Kanfit installs new autoclave, automated cutter to increase composite parts production capacity

Composite parts producer in Israel increases capabilities for composites, 3D printing and hybrid assemblies.

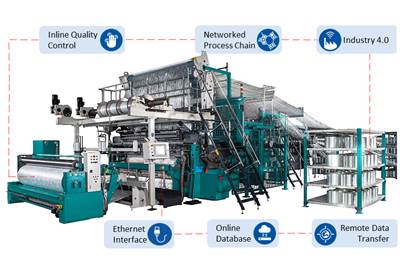

Read MoreITA acquires composites 4.0-enabled BIAXTRONIC warp-knitting machine from Karl Mayer

This latest technology will aid development of open-meshed textile grids and non-crimp fabric structures for composites and concrete reinforcements.

Read MoreEuropean Commission issues call for clean aviation partnerships

Accepting proposals targeting hybrid electric and hydrogen-powered aircraft in 2 demonstration programs to deliver impact by 2030.

Read MoreRhode Island boat recycling program plans expansion to other states

Having recycled 60 tons of fiberglass in two years, the RIMTA program will expand to Conn., Mass., Maine and Wash. state via funding from the NOAA Marine Debris Program.

WatchC-FREX exoskeleton depends on CFRP for unpowered movement

C-FREX uses a novel design and CFRP to overcome the heaviness and weakness of metallic exoskeletons.

WatchLeonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

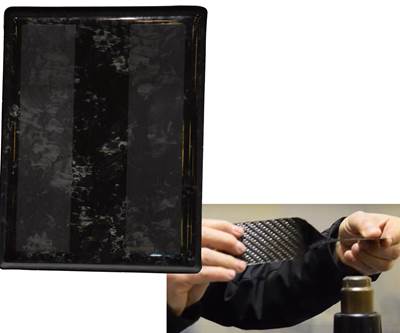

Read MoreThe industrialization of thermoplastic epoxy

Fast-processing composites that are strong yet tough, thermoformable, reformable, recyclable and even FST-compliant save cost in aircraft and rail equipment.

Read MoreElectroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

WatchFRP profiles enable affordable aesthetic solution for unique residential architecture

The FRP profiles, manufactured by Italy-based M.M. S.r.l., allow easy fabrication and construction on-site in less than two days.

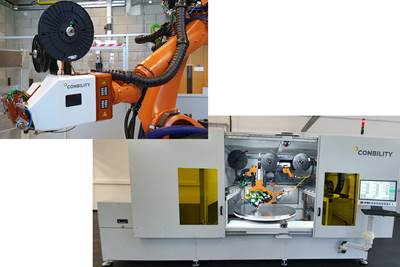

Read MoreConbility: Mass production of composite tape laminates

RWTH Aachen spin-off scales up production for low-cost, in-situ consolidated composites as inserts for lighter, cheaper injection-molded parts.

WatchComposites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

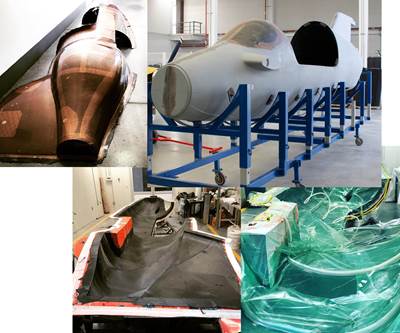

Read MoreFirst all-CFRP fuselage in Mexico

UNAQ and RHEM Composites help produce body of third prototype for Oaxaca Aerospace’s Pegasus P-400T.

Read More