CAMX 2018: Big changes coming

3D printing goes thermoset, pultrusion aims at automotive, a polyester resin with Tg>250°C and much more from the Dallas exhibit floor.

Thermoset 3D printing

CW has reported widely on 3D printing composites using thermoplastic resins. But over the past year, we’ve seen growth in printing with thermoset resins (and continuous fiber, see May 2018 blog and Sep 2018 blog). This trend seems poised for further growth, with Large-scale Thermoset Printing displayed by Oak Ridge National Laboratory (ORNL) in the CAMX and ACE awards areas. Developed in partnership with Magnum Venus Products (MVP), the large-scale thermoset printing system called THERMOBOT has a build volume of 16 x 8 x 3.4 ft. By using reactive polymers that fully crosslink between layers, THERMOBOT technology claims to produce higher-strength printed parts vs. those with partially fused, thermoplastic layer. The cost of feedstock is also estimated to be 50% lower. All trials to date have used vinylester systems from Polynt-Reichhold, based on its Corporate Research and Development Agreement (CRADA) with ORNL.

|

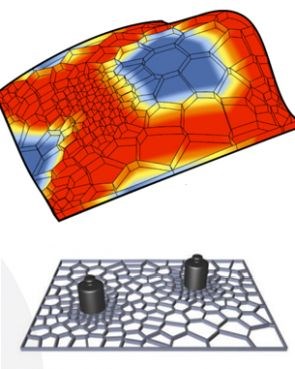

By putting more material where a structure must handle more load, honeycomb with varying cell diameters and heights can achieve significant weight savings while increasing stiffness.

SOURCE: ELiSE (left) and CW.

One strategy for the THERMOBOT technology (see images above) is to produce high loadbearing yet lightweight structures by printing variable-density cellular honeycomb structures that can be tailored per application. The result is faster printing of higher-strength structures which consume less material, time, energy and cost vs. current approaches. This may also offer the most cost-effective way so far to actualize load-adapted honeycomb structures, a bionic design approach introduced by Evolutionary Light Structure Engineering (ELiSE, see 2016 blog). MVP is pursuing a commercialization plan and welcomes inquiries.

SOURCE: CW

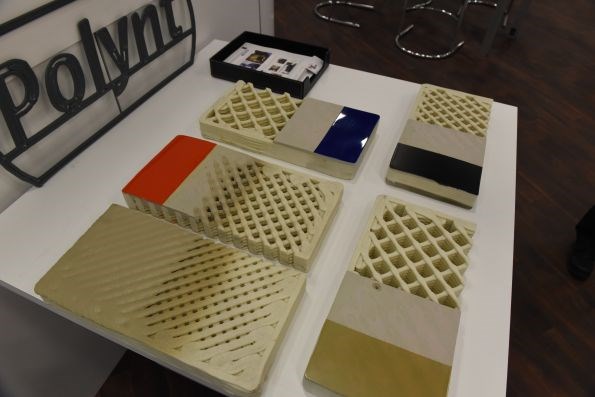

3D printed molds iterate again

Polynt-Reichhold, in partnership with Cincinnati Inc. and TruDesign (Knoxville, TN, US), displayed another step-change in 3D printed composite molds. The advance displayed at CAMX was printing molds not with a solid substructure, but with a lattice-type core, which reduces print time, material and cost. The actual mold surface is achieved by spraying the 3D printed lattice with TD Coat RT, a high-build, room temperature coating into which final dimensions and details are machined. This coating is applied with MVP spray equipment and is commercially available from TruDesign. Notably, it bonds the thermoset surface to the thermoplastic printed substrate, seals the surface for vacuum integrity and also handles the significant difference in coefficient of thermal expansion (CTE) between the machine- and z-directions of the printed composite — typically a 20% carbon fiber-reinforced ABS. Otherwise, changes in temperature may cause changes in the mold surface. The mold segments displayed above were printed by AES (Akron, OH, US) using a Cincinnati Inc. BAAM machine.

|

SOURCE: CW

L&L offers pultruded structures for automotive

L&L Products, Inc. has launched its Continuous Composite Systems (CCS) pultrusions using polyurethane resin. Aimed at automotive applications such as side sills and crash structures, they replace traditional metal structures that require bulkheads for necessary stiffness, offering lightweight — 75% less mass than steel and 30% less than aluminum — at an economic price. Continuous fiber profiles include CCS Set using glass fiber, CCS Hybrid using a customized mix of glass and carbon fiber and CCS Extreme using only carbon fiber. These composites may also be combined with L&L’s well-known adhesives as part of their continuous processing, further reducing manufacturing costs and time-to-delivery. Note that L&L adhesives are also used to help mitigate noise, vibration and harshness (NVH) issues. Beyond automotive, CCS products are also aimed at wind turbine blade spar caps, industrial and architectural applications.

L&L also displayed their torque retention isolation TRI-seal products for multi-material automotive bodies. Expandable sealant material is augmented with Alumina (Al2O3, or aluminum oxide) spheres, which supports clamp force for torque retention while providing isolation between dissimilar materials to prevent galvanic corrosion and sealing against water, air and dust intrusion, all at the same time. Either heat-bonded for dry applications or tacky for pressure-sensitive applications, TRI-seal products may be used at dissimilar material interfaces, bolted/riveted attachments and door/hood/lift gate hinges.

|

SOURCE: Owens Corning

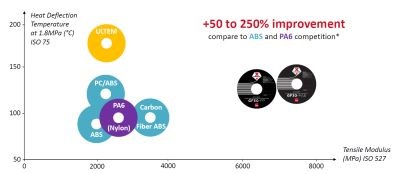

Owens Corning produces 3D printing filaments

XSTRAND 3D printing filaments have been developed using the company’s chopped glass fibers and polyamide 6 (PA 6 nylon) or polypropylene (PP) polymer. Why glass fiber? “It prints better, with a better finish and has better properties vs. chopped carbon fiber because we engineered a better solution comprising fiber sizing optimized for each type of polymer,” explains Owens Corning product expert Jay Yang. He notes significant product development and material selection were required to develop an optimized system of polymer, fibers and sizing. “This is not trivial and required out a lot of R&D work for two years.” Yang says more product variants are in the pipeline, including filament using higher temperature and more specialty polymers.

SOURCE: ATSP Innovations.

Polyester resin with Tg>250°C

ATSP Innovations (Champaign, IL, US) is a start-up from the University of Illinois at Urbana-Champaign that has developed Estherm aromatic thermosetting polyester (ATSP) resins. This reported new class of copolyesters offers higher performance than a typical polyester or average wet layup epoxy resin:

| Tensile strength | 95 MPa |

| Tensile modulus | 4.2 GPa |

| Compressive modulus | 4.9 GPa |

| Compressive strength | 304 MPa |

Yet it also touts a higher temperature capability (Tg>250°C) vs. polyesters and vinylesters, which max out at 140°C and 160°C, respectively, and epoxies which reach maximum service temperature before 200°C. ATSP Innovations reports that composites made with Estherm enable load-bearing structures up to a Tg of 285°C. This is actually more in line with phenolic (148-260°C), bismaleimide (200-282°C) or polyimide (260-316°C) resin systems. The company claims even further benefits including very low moisture pickup, oxidative stability, easy machinability (low dust), low flammability without fillers (limiting oxygen index of 40%, which is greater than phenolic) and recyclability akin to thermoplastics.

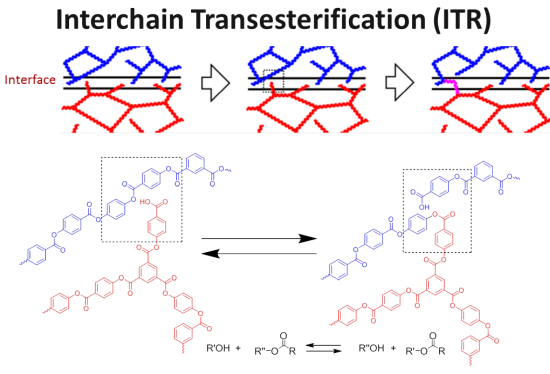

In fact, similar to L&L Products LF610 reformable epoxy adhesive, when this aromatic thermosetting copolyester is formulated into an adhesive (trademarked Self-Bond), it allows bonding and debonding, each with heat and pressure, which can be repeated 50 times without loss in strength. ATSP Innovations explains this is possible due to a solid-state bonding process called interchain transesterification reaction. Estherm and Self-Bond are reportedly drop-in solutions, which can be tailored to meet specific customer needs and are available in multiple product forms. ATSP Innovations has published research on processing the materials in composites and as foams, as well as tribological and cryogenic coatings. The materials have been in development since 2011 and ATSP Innovations was recently awarded a Phase II follow-on from its NASA-sponsored Phase I SBIR project “Reversible adhesion concept for in-space assembly”.

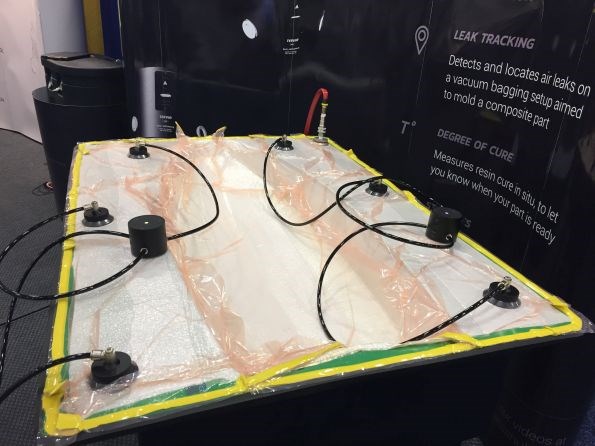

IoT for vacuum bag cure

Ruiz Aerospace (Laval, QC, Canada) has developed TERVIA Hub, embedded with sensors and internet connectivity, which enables collection of data from vacuum ports connected to the hub and exchange of that data via wifi using a phone, tablet or PC. The probes collect atmospheric pressure, vacuum, temperature and humidity under the vacuum bag and communicate this data throughout cure to the Cloud via the TERVIA Hub. The system can be used to run automated leak rate tests on tools and vacuum bag setups. It also displays and records manufacturing parameters throughout cure. The system can also display cure progress vs. a programed time and temperature recipe and send SMS/email alarms when cure parameters are met or threshold temperature reached. It essentially acts as a hot bonder system without the heat application mechanism. However, at less than $1,000 USD for the hub, $99 USD for three vacuum probes and a monthly subscription of $39 USD for the advanced software license (there are also free and more expensive, customizable options), the total all-in cost is much more affordable.

Stay tuned for more blogs on new developments splashed at CAMX.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More