Engel to present pre-series production solutions at Composites Europe

In partnership with Schöfer, Engel has developed a pre-series manufacturing cell for the manufacture of thermoplastic fiber-reinforced components using the in-situ polymerization technology.

At Composites Europe 2016, which takes place from Nov. 29th to Dec. 1st in Düsseldorf, Engel will present pre-series production solutions for the automobile, teletronics and technical component sectors.

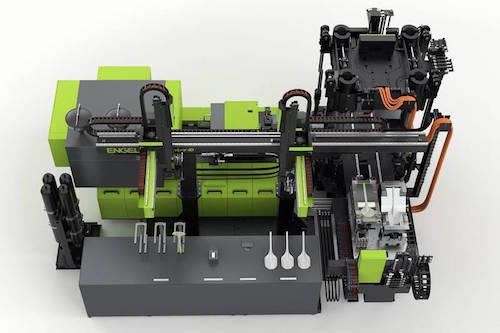

In partnership with Schöfer (Schwertberg, Austria), Engel has developed a pre-series manufacturing cell for the manufacture of thermoplastic fiber-reinforced components. Representing the wide range of possible applications, shovels are produced on the Engel v‑duo 1560/700. The clamping unit is equipped with a sliding table fitted with two mold halves for optimal accessibility. Dry, pre-shaped reinforcing fabrics are inserted into the first cavity and infiltrated with the reactive matrix. To do this, the solid ε-Caprolactam is melted and metered in the reactive unit. Thanks to the monomer's low viscosity in the molten state, the dry fibers can be wetted particularly well. A highly resilient composite is thus formed when polymerizing to polyamide 6. Since reactive processing takes place below the polymer's melting temperature, the composite semi-finished product can be transferred to the second cavity immediately after it was produced where it is functionalized by injection molding. Reinforcing ribs and contours of short glass fiber-reinforced PA 6 are injected to achieve this. Polymerization and injection molding take place parallel to each other. An Engel viper 40 double robot takes over handling the fiber preforms and finished parts as well as transferring the semi-finished products.

With its v-duo series, Engel has developed a relatively compact, energy-efficient machine specifically for fiber composite applications and multi-component processes with fiber preforms, and one which facilitates particularly cost-effective production solutions. Its vertical clamping unit can be accessed from all four sides instead of just two. When processing dimensionally unstable semi-finished fiber products in particular, it is often advantageous to work in the direction of gravity.

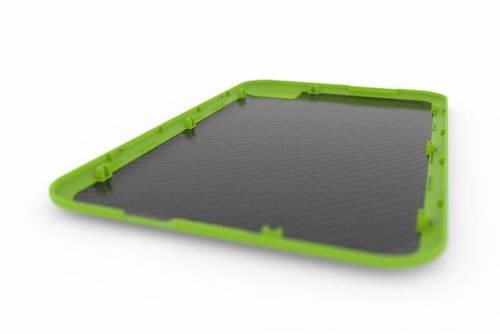

Another key focus of Engel’s stand will be the processing of thermoplastic, continuous fiber reinforced semi-finished parts (thermoplastic fabrics) via the injection molding process. Engel will use components and videos in Düsseldorf to present an example from the teletronics industry. In the production of notebooks, tablets, smartphones and other hand-held devices, the use of innovative composite materials for housings is key to reducing weight and improving stability. Together with its partners Bond-Laminates (a LANXESS Group company based in Brilon, Germany) and LEONHARD KURZ (Fürth, Germany), Engel has succeeded in developing a highly efficient production cell for the manufacture of exceptionally robust housings with high quality surfaces using extreme thin-wall technology. With a wall thickness of only 0.6 mm, the demonstration part reveals completely new possibilities.

The highly automated production cell was specifically designed for the material combination of a thermoplastic, continuous fiber reinforced semi-finished part (Tepex) and the IMD film developed and patented by Bond-Laminates and LEONHARD KURZ. The system solution incorporates three processing technologies to support the in-mold decoration of thermoplastic composite components in mass production: Engel organomelt for shaping and functionalizing thermoplastic fabrics in an injection molding process, Engel variomelt for optimizing surface quality through variothermal mold temperature control and in-mold decoration (IMD) for optical and functional surface finishing directly in the injection mold. At the heart of the production cell is an Engel insert 500V/130 single injection molding machine, an Engel easix six-axis robot and an infrared oven for heating the thermoplastic fabrics, which was also developed and built by Engel.

What makes the new method special is the fact that the continuous fiber-reinforced, semi-finished thermoplastic material is shaped, overmolded and given a high-quality surface decoration in a single processing step. To attain a direct material bond between the thermoplastic fabric and the IMD film, Bond-Laminates and LEONHARD KURZ further developed the materials, the mold and the technology required to process them, thus paving the way for a high degree of process integration. To achieve a durable and decorated surface finish with the conventional process, composite components must be treated and painted in additional work steps after the injection molding process. Integrated production has eliminated the need for several work steps. In the Engel system solution, both the Engel easix multi-axis robot and the IR oven are fully integrated into the CC300 control unit of the injection molding machine. Therefore the preheating of the semi-finished products can also be centrally controlled from the IMM display. Temperatures and heating times are stored together with the data of the injection molding process, which simplifies the documentation, evaluation and tracking of the overall process.

Engel IR ovens are characterized by very high thermal homogeneity, with the various heating zones individually defined and regulated. They are available in five sizes, up to a heating surface of 1,110 x 1,610 mm; to give an example, this will facilitate the processing of large semi-finished parts for complete door modules or front ends for the automobile industry.

The Center for Lightweight Composite Technologies established in 2012 by Engel in St. Valentin, Austria provides an interdisciplinary platform for collaboration with customers, partner enterprises and universities. Core areas of activity include the processing of thermoplastic semi-finished parts (thermoplastic fabrics and tapes) and thermoset compression molding materials such as SMC along with reactive technologies using thermoset and thermoplastic systems (such as HP-RTM and the in-situ polymerization of ε-Caprolactam).

Engel is expanding the capacity of its Center for Lightweight Composite Technologies in order to widen its range of applications and technologies still further. A second (larger) Engel v-duo 1700 machine with clamping force of 17,000 kN is already in service. The machine is equipped with an injection unit, an Engel easix robot and a high pressure metering system for reactive process technology, and may be combined with the IR oven developed by Engel. It is available for both development work and customer trials at the Engel premises in St. Valentin.

Related Content

McClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

Read MoreDesigning an infused, two-piece composite baseball bat

With its Icon BBCOR bat, Rawlings leveraged its experience in braided fabrics and RTM to create an optimized, higher-performance two-piece design.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More