Clean Sky 2 SHERLOC project advances SHM for composites

New video shows goals, framework, sensors and tests for more affordable, smart composite fuselage

WatchHydrogen theme day of Composites United e.V. is a big success

The European network’s “Hydrogen Storage — Opportunities for Fiber Composites” on Jan. 19, 2021 experienced more than 350 registrations.

Read MoreNovel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

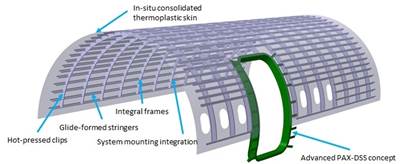

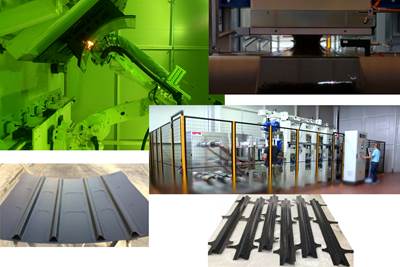

WatchManufacturing the upper half of the Multifunctional Fuselage Demonstrator (MFFD)

Proving industrial reliability for low-cost thermoplastic composites production using AFP in-situ consolidation, as well as continuous ultrasonic and resistance welding.

WatchZeroAvia secures additional funding to accelerate hydrogen-powered aviation

Amazon, Shell add to $21.4 million in venture funding plus U.K. government $16.3 million grant for HyFlyer II project to deliver 19-seat H2 aircraft by 2023.

Read MoreLingrove launches Ekoa Surface Peel N’Stick and receives automotive orders

Natural fiber/bio-thermoplastic composite veneers meet sustainability and performance demands for multiple markets.

Read MoreComposite rebar for future infrastructure

GFRP eliminates risk of corrosion and increases durability fourfold for reinforced concrete that meets future demands as traffic, urbanization and extreme weather increase.

WatchHydrogen fuel cell-powered HY4 aircraft takes flight

MAHEPA consortium demonstrates feasibility and advances toward liquid hydrogen tanks and scaling modular HY4 technology to new, emissions-free aircraft.

WatchMultilayer thermoplastic tapes, AFP and resin infusion for more democratic composites

Novotech advances new materials and more affordable automated processes for small aircraft and beyond

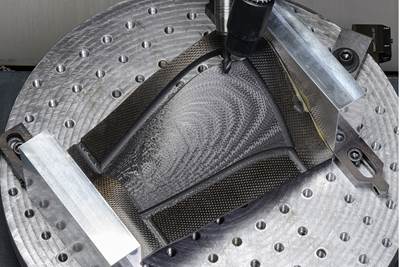

WatchFraunhofer IPT automates production of thermoplastic CFRP engine fan blades

Successful first demonstrations on 16-mm-thick CF/PA12 to be followed by CF/PEEK tapes and embedded sensors for structural health monitoring (SHM).

Read MoreFraunhofer IFAM automates pre-assembly of CFRP fuselage frames

Positioning and drilling end effector for automated, high-precision and quality-assured pre-assembly developed with Airbus in German-funded “Tempo” sub-project.

Read MorePratt & Whitney to produce advanced metal and CMC turbine airfoils in North Carolina

New 1 million-square-foot production facility follows CMC R&D center and publicized strategy for next-gen engines.

Read More