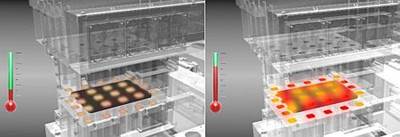

Pixelated temperature control

Surface Generation is providing digital process control for composites molding that cuts energy use, cycle time and processing pressures while breaking boundaries in thickness, complexity and embedded elements.

Read MoreVABO Composites: Dutch innovator excels in diverse applications

From yacht masts and ship doors to front loader buckets and architectural projects, VABO uses resin infusion and ingenuity to push composites forward vs. metals.

WatchNew hybrid solar energy system uses composites to lower costs

Patent-pending 5D Watts system increases solar energy production four times vs. conventional non-composite flat panels while lowering weight and installation cost.

Read MoreCost-effective aerocomposites: Dry fiber AFP and resin infusion

Aurora Flight Sciences and NONA Composites aim to improve toughness, repeatable aerospace quality and affordability for large-scale NASA structures.

Read MoreComposites in tornado shelters

A new design aims to defeat the threat from debris, both as heavy piles preventing exit and as projectiles traveling at ballistic speeds.

WatchCIBOR advances aerospace materials in medical applications

CFRP in surgical instruments and orthopedic implants gets assistance from Wichita R&D center.

Read MoreFull steam ahead for composite ship doors and hatches

VABO Composites (Emmeloord, The Netherlands) has added to its wide range of composite products these ship doors and hatches that offer a 50% weight reduction vs. conventional steel doors.

Read MoreDigital twin, digital thread and composites

How the integration of machines, sensors and software is beginning to impact composites manufacturing.

WatchFastener-free, composite aircraft door and control surfaces

All-composite, integrated structures using RTM cut weight and cost by more than 30%.

Read MoreCFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreComposites in exoskeletons

Wearable robotics need strength, stiffness and lightweight and are forecast at a CAGR of 40-50%. Will composites play a role or be left behind?

WatchLarge portable antenna goes lightweight with conductive composites

CFRP matches metal performance at one-third the weight thanks to innovative materials and precision manufacturing.

Read More