Airbus ASCEND program to explore liquid hydrogen and superconductivity for zero-emission aircraft

Cryogenic hydrogen as cold source for lightweight, low-electrical loss powertrain, with composite materials as possible insulation.

Share

Photo credit: Airbus

Airbus reports that it has created the ASCEND program to demonstrate electric- or hybrid-electric propulsion, combining liquid hydrogen and superconductive technologies. A ground demonstrator will be built by Airbus subsidiary UpNext (Ottobrunn, Germany) targeting a minimum of 50% reduction in powertrain weight and electrical losses while increasing efficiency by 5-6% compared to conventional technologies. Composite materials reportedly will be considered for cryogenic insulation.

Airbus notes that one of the major challenges of scaling up electric propulsion to larger aircraft is the power-to-weight ratio. Today’s electrical systems simply do not meet the necessary power requirements without adding excess weight to the aircraft. But superconducting technologies are emerging as a promising solution to this problem, notably by increasing power density in the propulsion chain while significantly reducing the mass of the distribution system.

Superconductive materials conduct very high electric currents with practically zero resistance — and thus, very low energy losses — when maintained at very low temperatures. Such materials are already being used in magnetic resonance imaging (MRI) and electrical power transmission cables, as well as some electric motors and generators. However, superconductivity has not yet been fully explored in aerospace applications.

Notably, the three ZEROe (zero-emission) aircraft that Airbus revealed in Septerber 2020 will use liquid hydrogen (LH2). Like superconductive materials, LH2 must also be maintained at cryogenic temperatures. Instead of this being an obstacle, Airbus aims to use LH2 as a cold source to exploit the benefits of superconductivity.

ASCEND

Airbus’s Advanced Superconducting and Cryogenic Experimental powertraiN Demonstrator” (ASCEND) program is a 3-year effort to explore the impact of superconducting materials and cryogenic temperatures on the performance of an aircraft’s electrical propulsion systems.

Airbus will use ASCEND to explore the feasibility of these promising technologies to optimize propulsion architecture for zero-emission flight. Results are expected to show the potential for component weight and electrical losses to be cut by at least 50% as the volume and complexity of systems installation is reduced, compared to conventional technologies. The system should also keep voltage to less than 500 volts, compared to current systems, making it easier to manage problems such as arcing.

“The ASCEND program looks like a follow-on to the aborted E-Fan X, which had begun studying hybrid-electric propulsion,” explains Aviation Week editor Thierry Dubois in his April 9 article, “Airbus’ hydrogen drive will materialize in demonstrators.” Led by Airbus and Rolls-Royce, he notes, it involved a 3,000-volt electric system, but faced a key challenge to handle the hundreds of kilowatts of waste heat it generated.

“Superconductivity solves the heat management issue,” says Dubois, “thanks to the absence of any resistance and the related Joule effect.” He notes the expectation is that the technology will increase efficiency by 5-6% compared to conventional technologies, according to Ludovic Ybanez, head of the ASCEND demonstrator program.

Airbus will design and build the demonstrator over the next three years at its E-Aircraft System House, under the umbrella of its UpNext subsidiary (Ottobrunn, Germany), created to give future technologies a development fast track by building demonstrators at speed and scale, evaluating, maturing and validating new products and services that encompass radical technological breakthroughs.

ASCEND will test and evaluate solutions that could be adapted to turboprop, turbofan and hybrid propeller engines by the end of 2023. It will support Airbus’ decision-making process for the type of propulsion system architecture required for future aircraft. ASCEND is also expected to support performance improvements on existing and future propulsion systems across the entire Airbus portfolio, including helicopters, eVTOLs, as well as regional and single-aisle aircraft.

Cryogenic, superconducting system

The ASCEND demonstrator will feature a powertrain comprising:

- Cryo-cooling system;

- Superconducting motor;

- Cryogenically cooled motor control unit;

- Superconducting distribution system, including cables and protection mechanism.

“With the ASCEND demonstrator, we’ll adapt ground-based cryogenic and superconducting technologies to a full electric powertrain to confirm their potential at aircraft level,” explains Ybanez. “Integrating these components will not only be a world first, but also an essential step towards future full-scale tests and flying demonstrators.”

In his Aviation Week article, Dubois explains that the otherwise challenging temperature (-253°C/20 K) of liquid hydrogen becomes a resource when using superconductivity. He also quotes Ybanez:

“A secondary system could use a heat exchanger and a neutral, easier-to-handle fluid such as nitrogen. It could cool the superconducting wiring to the required 70-80K. Developing a suitable insulation, likely to have a diameter of 4 inches, for use on board an aircraft is a major objective of ASCEND. Composite materials will be considered.”

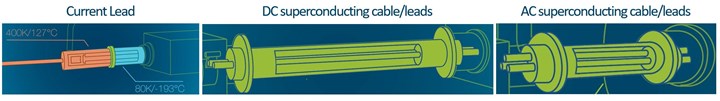

The 4-inch-diameter insulation discussed by ASCEND program head, Lubovic Ybanez, may be used in the linear connection from the Current Lead at left to the Electric Motor at right, see diagrams above. Photo credit: excerpts from Airbus diagram

Liquid hydrogen to cool conventional technologies

As noted by Dubois, with superconductivity, the weight of wiring (which most recently has used aluminum) will no longer be correlated to the power it carries. However, ASCEND’s objectives are not limited to optimizing the weight of the distribution system, but will also seek to significantly increase the power density of the propulsion chain. This is a key consideration as increasing the power of current electrical aircraft systems from a few hundred kilowatts to the megawatts required for a fully electric aircraft is no easy feat — more power not only increases weight and installation complexity, but also generates more heat.

However, with LH2 at 20°K (-253.15°C) helping to maintan the cryogenic (cryo-cooling) system, superconducting components can then work to significantly improve the power density of the electric-propulsion system. Airbus is already advancing how LH2 could be used as fuel for an internal combustion engine or fuel cell as part of its ZEROe pre-program.

The first three pillars of ASCEND, says Dubois, will work on the superconducting motor, the motor control unit and the cryo-cooling system. The motor will be compatible with a propeller, turbine or an unspecified hybrid propeller. The fourth pillar will be network safety and protection, including fault current limiters and circuit breakers. The 15-engineer ASCEND team will study power levels up to multiple megawatts. At the end of the program, the team will issue recommendations so that Airbus can make decisions about electric propulsion architectures as it pursues its ZEROe milestones:

- 2022-23: downselect concepts for demonstrations

- 2025: flight demonstrators completed

- 2025-26: finalize aircraft to develop for entry into service by 2035.

Dubois points out that Safran will become a partner in ASCEND, along with other companies and research laboratories.

“With the ASCEND demonstrator, we’ll pave the way for a real breakthrough in electric propulsion for future aircraft,” says Sandra Bour Schaeffer, Airbus UpNext CEO. “The importance of this work can’t be understated: cryogenic and superconducting technologies could be key enablers to enhancing the performance of low-emission technologies, which will be essential to achieving our ambitious decarbonization targets.”

https://www.airbus.com/newsroom/stories/ascend-cryogenics-superconductivity-for-aircraft-explained.html

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More