CW Blog

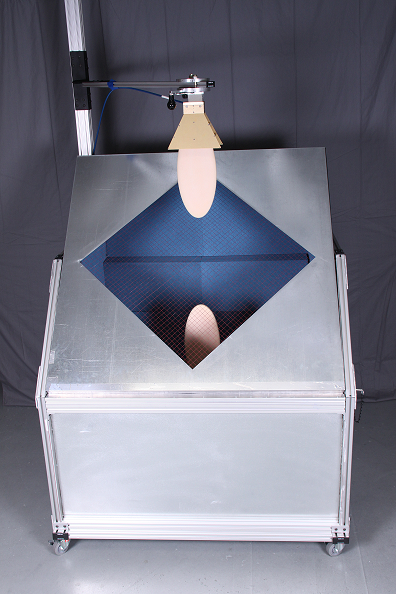

Dielectric properties measurement drives this NDT system to composites market

Material-Wave Interactions Laboratories (MWI Lab, Tempe, AZ, US), a 2010 spin-off of nondestructive material inspection technology developed at Arizona State University (Tempe), is coming off a period of substantial R&D and is preparing to put its product into the composites fabrication and maintenance and repair market.

Read MoreEuropean 2015 offshore wind mid-year growth tops previous full-year record

According to the European Wind Energy Assn.’s (EWEA, Brussels, Belgium) mid-year report, “The European Offshore Wind Industry — Key trends and Statistics, 1st Half 2015,” wind farm operators there installed more new capacity in the first half of 2015 than in all of 2014.

Read MoreCNT-enhanced prepregs: commercial & production-capable

N12 Technologies’ NanoStitch and Surface Layer System (SLS) products are part of a new generation of nanomaterials aimed at delivering macro-level benefits in products produced at commercial scale.

Read MoreReport from IBEX 2015

As always, IBEX supplied new products, processes and education, not only to boatbuilders, but to the composites industry overall.

Read MoreCFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

Read MoreCAMX 2015 Preview

ACMA’s and SAMPE’s 2nd combined event promises a conference and exhibition of unprecedented scale and value to composite manufacturers from all corners of the composites world.

Read MoreBioresins: Not a tsunami, but more like a rising tide

This excerpt from an upcoming article in CW magazine shows that a lot of investigation is happening, and some promising applications are developing.

Read MoreSuper "skinny" water skiff

Hell’s Bay Boatworks’ (Titusville, FL, US) latest design for a sportfishing customer does an unprecedented job of shaving weight and boosting toughness of flatboats for shallow-water operation.

Read MoreReformable composite equestrian saddle

This carbon fiber/polyethylene terephthalate (PET) saddle tree features an intralaminate heating element that enables horse owners to reconfigure saddle shapes as horses grow, greatly reducing long-term saddle-fitting costs.

Read MoreV-notched shear testing of composites

Dr. Daniel O. Adams, professor of mechanical engineering and director, for 18 years, of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US), reviews the most popular V-notched shear test methods for composite materials.

Read MoreIs a composites technical talent shortage looming?

Regular CW columnist Dale Brosius, also the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), calls for more schools with curricula that mint engineers with undergraduate degrees in composites.

Read More