Resin infusion: Taking off?

Boeing Aerostructures Australia leads large-scale development of resin infusion as an industrial process.

Read MoreComposites help Bell V-280 toward Future Vertical Lift

Bell’s design for future military helicopter uses hybrid metal-composite construction and Large Cell Carbon Core technology for unitized wing.

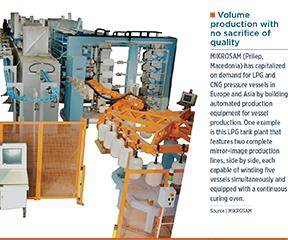

Read MoreAutomated filament winding enables competitive composite cylinders

Carefully controlled, robust, volume processes offer fabricators of Class IV LPG/CNG tanks a means to meet increasing demand in Europe and Asia.

Read MoreAircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

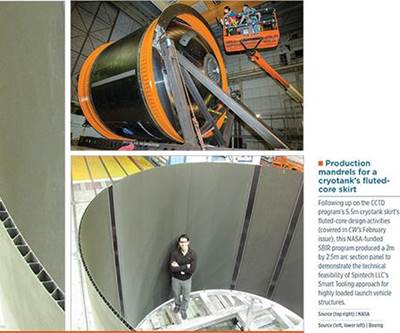

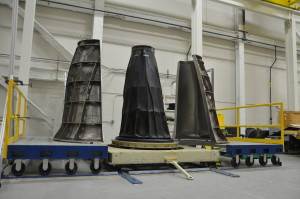

Read More“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read MoreInflexion technology: complex composites without fasteners

Spirit AeroSystems has developed production methods using rigid-flexible tooling for more affordable unitized composite aerostructures.

Read MoreRecycled carbon fiber proves its potential for aircraft interiors

An Airbus-led team characterizes RCF veils and shows their ability to best glass fiber composite sidewalls in cost, weight and surface finish.

Read MoreFiber patch preforms help tailor kiteboard performance

Automated means for laying fiber only where needed offers new potential to fine-tune torsional stiffness and flexibility to board and rider styles.

Read MoreDisruptive composite infrastructure

FiberCore Europe claims the "Holy Grail" of delamination-resistant FRP bridge and infrastructure components with its patented InfraCore technology.

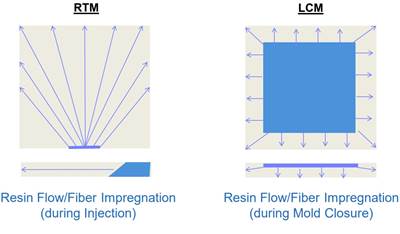

Read MoreWet compression molding

Automated process cuts cycle time and cost for CFRP parts with potential for 65% fiber volume via Dynamic Fluid Compression Molding variant.

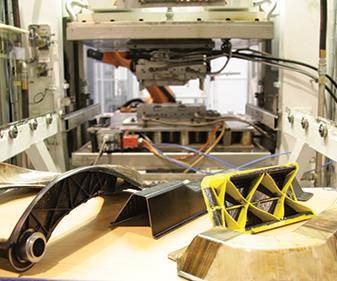

Read MoreTurnkey manufacturing systems: Part-per-minute thermoplastic composites

Pinette Emidecau Industries’ (PEI, Chalon-sur-Saône, France) leads a consortium of providers that are collaborating on the Quilted Stratum Process (QSP), a means to accelerate thermoplastic composites processing in the auto industry.

Read More