First Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

JAL Airbus A350-900 at Tokyo Haneda. Photo Credit: Aviation Week

On Jan. 2, it was confirmed that an Airbus (Toulouse, France) A350-900 operated by Japan Airlines, and a Japanese Coast Guard De Havilland Canada Dash 8, were involved in an accident during flight JAL516 from Sapporo New Chitose Airport to Haneda International Airport.

The A350 collided with a DHC-8 aircraft shortly after its touch-down in Haneda. All 367 passengers and 12 crew members on-board evacuated the aircraft, but Japanese authorities have since confirmed that five of the six people on board the DHC-8 did not survive. The exact circumstances of the event are still unknown, and marks the first ever A350 hull-loss and Japan Airlines’ first accident since 1985.

The aircraft involved in the accident, registered under the number JA13XJ, was MSN 538, delivered to Japan Airlines from the production line on Nov. 10, 2021. It was powered by Rolls-Royce Trent XWB engines.

In line with International Civil Aviation Organization (ICAO) Annex 13 recommendations, Airbus says it will provide technical assistance to the Bureau d’Enquêtes et d’Analyses (BEA) of France and to the Japan Transport Safety Board (JTSB) in charge of the investigation. For this purpose, Airbus is presently dispatching a team of specialists to assist authorities.

In a report made by Aviation Week on the matter, the aircraft “was crossing the runway threshold at a normal approach speed of 122 knots and touched the ground shortly thereafter. Airport video footage shows how the aircraft was traveling down the initial part of the runway, when suddenly it appeared to hit an obstacle with large flames erupting,” collapsing the nose gear.

A JAL statement notes that no issues or irregularities were encountered, from takeoff to when the A350 pilots acknowledged and repeated the landing permission from air traffic control. Airbus says that updates will be provided as soon as consolidated information is available.

Related Content

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

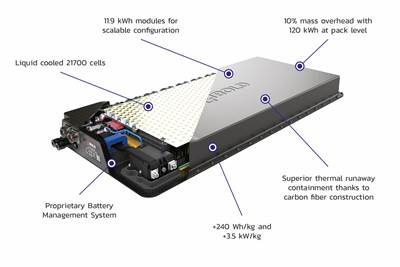

Withstanding fire without the weight

New composites meet stringent fire requirements while lightweighting ships, rail cars and battery boxes for electric cars and planes.

Read MoreDeveloping fire-resistant resins for composites

Ashland, Polynt-Reichhold and Scott Bader discuss chemistries, applications and future developments for FR composites.

Read MoreTroubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

Read More