CW Blog

Stratasys, Champion Motorsport team up to test 3D-printed core technology

Stratasys proves out carbon fiber-wrapped, printed core for toolless, customizable manufacture, on aerodynamic prototype and production parts for a winning racecar.

Read MoreCW Trending: The CompositesWorld Video Series

The composites industry is constantly being shaped and reshaped by myriad forces all stimulating innovative new ways to apply fiber-reinforced materials. CW Trending is a monthly video series that takes a closer look at these composites forces at these ideas, technologies, trends and innovations in development or already in the marketplace.

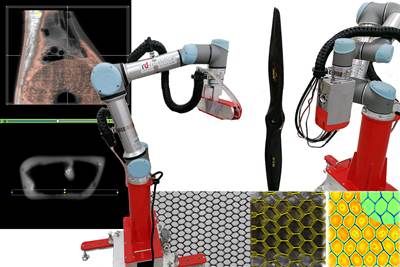

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

WatchComposites opportunities in a growing infrastructure market: CW Trending episode 2

This episode of CW Trending, sponsored by Composites One, takes a look at the opportunities for expanded use of composites in infrastructure applications.

WatchComposites in aircraft fuselage — now and in the future

What do some of the challenges of composites use on the 787 teach us about composites use on next-generation aircraft?

Read MoreCW Trending: composites opportunities in a growing infrastructure market

Learn from Editor-In-Chief, Jeff Sloan and guests Joe Fox and Gareth Williams about the trends they are seeing in the democratization of composites.

WatchAtmospheric plasma jet technology rapidly pretreats glass fiber honeycomb sandwich panels

Plasmatreat’s Openair-Plasma system provides composite honeycomb panel manufacturer, MonoPan Composites, with a reliable, high-speed and low-cost dry pretreatment solution for homogeneous wettability.

Read MoreTroubleshooting thermoforming of thermoplastic composites

Challenges with the thermoforming/stamping process and potential solutions addressing the associated parameters and complex material behaviors.

Read MoreLeveraging large-format AM fuels aerospace flexibility

Ascent Aerospace is known for producing high-quality metallic molds and tools for large aerostructures. Investment in large-format AM has expanded the company’s capabilities.

WatchComposites manufacturing is additive manufacturing

As the additive manufacturing space continues to expand, it might be the technology that catapults composites fabrication itself.

Read MoreDLR ZLP demonstrates new method for thermoplastic composite hydrogen fuel tank

AFP uses xenon lamp heating and inline QA to achieve innovative design which also uses ultrasonic welding.

WatchComposites AM research targets wind energy

The U.S. DOE, universities and industry leaders ramp up new efforts and funding to develop 3D-printed composite wind blade molds and end-use blade components.

Read More