CW Blog

Nanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

Read MoreNot your average carbon fiber part

A Swedish industrial designer and artisan, Ragnar Friberg, contacted CW recently about a new project: a one-of-a-kind custom champagne glass and an accompanying storage cabinet that incorporates carbon fiber — along with a number of high-end materials.

Read MoreCooperating on new-generation ground transport

CompositesWorld's editor-in-chief Jeff Sloan shares his observations about the mixture of excitement and anxiety about the future of composite in the auto industry on display at the recent Thermoplastics Composites Conference for Automotive (TCCA), held in the Detroit suburb of Novi, MI, US.

Read MoreBoeing 787 assembly aided by automated positioning/joining

Massive composite components mated via motion control software.

Read MoreTrace: A simple, must-have tool

This recently discovered constant in laminate calculations can put designing with CFRP materials on par with designing with metals.

Read MoreBearing testing of composites

CW columnist Dr. Dan Adams (Wyoming Test Fixtures, Salt Lake City, UT, US) reviews the available options for testing the bearing strength of mechanically fastened composite joints.

Read MoreGet ready for Composites 4.0!

It might seem like science fiction, but it must be our path if we are to make composites competitive.

Read MoreCovestro kicking the tires on polycarbonates for automotive

Although development work has only just begun, the company's Makrolon polycarbonate, in a carbon fiber-reinforced composite, is proving highly impact resistant and offers a Class A surface.

Read MoreMassive Stratolaunch nears completion

Paul Allen's Vulcan Aerospace is working with Scaled Composites to build the largest aircraft yet made, and it uses a lot of composites. The plane, it is hoped, will deliver satellites into low-Earth orbit — affordably and efficiently.

Read MoreTaking the hand out of hand layup

Hand layup has a long history in aerospace composites fabrication, but it's not well suited for automotive composites manufacturing, where volumes are much higher. But the discrete placement of fiber reinforcements still has value. Research is pointing toward automated hand layup that might help this process bridge the aerospace-to-automotive divide.

WatchComposites help bring Shanghai Disneyland’s Tomorrowland alive

Many sections of both the interior and exterior of the buildings and rides were made from fire retardant gelcoated FRP composite molded parts.

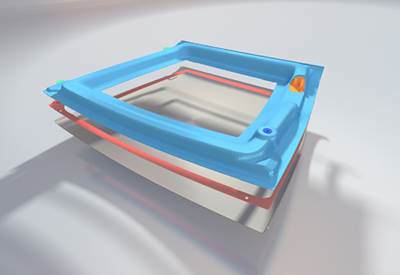

Read MoreGetting real: Thermoplastic resin transfer molding

KraussMaffei is launching this fall thermoplastic resin transfer molding (T-RTM), through which caprolactam is injected into a preform and then in-mold polymerized to create polyamide 6.

Read More