Colored carbon fiber

Options for adding color have been around for decades, but new products are hoping to up the ante and open new markets.

Two years ago, motorsports engineering company Prodrive (Banbury, UK) announced it had developed colored carbon fiber, after six months of research. Though it would not reveal any details, Prodrive showed off the images below, saying it could produce high-luster carbon fiber panels in almost any hue that are chip resistant, UV stable and highly consistent in both color and finish.

Motorauthority.com reported that Aston Martin, whose latest Vanquish model features a 100% carbon fiber body, would be interested. Indeed, the company’s unique personalization service, Q by Aston Martin, includes an option under SPORTING: “Cobalt Blue Carbon-Fibre is carried through to the facia, where the gradation runs from opaque to a clear weave at the base”; and another under MONTEREY 2013: “Jet Black Satin exterior is contrasted with gloss red tinted Carbon-Fibre trim.”

Motorsports firm Prodrive publicized its colored carbon fiber in April 2013 (left).

Q by Aston Martin features Cobalt Blue carbon fiber in its SPORTING option (center)

and red-tinted CF trim in its MONTEREY 2013 (right).

SOURCE: Motorauthority.com (left) and AstonMartin.com.

Though Prodrive has been quiet since 2013, another motorsports-based company, GPFone (Silverstone and London, UK) launched Hypetex in 2014, which it touts as the world’s first colored carbon fiber brand. Again, the technology evolved out of Formula 1 — this time after seven years of R&D — with details in short supply, but the company claims that Hypetex does not include filamentized glass fibers like some other products and thus maintains the essential high performance properties of carbon fiber.

|

|

|

Hypetex colored compound carbon fiber, reportedly developed by Formula 1 engineers, was showcased in designer Michael Sodeau’s Halo chair. SOURCE: GPFone.

Looking for a high-visibility way to introduce Hypetex, GPFone chose to work with London designer Michael Sodeau to produce the Halo chair, which features a thin wing-shaped seat on three legs and a disc-shaped back that gives a graphic silhouette. Hypetex reportedly enabled the structure to be thin and refined, yet robust. Winning the 2014 Red Dot Design Award for furniture, the Halo chair is reportedly available in six colors, with a limited production of six in each color.

As reported by Dezeen, Sodeau found that carbon fiber enabled him to generate shapes not possible with other materials and that Hypetex in particular offered a lot of design freedom: "It enables us to create a mono-material design, so aesthetically we can have a strong dynamic shape with one material over the whole object.”

Color via Other Fibers

Traditionally, colored carbon fabrics have achieved their rainbow hues via hybrid weaves with dyeable yarns such as glass, polyester and aramid. Vendors of these products are usually very straightforward about their products including caveats about the properties:

Please note that owing to the 50% coloured polyester yarn content of this fabric it does not have the same mechanical properties as 100% carbon fibre fabric, although it is still a high performance fabric.

— Easy Composites

This material is a blend of carbon fiber and colored copper wire.

— Composite Envisions

|

|

There are many carbon hybrid fabrics which use other fiber types to achieve color.

SOURCE: EasyComposites.co.uk (left), CompositeEnvisions.com.

Silver carbon fiber may actually be Texalium, a metal-coated glass fiber fabric from Hexcel (Stamford, CT). It is usually described exactly as this, though some less technical sources will call it silver carbon fiber while others explain that it is coated with aluminum approximately 200 angstroms in thickness. These latter sources will also describe post-treatment options which produce red, blue, yellow and other tints.

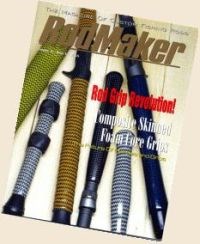

Soller Composites (Franklin, NH, US) has been selling its carbon and colored glass fiber hybrid fabrics for years, with adoptions in prosthetics, automotive aftermarket parts, fishing rods and other sporting goods.

|

|

Soller Composites sells a variety of colored glass/carbon fiber hybrid fabrics that are used in a variety of consumer goods. SOURCE: Soller Composites.

Aftermarket Artistry

When not using Texalium or colored Kevlar, the artists of the automotive aftermarket suggest imparting color to normal carbon parts through paint. Specifically, color-matched paint can be mixed into a clear binder like DBC500 from PPG (Pittsburgh, PA, US) and then topped with clear coats as normal. Some experts advise simply spraying with candy paint, which is a three-stage system using a metallic reflective basecoat, candy color coat, and clearcoat to create a deep, colored luster not attainable with typical automotive paints. It’s not clear if they are omitting the metallic basecoat.

|

|

Alternative to using colored glass or aramid fiber (left), auto aftermarket parts may achieve colored carbon via translucent or candy paint systems. SOURCE: DeftRacing.com and Honda-tech.com.

Revealing Patents

If indeed ProDrive and Hypetex are not using other fibers to achieve color, perhaps they are using technology developed decades ago but never widely adopted. Sumitomo Chemical Company's (Tokyo, Japan) patent EP0420655 A2, awarded in 1991, which describes a colored prepreg featuring a “widely variable high-grade hue with depth and luster” which cannot be abraded or worn off. This is achieved by using a polymer resin with 5 to 50 parts by weight — preferably 10 to 30 parts by weight per 100 parts by weight of the synthetic resin — of a flaky colorant having an average particle size of 70 to 300 µm and an average thickness of 0.1 to 10 µm. Particles sized less than 70 µm lack sufficient luster while those beyond 300 µm lack adequate dispersibility. The low and high bounds on colorant amount are set for the same reasons. "Hiding pigments" are also included in the technology, which may partially cover the color of the reinforcing fibers. Possible flaky colorants and hiding pigments are detailed.

Apple, too, has patented a method for “updating” carbon fiber’s look. Patent US7790637 B2, applied for in October 2007, simply uses an additional “scrim” layer that can mask the carbon fibers and impart a color other than black. Not aimed at transparent color that maintains the visual weave, but instead targeted to improve the cosmetic surface finish, Apple’s patent is interesting mainly in its motivation:

“. . .the resulting carbon fiber composite can have cosmetic imperfections that reduce the aesthetic appearance of the molded article formed therefrom. Further, carbon fiber composites, often being black, provide a narrow range of surface appearance to the molded article and therefore may give a “tired”, unexciting look.”

Even though projected use of carbon fiber continues to soar, maybe “the new black” could stand some color options.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More