Altair's 9th Enlighten Award winners feature vehicle lightweighting, sustainability

Annual award honors advancements in reducing the carbon footprint, mitigating water and energy consumption, promoting material reuse and recycling and applying composites for lightweighting.

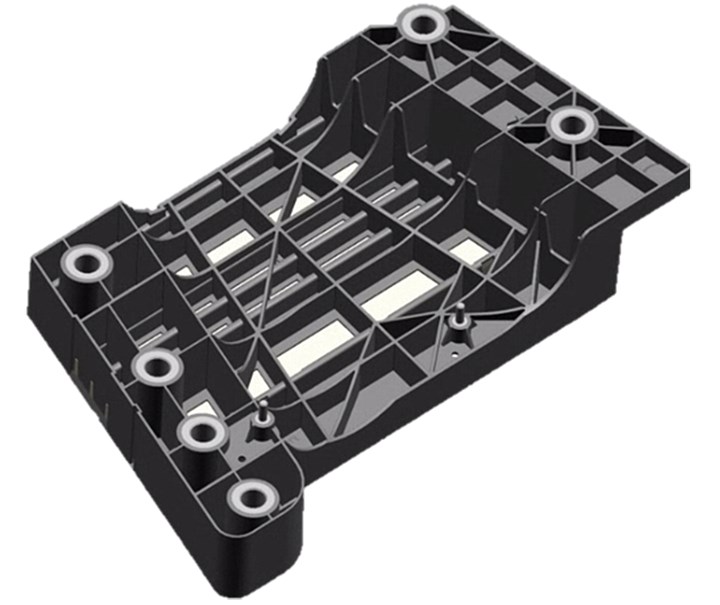

Stellantis Jeep Grand Cherokee composite tunnel reinforcement. Photo Credit: Altair

Altair Engineering (Troy, Mich., U.S.) a global technology company converging simulation, high-performance computing (HPC) and AI, has announced the winners of the 9th annual Altair Enlighten Award (see “Composites feature in Altair’s 8th Annual Enlighten Awards” for 2020 winners). Presented in partnership with the Center for Automotive Research (CAR, Ann Arbor, Mich., U.S.), the award recognizes the automotive industry’s sustainable engineering initiatives, focusing on lightweighting and the use of innovative materials, technologies, and techniques to cut CO2 emissions.

“The 2021 Enlighten Award once again shines a light on the inspiring work of automotive engineers worldwide. Now more than ever, sustainability and emissions reduction are critical challenges not just for the automotive sector, but society as a whole,” says James R. Scapa, founder, chairman and CEO, Altair. “By enabling unprecedented convergence of simulation, data analytics and HPC, Altair is proud to continue to celebrate and power lightweighting initiatives around the globe as automotive organizations transform pioneering ideas into production-ready solutions more quickly and efficiently.”

Presented in six categories, the full list of winning projects, runners-up and honorable mentions for 2021 include:

- Sustainable Product – Vehicle winner: Ford Motor Co. (Dearborn, Mich., U.S.) for its 2021 Ford Mustang Mach-E. The all-electric vehicle is said to emit zero CO2 while driving, and its sustainable credentials are further supported by a 100% vegan interior that eliminates the use of animal products.

- Sustainable Product – Component winner: Magna International (Aurora, Canada) 2019 RAM 1500 Active Air Deflector and Grille Shutters: Using lightweight, cost-effective and 78% recyclable plastics, the RAM 1500 Active Air Deflector and Grille Shutters reportedly reduce drag by 9% for better fuel economy. Aero products on the RAM 1500 have reduced CO2 emissions by 641.9 thousand metric tons since January of 2015.

- Runner-up: SAIC GM Wuling Automobile Co. Ltd. (Liuzhou, China) for the Wuling Victory: To help achieve both lightweighting and safety goals, the Victory design features increased use of high strength steel, ultra-strength steel and hot-forming process on body in white (BIW). The whole vehicle weight is reduced by 61.5 kilograms, enabling an improvement in fuel consumption of 0.2 liters per kilometer.

- Sustainable Process winner: Faurecia (Nanterre, France), NAFILean Stiff: NAFILean Stiff is a polypropylene compound that uses 20% bio-sourced contents and is 100% recyclable. NAFILean Stiff is the latest innovation of the NAFILean family. Implemented since 2013 in 17 production vehicles since 2013, the NAFILean Family stands to benefit a fleet of 14 million vehicles. Delivering a 21% reduction in weight, it has offered a savings of 100,000 tons in CO2 emissions (assuming a 10-year lifetime at 15,000 kilometers per year for 14 million vehicles), and an additional 811 million kilometers traveled with the same quantity of fuel.

- Runner up: Henkel (Rocky Hill, Conn., U.S.), PALLUMINA Metal Pretreatment Process: Used in the production of the 2021 Toyota Tacoma and Tundra, PALLUMINA is said to provide significant sustainability advantages compared to conventional processes, including eliminating the use of heavy metal phosphates, reducing sludge generation up to 90%, and decreasing the use of water up to 50%.

- Lightweighting Enabling Technology winner: ArcelorMittal (Luxembourg, U.K.), FORTIFORM 980GI Next-Generation Steel: Combining high ductility for complex shapes with higher levels of strength for improved safety, FORTIFORM 980GI offers potential weight savings of up to 20%.

- Runner-up: JAC Group (Tokyo, Japan), JAC SOL A5, Fastback Sports Car: JAC Group established an integrated, simulation-driven design process for body structural design. Applying a multi-disciplinary approach that also embraced safety, noise, vibration, harshness (NVH) and durability, a reduction in whole vehicle weight of 106.3 kilograms was achieved.

- Honorable Mention: U.S. Steel (Pittsburgh, Pa., U.S.) Body-in-White (BIW) Assembly using U.S. Steel 980 XG3 Gen3 AHSS: Combining strength and formability without compromising weldability, U.S. Steel 980 XG3 is said to realize weight savings of approximately 10% with potential improvement in safety performance compared to previous program BIW.

- Module Lightweighting winner: Stellantis (Amsterdam, Netherlands), 2021 Jeep Grand Cherokee Composite Tunnel Reinforcement (partners: Stellantis, BASF, L&L Products): The industry-first Jeep Grand Cherokee composite tunnel reinforcement is designed to carry a critical load path and achieves a 40% weight savings on the component itself, and a further 20% on the subsystem. The total weight savings per vehicle is 2.08 kilograms and is combined with lower costs for both the component and initial tooling. L&L Product’s Continuous Composite Systems (CCS) pultrusion technology, along with BASF’s Elastocoat 74850 polyurethane pultrusion system were key factors in the tunnel reinforcement’s development.

- Runner-up: Rassini Suspensiones (Piedras Negras, Mexico), Lightweight, Multi-Material Leaf Spring: The lightweight, multi-material “hybrid” leaf spring uses glass fiber-reinforced polymer (GFRP) composite materials and high-pressure resin transfer molding (HP-RTM) manufacturing technology which enables a 30% percent weight savings over the previous product generation. Because the design is widely applicable to light-duty trucks, and medium and heavy commercial vehicles, the potential total annual market is estimated at nine million leaf springs.

Rassini Suspensiones lightweight, multi-material leaf spring. Photo Credit: Altair

- Future of Lightweighting winner: American Axle & Manufacturing (AAM, Detroit, Mich., U.S.), Electric Drive Unit (eDU): AAM’s eDU saves more than 25% in mass compared to similar units on the market. Integrating the electric machine, gearbox and inverter in a compact package, it also demonstrates a higher power-to-weight ratio than competitor products.

- Runner-up: Shiloh Industries (Valley City, Ohio, U.S.), Aluminum Curvilinear Laser-Welded Blank: Representing what is said to be the industry’s first aluminum curvilinear laser-welded blank, this one-part, one-stamping solution eliminates four original parts. In a typical liftgate, for example, this results in a 16% weight reduction. At 5.3 kilograms per vehicle, that would mean a total savings of three million kilograms of aluminum per annum, based on a 300,000-vehicle production volume. In addition, potential cost savings of $18 per vehicle are realized.

- Honorable Mention: Dura Automotive Systems (Auburn Hills, Mich., U.S.), Dura Modular EV Battery Tray: A modular and scalable design that can be tailored to multiple platforms and vehicles of all types and sizes, the Dura modular EV battery tray delivers a 10% weight savings over the surrogate design and a reduction in CO2 emissions of 3.8 tons over the program life.

“Our mission is to deliver world-class research and analysis on key issues facing the automotive industry and their impact on society and sustainability. Lightweighting is central to the quest for greater fuel economy and electrification, which in turn is vital to the future of the whole sector,” says Carla Bailo, president and CEO, CAR. “We are delighted to collaborate with Altair in celebrating another stellar array of truly innovative projects.”

Winners will be formally announced in an awards ceremony at 8 a.m. ET on August 4, 2021. To attend MBS and view the awards ceremony, visit https://www.cargroup.org/mbs/. Media partners for the 2021 Altair Enlighten Award include SAE International, Automotive Engineering and Automobil Industrie. For more information about the Enlighten Award, visit https://www.altair.com/enlighten-award/.

Related Content

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More