Airborne introduces automated pick-and-weld preforming system

The robust, flexible and versatile three-step system handles a range of dry fiber and thermoplastic composite material forms for high output, improved efficiency and reduced waste.

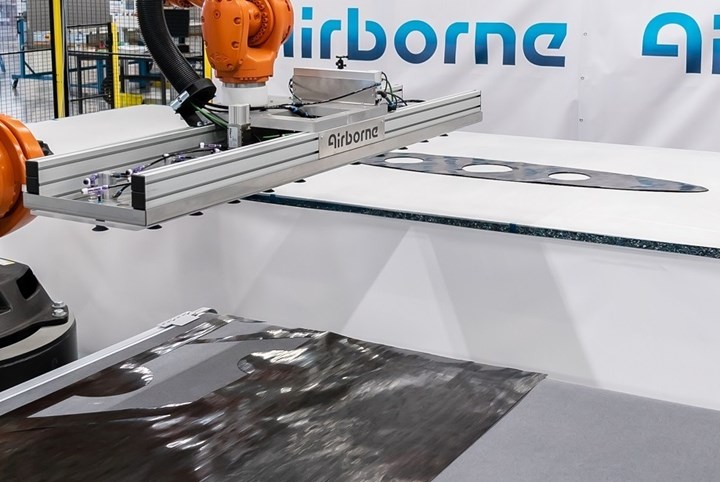

Photo Credit: Airborne

Airborne (The Hague, Netherlands), an automated solutions provider for composites manufacturing, has developed a fully automated and flexible manufacturing process, the Automated Preforming system, for creating composite preforms in dry fiber and thermoplastic composites. According to the company, the system provides the freedom to create any preform shape and size (making free-form edges and 100% net-shape), as well as thickness variation; it can also make cut-outs in the middle of the ply. Overall, the process is said to retain high output, improve efficiency and remove high cost.

The solution is based on three steps, Airborne says: cutting of the material on a conveyor cutter or tape feeder; picking of the material by the robot; and placing and spot-welding the plies to create a stabilized preform. The system can work with existing, wide material rolls for cost optimization. Further, since it uses existing processes for cutting and welding, the system does not require new designs or qualifications. Depending on the need, Airborne says, different variants can be supplied, optimized for productivity, accuracy or flexibility. The preforming system is put into action in the video below.

Typically, Airborne notes, the process of creating a preform is costly. Many composite forming processes, such as press consolidation, press forming, vacuum forming or diaphragm forming, are based on the use of tailored 2D preforms or blanks. Although the forming processes are usually automated, the blanks or preforms going into these processes are often produced manually — a repetitive process, requiring both skill and concentration from the operators. Further, with higher production rates, it becomes increasingly difficult for operators to keep up with production while maintaining quality. And if automation of the process is considered, in many cases, the engineering and programming time is prohibitive, especially in factories with a wide mix of products.

Airborne says its new system meets these challenges. Automated programming allows for short start-up times, with no programming needed. The design file can also be loaded directly into the machine and the preform can be made without intervention. Airborne says the system handles dry fiber and thermoplastic composite materials in many different forms (UD, fabric, core materials, surface films, adhesive films, etc.). Functionalities can be added, as needed (quality control, preform offloading, additional material feeds, higher volume material feeds, etc.).

“The basic principle of the system is very simple: ‘pick and weld’. This is a pick-and-place action by the robot during which we spot-weld the plies,” says Marcus Kremers, CTO, Airborne. “We like this conceptual simplicity since it makes the process very robust, flexible and versatile. Of course, the devil is in the detail to make it work consistently with the right quality. In many cases, customers handle lots of different materials and product designs. Their ideal situation is to have a single automation technology and that’s what we can provide them.”

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.