Turnkey manufacturing systems: Part-per-minute thermoplastic composites

Pinette Emidecau Industries’ (PEI, Chalon-sur-Saône, France) leads a consortium of providers that are collaborating on the Quilted Stratum Process (QSP), a means to accelerate thermoplastic composites processing in the auto industry.

Read MoreTurnkey manufacturing systems: Aiming for automotive-industry volume production

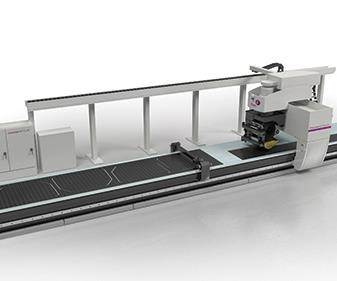

Fives Cincinnati (Hebron, KY, US) has announced an integrated manufacturing system for automotive composites comprising two automated manufacturing cells.

Read MoreTurnkey manufacturing systems: Simplifying automated HP-RTM

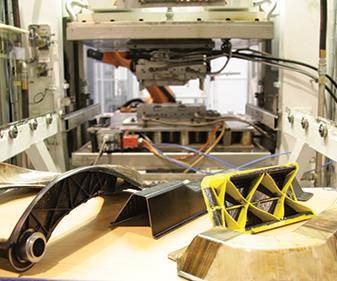

Having offered turnkey systems for composites since the 1990s for sheet molding compound (SMC), long fiber thermoplastic (LFT) and glass mat thermoplastic (GMT), Dieffenbacher (Eppingen, Germany) now has automated systems for high-pressure resin transfer molding (HP-RTM).

Read MoreTurnkey manufacturing systems: Automated RTM for aerospace

German Aerospace Center’s (DLR) Center for Lightweight Production Technology site in Stade, Germany, has developed EVo, an automated production line capable of 100,000 complex composite parts/yr.

Read MoreTurnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

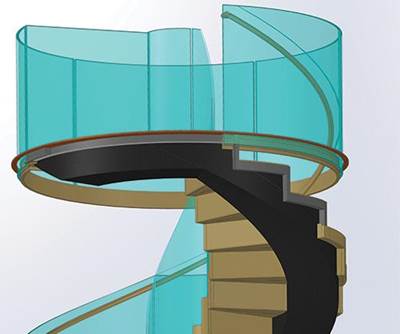

Read MoreStructural work of art

Composites fabricator uses an innovative molding approach and digital techniques to actualize architect’s customized residential stairway.

Read MoreCW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

Read MoreInfused trimaran takes to the seas

French shipyard CMN has released a video showing the Ocean Eagle 43 infused epoxy trimaran in action.

WatchReducing manufacturing cost via RTM

Airbus Bremen aims to replace dozens of prepreg components and assembly operations with a unitized multispar composite flap molded in a one-shot process.

Read MoreCMF project's process combines prepreg with RTM

Composite Multispar Flap (CMF) project at Airbus Bremen demonstrates SQRTM process for producing aircraft flaps

Read MoreNew technologies and companies at CAMX 2015

Final rundown of “finds” from CAMX, from technology for cutting composites and joining CFRP to metal for hybrid parts to companies offering training, textiles and NDT.

Read More