CW Blog

Multifunctional composites: past, present and future

Dr. Les Lee at the Air Force Office of Scientific Research and Dr. James Thomas at the U.S. Naval Research Laboratory give insights into the history of multifunctional composites, the drivers for their development and where they are headed.

Read MoreTerma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

Read MoreClassic Reflections Coachworks: Tacoma, WA, US

They didn’t invent the wheel, but they take pride in reinventing — via high-quality CFRP and precision manufacturing — newer-model Corvettes with exteriors inspired by iconic Corvette stylings from this classic’s early days.

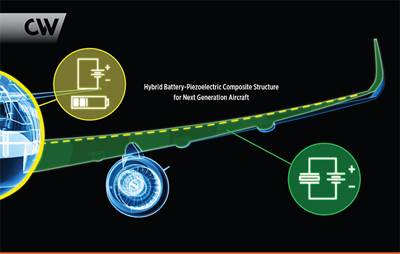

Read MoreAerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

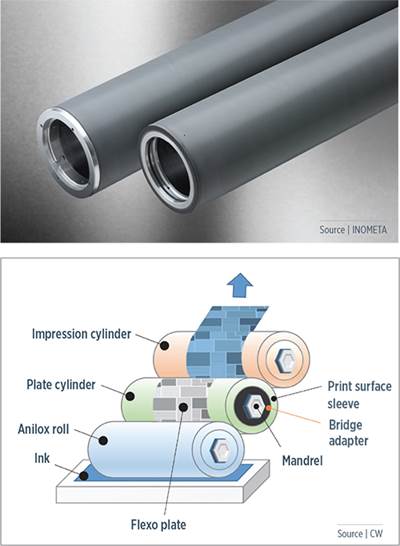

Read MoreCFRP adapters deliver high-quality printing at lower cost

Filament wound, carbon fiber/epoxy cylinders meet customer performance demands.

Read MoreHybrid analysis: Making the most of FEA by leveraging traditional analysis

CW guest columinst Collin Petersen (Janicki Industries, Sedro-Woolley, WA, US) suggests the use of more traditional analysis methods, where it is sensible to do so, making your finite element analysis (FEA) significantly simpler in the process.

Read MoreIs it time for carbon fiber manufacturers to cooperate?

In anticipation of CompositesWorld's 2015 iteration of its annual Carbon Fiber conference, set for December, CW editor-in-chief Jeff Sloan looks ahead to the future as he recalls some tough questions about carbon fiber standardization posed by last year's keynote speaker.

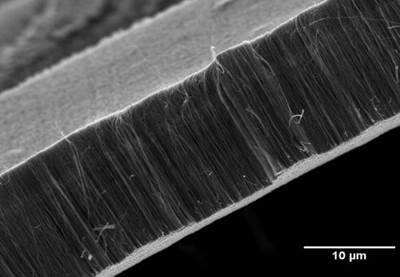

Read MoreThe end of delamination?

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

Read MoreCytec gearing up for automotive expansion

With a new automotive-focused Application Centre set to open in December, Cytec Industrial Materials is emphasizing material and process flexibility to help OEMs integrate composites into forthcoming cars and trucks.

Read MoreNew 250°F/120°C No Oven No Autoclave epoxy

Designed for room-temp infusion and filament winding with 2-hr no-heat-added cure or 15-30 min heated cure without post-cure for flexible processing of marine, industrial and energy structures.

Read MoreInfusion enthusiasm

Although CW didn't attend the EAA AirVenture in Oshkosh in 2015, we did learn about an infusion demo that was the largest ever accomplished at the fly-in event.

Read MoreGeneral aviation heats up at Oshkosh

The Experimental Aircraft Assn.’s (EAA) 2015 AirVenture Oshkosh drew an estimated 550,000 visitors, 2% more than in 2014, and recorded more than 10,000 show-related aircraft arrivals and hosted 2,668 official showplanes and 800 exhibitors.

Read More