Increased competition from metals

Boeing and Airbus are developing new, lightweight, corrosion-resistant metals that are targeting composites' traditional niche in the material sphere.

Read MoreCAMX 2015: Eyecatchers

A selection of parts, processes and new players from the exhibit floor as well some interesting developments from the technical sessions.

Read MoreMultifunctional composites: past, present and future

Dr. Les Lee at the Air Force Office of Scientific Research and Dr. James Thomas at the U.S. Naval Research Laboratory give insights into the history of multifunctional composites, the drivers for their development and where they are headed.

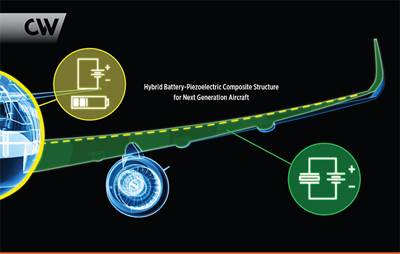

Read MoreAerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

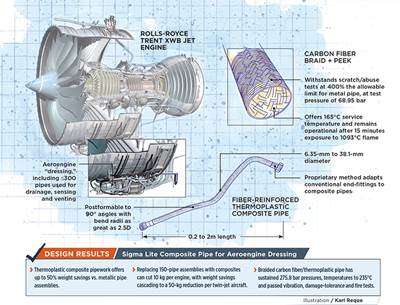

Read MoreRe-dressing aeroengines with composite pipes

Sigma Lite braided carbon fiber/thermoplastic pipe cuts jet engine weight yet meets challenging design and manufacturing requirements.

Read MoreComposite aeroengine dressing to wing driveshafts, SHM and more

For Sigma Precision Components (Hinckley, UK), composite pipe for jet engine dressing could be only the beginning.

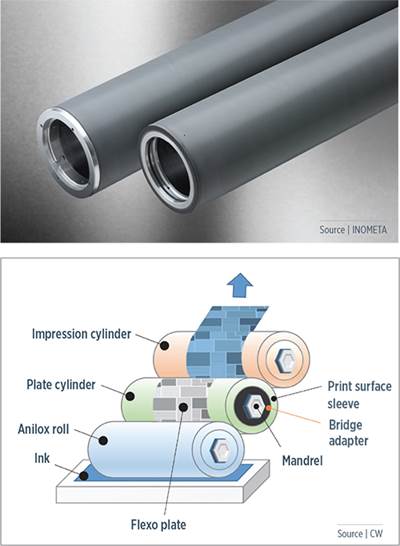

Read MoreCFRP adapters deliver high-quality printing at lower cost

Filament wound, carbon fiber/epoxy cylinders meet customer performance demands.

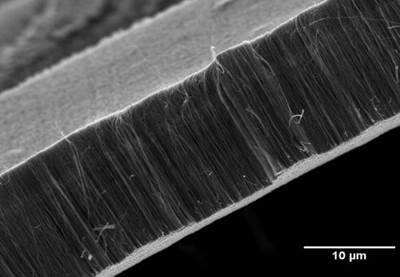

Read MoreThe end of delamination?

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

Read MoreNew 250°F/120°C No Oven No Autoclave epoxy

Designed for room-temp infusion and filament winding with 2-hr no-heat-added cure or 15-30 min heated cure without post-cure for flexible processing of marine, industrial and energy structures.

Read MoreNew low-cost, high-temp resins

MG Resins offer a suite of properties and processing that could potentially revolutionize sectors of the composites industry.

Read MoreOptimizing composite aerostructures production

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

Read MoreMaterials Sciences Corp.: Multifunctional composites

MSC draws on four decades of experience and computer modeling expertise to develop novel composite materials with the potential to make a big impact.

Read More