strong collection of partnerships, facilities, equipment, software and material designed to help accelerate new technology development for the composites industry.

Read MoreVartega shows positive results of recycled carbon fiber testing

US-based Vartega Carbon Fiber Recycling has begun characterization of its material, and has received a letter of support from Janicki Industries, which will start to assess the fiber as well.

Read MoreGraphene edges closer to widespread production and application

New process may open door for mass production of high-quality nanomaterial targeted to replace copper mesh on composite aircraft.

Read MoreSandwich structure makes hangars possible

Greek company Dasyc has developed the high-strength Composite Modular Transportable Hangar (CMTH), which uses interlocked composite sandwich panels to ease assembly and disassembly.

Read More2016 Farnborough International Airshow Report

Composites are not the novelty in aerospace that they once were, but there was still much to see at Farnborough this year.

Read MoreAdditive manufacturing comes to composites fabrication

The use of continuous fiber in additive manufacturing systems is not trivial, but it is being done. As this fabrication technology evolves and matures, options for applying it in everything from automotive to aerospace to consumer composites will expand tremendously, creating a host of new opportunities for the composites industry. Read here for who is providing what kind of additive manufacturing technology for use in composites fabrication.

Read MoreSizing for carbon fiber

This sidebar to CW's August 2016 feature story on sizings for glass fiber outlines the current thrust of inquiry into sizings for carbon fibers.

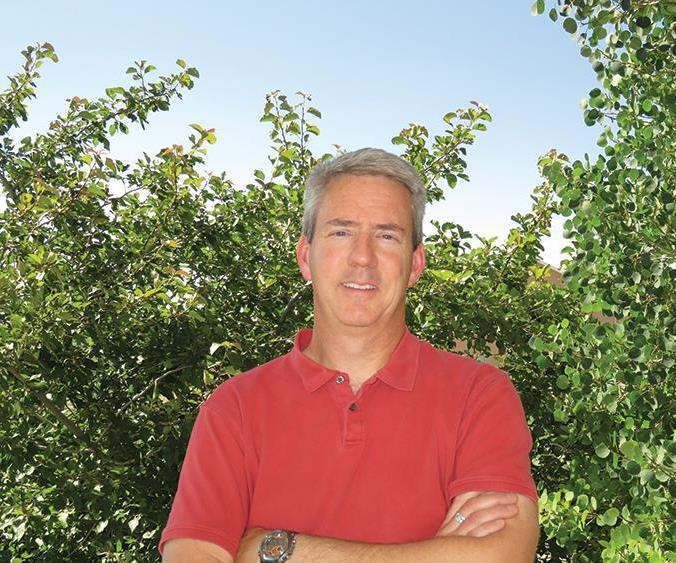

Read MoreImagining the utility of IoT in our increasingly data-driven age

CompositesWorld's editor-in-chief Jeff Sloan imagines one potential outcome of the Internet of Things: inline composite part inspection.

Read MoreComposite tanks best stainless steel over road, rail and sea

One-piece, filament wound containers cost less, hold more, last longer.

Read More