Case History: Scout’s 420 LXF made possible with Vectorply’s Road to Optimization

With a list of must-meet goals in hand, Scout Boats, Inc. turned to Vectorply to assist with laminate design and technical recommendations as they tackled their first epoxy-infused boat hull.

Share

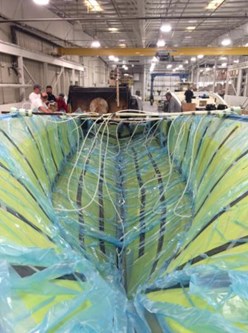

Scout’s epoxy-infused boat hull

In an industry as diverse as the U.S. marine market, Vectorply Corporation understands that each boat builder has unique goals they strive to achieve with individual projects or models. With a list of must-meet goals in hand, Scout Boats, Inc. turned to Vectorply to assist with laminate design and technical recommendations as they tackled their first epoxy-infused boat hull.

“Scout’s willingness to be open-minded and venture into new realms of production to achieve the cosmetics and see the added bonuses of epoxy was a worthwhile investment that their customers will value,” said Vectorply Southeastern Region Sales Manager Jordan Haar. “This reinforces Scout’s commitment not only to the industry, but also to their customers by producing a top-quality product.”

To achieve the goals that Scout had for the new 42’ boat, Vectorply put its Road to Optimization (R2O) – a tool for evaluating a company’s laminate and production process from the time material is delivered until the customer’s product is complete – to the test.

A team consisting of Vectorply, Composites One, Magnum Venus Products (MVP), and 3A Composites was on-hand to hear the objectives that Scout Boats wanted to achieve with the 420 LXF. “We chose this team because they were focused on our needs and their attention to detail was second to none,” said Scout Boats Director of Manufacturing William Ferguson.

Weight reduction and high cosmetic appeal were two of Scout’s biggest goals for the new model. The cosmetic appeal of the new boat would need to be at least equal that of a traditional open molded hull, but the ambition was to be even more aesthetically pleasing. A boat as large as the 420 LXF would also need to be light enough to maintain top-of-the-line performance on the water.

With these goals in mind, Vectorply’s proprietary laminate building software program, VectorLam, was employed to create the optimal laminate. VectorLam helped the design team reach a lower weight by reducing or eliminating costly or heavy products such as resin and putty. That enabled them to utilize higher quality laminates, which reduced potential voids and created a better mechanical bond, resulting in peace of mind for the boat’s new owner.

The hull infusion confirmed that Vectorply’s R2O solution achieved drastic savings in labor time and weight. Building the hull reduced labor by 20 percent and finishing time dropped 50-60 percent from open molded hulls, according to Ferguson. The already lightweight hull, which was previously core-bonded, also achieved a 15 percent weight savings. As for cosmetics, the Vectorply solution performed better than expected to create one of the sleekest boats on the market.

Scout’s 420 LXF

An added benefit of the Vectorply solution was a cleaner production facility with less waste and better working conditions for employees. “Many of Scout’s employees want to be involved on the closed mold team,” said Haar. “I am excited to see employees more engaged and learning new skill sets to produce a better product.” Ferguson also was pleased with the somewhat unexpected cleaner and more engaged work environment.

Scout has big plans for utilizing closed molding infusion. In the LXF series, the 380 and 350 models are the next hulls planned to be epoxy-infused. Ferguson also said that stringers and consoles are scheduled to be produced through closed molding.

As the new Scout 420 LXF proved, Vectorply’s Road to Optimization can turn ideas into real-world processes and results. Available free to any customer, it demonstrates Vectorply’s commitment to helping businesses create the best, most innovative products on the market.

Read Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More