The case for recycled carbon fiber is a complicated one. The industry is built on the hope of solving problems — namely, the desire to keep carbon fiber waste out of landfills and to fill a potential gap between carbon fiber supply and demand. It is commonly estimated that around 30% of produced carbon fiber ends up as waste. Meanwhile, as valuable material ends up in landfills, most analysts agree that annual demand for the material could surpass current annual production capacity within the next few years. The average estimated global carbon fiber demand is around 65,000-85,000 metric tonnes per year, with a global nameplate capacity (which is more than actual capacity) of around 150,000 metric tonnes, according to estimates presented by Brett Schneider, president, global fibers, Hexcel (Stamford, Conn., U.S.) and Dan Pichler, managing director of CarbConsult GmbH (Hofheim am Taunus, Germany) at the December 2018 Carbon Fiber conference. As reported by CW contributor Amanda Jacob in March, some analysts estimate that carbon fiber demand could exceed supply by about 24,000 metric tonnes by 2022. (see “Building confidence in recycled carbon fiber.”)

And while commercial suppliers of recycled carbon fiber (rCF) point to reclaimed and repurposed material as a potential solution to this supply and demand gap, the rCF industry has its own challenges. While the technology to recycle carbon fiber composites has existed for several years and is capable of yielding a product with mechanical properties very near that of virgin material, the composites recycling industry is relatively young and is still in the early stages of developing markets for the materials it produces from recyclate. As confidence in the quality of fiber being produced by recyclers increases, questions about cost and availability have come to the forefront. Perhaps the largest challenge for the industry is the concern over supply chain security.

“The technologies are actually there, and they’ve existed for quite a while, but the supply chain just hasn’t been vetted,” says Andrew Maxey, CEO of Vartega (Golden, Colo., U.S.). “Without the right pieces coming together you can have the best technology in the world, but you’re not going to have material to recycle and you’re not going to have any products to put it in.”

Commercial suppliers often look to the aerospace industry as a source of production scrap and end-of-life material to be used as recyclate, yet while the amount of waste created by the aerospace industry is large in terms of what is going to the landfill, many OEMs and fabricators have been reluctant to rely on it as a steady supply source for a high-volume product line.

On the other hand, some progress is being made. In December 2018, Boeing announced it will supply carbon fiber recycling specialist ELG Carbon Fibre Ltd. (Coseley, U.K.) with cured and uncured carbon fiber waste to be recycled for use in secondary products for other composites manufacturing applications. The agreement is the first formal material supply relationship between a carbon fiber recycler and a major aircraft OEM and seems to be a good portent for the industry.

It’s not just about environmental concerns

The argument for using rCF goes beyond sustainability. Reduced cost is also a benefit. For example, ELG Carbon Fibre’s rCF costs around 40% less than industrial grade virgin carbon fiber. Other commercial suppliers claim their material is anywhere from 20% to 40% less expensive than virgin carbon fiber. Plus, for many applications there is a need for discontinuous fiber formats — which suggests an opportunity where rCF might offer a more sustainable and economical alternative to virgin material.

“Anywhere the industry is using discontinuous or chopped carbon fiber, recycled [fiber] should be the first consideration,” says Maxey. “We spend all this money to make virgin carbon fiber in a continuous format … why do we then take that and go chop it up to put into thermoplastic? If we already have a discontinuous format in those scraps, that’s the best material to use, in my mind, for those molding compounds where you’re just going to chop it up anyway.”

Plus, the quality of rCF being produced has been shown, in some cases, to be on par with virgin fiber. ELG Carbon Fibre, which reclaims carbon fibers using pyrolysis, says its fiber typically retains at least 90% of its tensile strength with no change in modulus. Vartega uses a chemical recycling process and claims that its fiber exhibits the same mechanical properties as virgin carbon fiber. Shocker Composites (Wichita, Kan., U.S.) uses an inline solvolysis process to reclaim the fiber and claims high quality with no apparent damage to fibers.

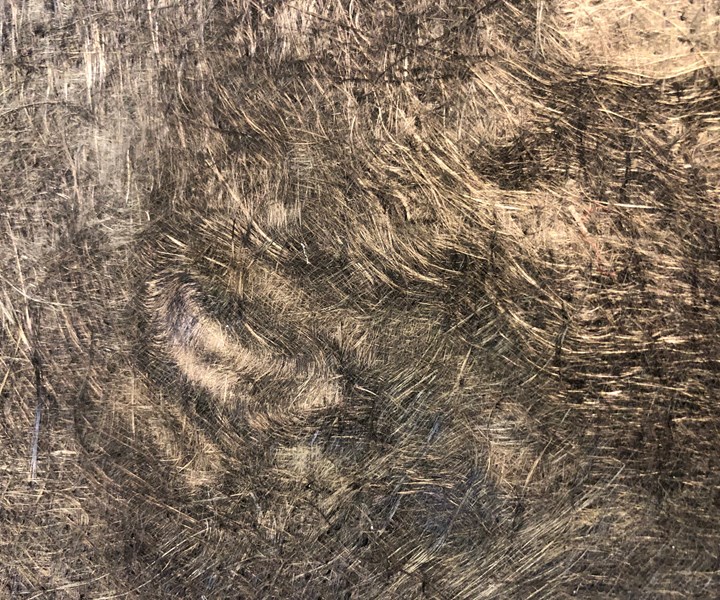

Recycled carbon fiber nonwoven mat from ELG Carbon Fibre.

CW photo | Scott Francis

According to Vamsidhar Patolla, Wichita State University Ph.D. student and founder of Shocker Composites, the challenge is all about getting the cost down to a level comparable to that of other materials such as aluminum. “Processability needs to match the high-volume production scale,” he says. Shocker Composites’ process offers this advantage because it is an inline process, not a batch process. (Learn more in the article “Sustainable, inline recycling of carbon fiber.”)

Given recent improvements over the past several years in rCF processing and fiber quality, commercial suppliers have begun to shift their focus from the downcycling of rCF into lower-performance products and more toward finding appropriate applications that benefit from the material’s properties.

“We’ll never displace virgin fiber completely, especially in aerospace where there are high strength and stiffness requirements, but people are coming around to the idea that recycled fiber isn’t just recycled fiber with weak potentials,” says Benjamin Andrews, field technical services engineer with ELG Carbon Fibre. “It has its own benefits that are superior to virgin fibers in some applications. Drapability and surface finish are both better than that of virgin fiber … this isn’t just a reusable material; this is a material that has its own benefits.”

What’s up with automotive?

When it comes to markets, the automotive industry seems like it should hold the most potential for using rCF. The material’s ability to combine lightweighting with good surface finish makes it a natural fit for body panels, not to mention various interior components. Commercial suppliers of rCF have long looked to the industry with bated breath, hoping for widespread adoption, but a tipping point has yet to arrive. Process time and cost continue to be stumbling blocks for the industry.

Mark Mauhar, CEO of Carbon Conversions (Lake City, S.C., U.S.), argues that these concerns are a bit of an excuse given the progress that has been made, and he feels that the main barrier to adoption into any market is actually risk aversion.

“Nobody wants to be first to adopt a new material ecosystem,” he says. He also stresses that large-scale adoption of rCF by the automotive industry is not necessarily even desirable, pointing out that usage adoption by a dozen major automotive platforms could quickly consume the global supply of rCF. He says the approach should be to target niche programs, which will, in turn, make the supply chain more robust from a business perspective.

Automotive door panel made from prepreg made from Carbon Conversions’ re-Evo MCF.

CW photo | Scott Francis

“It pays to be smart about where you put it in automotive,” he says. “Picking specific parts on specific models of cars that make sense.”

Mauhar is hopeful that automotive will be the first major market space to consume a decent fraction of the available recycled carbon fiber. “In the next 24 months we’ll start seeing some movement there,” he predicts.

Composites, in general, are working their way into the automotive industry incrementally in the form of parts such as battery boxes, pressure vessels, leaf springs and even lift gate systems. It would make sense for rCF to follow the same trajectory.

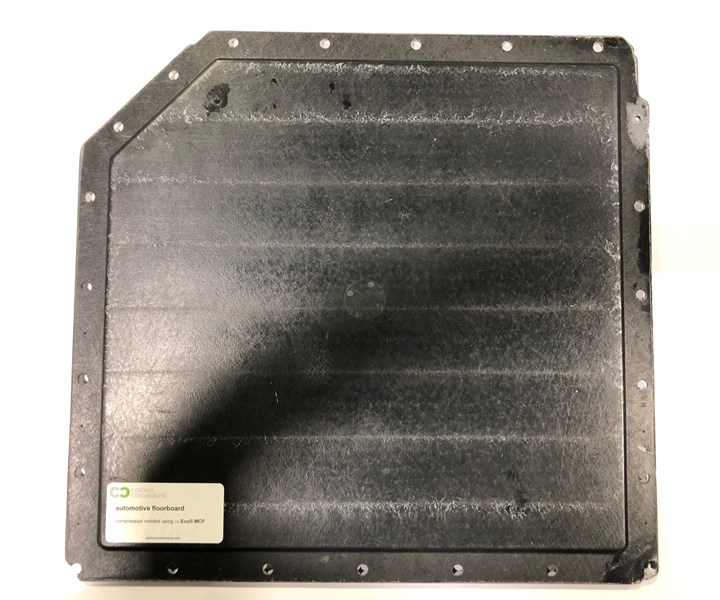

This compression molded automotive floorboard uses Carbon Conversions’ re-Evo MCF nonwoven mat.

CW photo | Scott Francis

One interesting example of such a niche approach is ProDrive Composites (Milton Keynes, U.K.), manufacturer of advanced lightweight composites for applications ranging from automotive and motorsport to aerospace and defense. The company has been collaborating with the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Sheffield, U.K.) and ELG Carbon Fibre on its P2T (Primary To Tertiary) process, a new process that uses a reactive thermoplastic resin for manufacturing recyclable composite components. A plastic monomer is reacted with a catalyst in the presence of recycled fibers to produce a cured laminate, out of the autoclave.

Example of a tertiary part produced using ProDrive’s P2T process.

CW photo | Scott Francis

“[We] have demonstrated that recyclable composite panels can be produced at a rate and cost to suit many industries,” says John McQuilliam, chief engineer at ProDrive Composites.

The company says P2T allows a composite material to be used three or more times. At the primary part’s end-of-life, the fibers and potentially the resin can be recycled, supplying raw material for a thermoplastic secondary part, such as a body panel. When that part reaches its end of life, it can be chopped and remolded into new parts. (Learn more in the article “P2T process positioned for recycling.”)

Meanwhile, Vartega is leading an Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, Tenn., U.S.) project focused on the automotive industry. The two-year technical collaboration is designed to address the challenges of creating consistent recycled carbon fiber-reinforced thermoplastics for use in vehicle lightweighting applications. Maxey says the project is making progress toward a robust dataset that offers a full characterization of materials, from the fiber interface to finished part properties.

Of course, when considering the auto industry, the best bet might be on related emerging technologies. Electric vehicles, autonomous vehicles and connectivity aspects in cars bring new parts and applications opportunities where composites will likely play a large role.

Maxey offers his assessment of where the auto industry is heading: “There’s a lot that’s gone on in the past couple of years in the auto industry, where the focus will shift from fuel economy to other priorities depending on what the regulations are and what the [presidential] administration is saying,” he says. “[We’re] not seeing any major pullback on lightweighting, but maybe the motivation for it evolves. I think what you’ll see in the industry is the focus on lightweighting for mobility applications.”

Can aerospace close the loop?

The aerospace industry generates the most carbon fiber waste, and commercial rCF suppliers often look to the aerospace industry as a source for recyclate. Excess material, typically uncured thermoset composite prepreg, is collected and the resin is removed via heat (pyrolysis) or a chemical solvent (solvolysis) to yield fiber that is milled, chopped or pelletized.

As the industry moves toward increased use of thermoplastic composites (TPCs), that material presents a new set of recycling opportunities. Because thermoplastic polymers can be remelted and reshaped, the aerospace industry has more opportunity to reabsorb some of its own scrap into secondary applications, potentially reusing both fiber and matrix. Thomas de Bruijn, researcher at the Thermoplastic Composites Application Center (TPAC, Enschede, Netherlands) — a thermoplastic composites R&D center working alongside the Thermoplastic Research Center (TPRC, Enschede, the Netherlands) at an applied research level — points to efforts in the industry being made to recycle the material internally.

“From a feasibility point of view, for thermoplastic composites, an in-house approach makes much more sense,” he says.

According to de Bruijn, aircraft OEMs are more likely to recycle internally than turn to a commercial supplier of rCF. The main reason for this is traceability. Matching polymer types to a given application becomes much more difficult when the supply is moved out-of-house.

Johan Meuzelaar, engineering stress specialist at GKN Fokker (Hoogeveen, Netherlands), thinks the answer is to try to find as many applications as you can within your own production environment. “If I look at the type of thermoplastic components we make from virgin material, there’s a lot of parts in them which we could make recycled,” he says. “[We could] certainly use up a significant amount of waste that we’re generating.”

“We already have the facilities,” adds Guillaume Vincent, thermoplastic composites engineer at the TPRC. He explains that recycling internally fits within the normal process chains and that the majority of the equipment is already in place, making it the most affordable avenue. “[It] fits into activities we have in a normal production environment.”

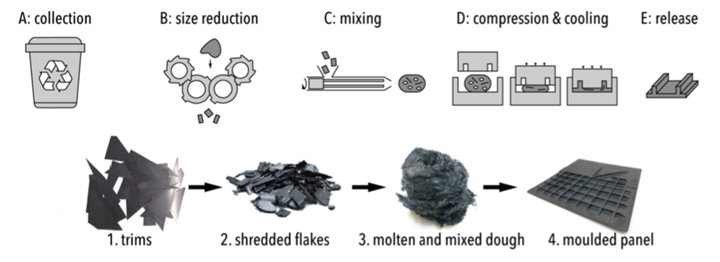

TPC-Cycle recycling route

TPC-Cycle recycling route

Source | TPRC, TPAC

De Bruijn, Vincent and Meuzelaar are involved in the TPC-Cycle project, operated by TPAC and the TPRC. The project is aimed at the re-use of production scrap from thermoplastic composites processing for aerospace and high-volume applications. The objective is to retain the high mechanical properties of thermoplastic composites and to reduce the overall environmental impact at an affordable cost. The TPC-Cycle boasts short cycle times and is said to enable the production of complex shapes.

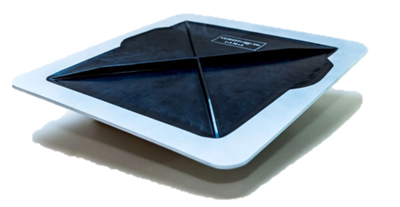

Demonstrator access panel for rotorcraft developed using the TPC-Cycle process.

Source | TPRC, TPAC, GKN Fokker

Several industrial partners, including GKN Fokker, Toray Advanced Composites (Morgan Hill, Cali., U.S.; Nijverdal, Netherlands), Cato Composite Innovations (Rheden, Netherlands), Dutch Thermoplastic Components (Almere, Netherlands) and Nido RecyclingTechniek (Nijverdal, Netherlands), are involved in the TPC-Cycle project, representing different segments in the value chain from material, manufacturing, design and application.

According to de Bruijn, the TPC-Cycle project is now looking into completing cost analyses and life cycle analyses to prove that the process is economically beneficial.

In addition, programs such as the Clean Sky 2 Joint Undertaking (which is funded by the EU’s Horizon 2020 programme) are encouraging R&D that focuses on closing the loop for aerospace scrap. OEMs are looking to the potential of using recycled factory waste for interior parts, access panels, small components and even airframe clips and system brackets.

Dr. Bas Veldman, GKN Fokker program manager for the lower half of a thermoplastic Multifunctional Fuselage Demonstrator, is fostering this concept by launching a call for proposals under the Clean Sky 2 program on clips and brackets. An important element in the development of the demonstrator is to reduce environmental impact through the use of factory waste for such products as frame clips and brackets. The demonstrator also aims to replace fasteners with welding, thereby saving materials, energy and cost while contributing to lightweighting.

According to Meuzelaar, GKN Fokker is investigating how recycling technology might be part of the company’s fuselage of tomorrow concept. He says the concept will potentially use a lot of thermoplastic composites, which in turn could generate a lot of waste that could be used for recycled bracketry, fittings and nonstructural parts.

“The reason for looking at a thermoplastic fuselage is cost, and we think this is a cost economic production method, which also incorporates recycling,” he says.

Meuzelaar says the goal at a high level is to make more affordable and more sustainable products in aerospace. While strides are being made toward series production in thermoplastics, this will also yield waste (as is unfortunately the case for composites in general). But he believes that waste can be commercially viable and says that low-shear mixing/compression molding of recycled carbon fiber TPCs offers design freedom not afforded by traditional laminating with continuous fibers. “You get a lot of additional options to make very interesting non-structural parts like panels, small fairings or system brackets which usually in aerospace tend to be overdesigned in terms of materials used, alloys used, [and] the production systems used,” he explains.

He believes the opportunity lies mainly in nonstructural parts of medium size and medium complexity, which are still a significant part of the total cost of the larger components.

“We won’t make wings out of recycled thermoplasticin the near future,” says Meuzelaar. “But inside the wing, there are parts we can make that make economic sense.”

All of that said, it’s a bit far out to predict the impact thermoplastic composites will have on the recycling industry.

“Percentage of waste will decrease probably due to new production methods like tape placement or tailored blanks, which probably produce less waste than the current typical nesting and stamp forming processes that we see,” de Bruijn says “But in general I think there will be more thermoplastic waste in the coming years and decades.”

And while this interest in recycling in-house is on the rise, there will always be some waste that is not usable and that fabricators will be unwilling or unable to recycle in-house. In such cases, those materials might be reclaimed by a material supplier. Time will tell what the increased use of thermoplastic composites might mean for the supply chain. (Learn more about the TPC-Cycle project and the Clean Sky 2 initiative in “Recycled thermoplastic composites for production.”)

Additive manufacturing

Additive manufacturing is another area that holds potential for rCF. For example, Shocker Composites has compounded its recycled carbon fiber into 20-40% reinforced ABS filament and demonstrated its successful use with Cincinnati Inc.’s (Harrison, Ohio, U.S.) Big Area Additive Manufacturing (BAAM) 3D printing process.

In addition, Vartega says it is leveraging its carbon fiber recycling technology and material development expertise to advance polymer feedstocks for powder bed fusion additive manufacturing. The company was recently awarded a National Science Foundation (NSF, Alexandria, Va., U.S.) Small Business Innovation Research (SBIR) grant to conduct research and development (R&D) in the area.

Vartega claims to also be developing a process that will allow thermoplastic powders to be reinforced with carbon fiber while ensuring the materials produce functional parts in infrared additive systems. This advancement reportedly will enable digital manufacturers to realize the full potential of new powder-based hardware platforms to produce parts that perform similarly to injection molded materials at medium-volume production rates.

“By offering carbon fiber-reinforced polymer powders, manufacturers in sectors like UAV [unmanned aerial vehicles] and medical prosthetics will realize the benefits of fast, complex and customized 3D printing, while ensuring that their material selection will exhibit the structural integrity required for their product,” says Alice Havill, chief operating officer at Vartega.

Other applications

Meanwhile, other markets and applications in which recycled carbon fiber can play a role continue to emerge.

This construction grade cross-laminated timber (CLT) combines thermally modified lumber with recycled carbon fiber from the Composite Recycling Technology Center.

Source | The Composite Recycling Technology Center

The Composite Recycling Technology Center (CRTC, Port Angels, Wash., U.S.) has been exploring use of recycled carbon fiber in a variety of products, from park benches to high-performance sporting goods to composite tubing. The company works with reclaimed uncured prepreg material from Toray Composite Materials America (Tacoma, Wash., U.S.) as well as rCF from ELG Carbon Fibre.

Dave Walter, CEO of the CRTC, points to the construction industry as an area of potential growth. The company recently developed a construction grade cross-laminated timber (CLT) under a patent-pending process that combines thermally modified lumber with recycled carbon fiber. The thermal modification process cooks off the sugars and lignin, providing rot and termite resistance, and then carbon fiber strips are integrated for strength.

The CRTC also uses recycled carbon fiber to create panels bonded with wood veneer. These panels showcase the beauty of wood with a strong, light and flexible substrate for various interior and exterior applications, as shown in the picture below from a 2019 installation at the Benaroya Hall in Seattle.

Octave 9 Raisbeck Music Center – Benaroya Hall (Seattle, Wash., U.S.)

Photo | The Composite Recycling Technology Center

A mind change for the industry?

Big changes often happen incrementally, and the relatively young recycled carbon fiber industry continues to slowly push forward. While downcycling of rCF continues, perceptions about the material are beginning to change. Quality of fiber has been proven and processes continue to evolve. Awareness of the necessity to recycle carbon fiber is high and more players are getting involved.

“The ELG and Boeing announcement was a really big deal; it helps everyone move the ball forward [and] to accelerate the supply chain connections,” says Maxey.

“We’re here to enable and connect the dots,” he adds, summing up the industry. “We have this enabling technology that sits in the middle of the supply chain, but its really about connecting that stranded asset in the waste stream to an unmet demand downstream.”

The biggest change, according to Mark Mauhar of Carbon Conversions, is that suppliers now want to be part of the solution. “Prior to two years ago we’d get multiple calls a week from suppliers about getting rid of scrap, but no interest in using the material,” he says. “Now, people are starting to walk the walk. Only recently, we are finally starting to see potential customers of reclaimed carbon fiber spend significant resources in cutting molding tools, building prototypes and mock-ups, solving process issues — all activities that are well down the line in terms of commercial adoption.”

Perhaps what it really boils down to is patience. Detlef Drafz, CEO at ELG Carbon Fibre, points out that it’s helpful to examine the recycling history for other legacy materials.

“For over 50 years, ELG has recycled raw materials for the stainless steel industry. With metal, it’s accepted that you use the scrap even in vacuum furnaces for turbine blades … it’s accepted that recycled metal is a raw material, which properly processed can just be used. That wasn’t common in the aerospace application 25 years ago; however, we established a supply chain in order to give the guarantees that the material performs. We do the same here,” he says.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More