HexPly M901 prepreg accelerates product development cycles

Hexcel’s HexPly M901 prepreg system reportedly reduces production time of composite leaf springs.

Read MoreTrelleborg undertakes composite-based R&D project

The focus of the project is to develop a novel composite material that can be integrated into an EV battery to reduce the overall weight of the battery case.

Read MoreSamba Step system expands composites research for Augsburg University

Germany-based university intends to use Cevotec’s FPP-based Samba Step system for field research of ceramic fiber composites.

Read MoreACS, Susta and U.Form partnership creates CarbonForm network

Collaboration will lead to the development of press forming technologies using composite materials.

Read MoreGE Renewable Energy to expand wind blade facility in Gaspé

A partnership with Canada and Québec will enable the company to expand its existing facility and will result in the creation of 200 skilled jobs.

Read MoreLockheed Martin opens new facility, expands Orion spacecraft production

The STAR Center provides space for the new production phase of Orion, allowing future Orion spacecraft, beginning with the Artemis III mission, to be built faster.

Read MoreEpic Aircraft receives FAA type certification for E1000 GX aircraft

The new E1000 GX is equipped with the Hartzell five-blade composite propeller, offering improved performance, safety, comfort and versatility.

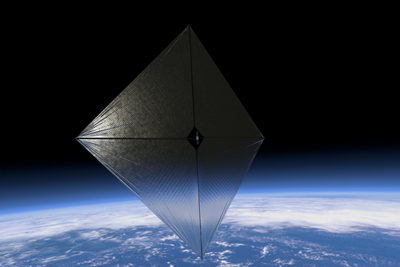

Read MoreNASA develops advanced composite solar sail system

The ACS3 mission expects to demonstrate the successful deployment of the composite boom solar sail in low-Earth orbit to guide the design of future, larger-scale composite solar sail systems.

Read MoreVoltAero selects new facility for hybrid-electric Cassio aircraft

Construction is expected to begin in the second quarter of 2022. At full rate, VoltAero anticipates producing approximately 150 Cassio aircraft per year.

Read MoreAirbus begins assembly of the A321XLR nose and front fuselage

Coming less than two months after the start of assembly of the rear and center fuselages, this marks another significant production step for the A321XLR.

Read MoreEastman Machine begins headquarters expansion

The 7,500-square-foot expansion of Eastman’s facility will provide more capacity to accomodate a robust demonstration and research center for its composites cutting technology and solutions.

Read MoreCevotec fiber patch placement improves storage efficiency of composite tanks

Cevotec’s solution is to apply carbon fiber patches to the dome areas of Type IV pressure vessels, which reportedly yields 15% in material, weight and cost savings.

Watch